I build small power that feels big. I build it clean. I build it quiet. I build it to last. I use a 6mm diameter slotless BLDC motor to make this real.

At Jimi Technology Co., Ltd., I turn electric power into straight line motion. I raise. I lower. I push. I pull. I tilt. You press a button. The job gets done. I am not just a seller. I am an expert. I am a solution maker. I am a guide you can trust in automation.

What is a 6mm Diameter Slotless BLDC Motor?

Let me make it simple.

- It is a miniature BLDC motor.

- It is a micro BLDC motor.

- It is a small brushless motor with brushless DC technology.

- It uses electronic commutation. No brushes. No sparks.

- It has a slotless design. The stator winding is ironless. That is why we say coreless BLDC motor.

- The rotor spins with neodymium magnets.

- A 6 mm body is tiny. This is miniaturization in action.

You get no-cogging motor feel. You get smooth rotation motor motion. You get high-speed micro motor reach. You get precision BLDC motor control. You get high efficiency BLDC duty.

I use it in fine tools. I use it in medical devices, robotics, aerospace, drones (UAVs), optics, endoscopy, and dental equipment. I use it in laboratory automation too. This is precision engineering in a tiny can.

Why Choose Slotless? Big Wins in a Tiny Space

You want calm motion. You want long life. You want power you can steer. Slotless gives you that.

- No Cogging Torque. With an ironless stator you feel no “step.” That gives reduced cogging torque and low ripple torque. You get smooth speed control at a crawl.

- High Efficiency. No iron teeth means lower iron loss. You get improved efficiency motor output.

- Low Noise. It runs as a low noise motor with quiet operation.

- High Power Density. This is a high power density motor in 6 mm.

- Long Life BLDC. No brushes to wear.

- Excellent Dynamic Performance. Low inertia of motor helps quick start and stop.

- Vibration reduction. That helps in haptics and optics.

- Clean builds. Ideal for cleanroom application motor needs.

- Sterilization ready options. I can guide sterilization compatible motor and autoclavable motor builds for surgical instruments. Use in autoclave with the right spec.

Quick Specs You Can Use

I give you clear numbers you can plan with. These are typical ranges I see in the market from top makers.

| Spec | Typical Range | Notes |

|---|---|---|

| Diameter | 6 mm | Tiny and light |

| Speed (no load) | Up to 100,000 RPM | Based on winding and voltage |

| RPM range 6mm BLDC | 1,000–80,000 RPM | Stable with good control |

| Voltage | 3–12 V | Check your bus spec |

| Current consumption micro motor | 50–200 mA (no load to nominal) | Model dependent |

| Continuous torque | 0.2–1.0 mNm | Check duty cycle |

| Peak torque | 2–6 mNm | Short bursts |

| Start-up torque | Model dependent | Gear helps |

| Efficiency | 60–80% typical | Better with FOC |

| Bearings | Ball or sleeve or ceramic | Pick for life and noise |

| Operational temperature range | -20°C to +60°C typical | Higher on request |

| Ingress protection (IP rating) | Up to IP54 typical | Custom higher |

| Weight | A few grams | Varies with gear or encoder |

Key electric constants help design.

- Torque constant (Kt).

- Voltage constant (Kv).

- Back EMF constant.

- Motor resistance.

- Motor inductance.

- Mechanical time constant.

- Electrical time constant.

- Thermal resistance motor.

I map these to your load and your motor lifespan calculations. I size right from the start with a clear motor sizing guide.

Visual: Tiny Motor Scorecard

Efficiency: ██████████ 80%

Noise: ███████████ Very low

Speed: ███████████ Ultra fast

Smoothness: ███████████ No cogging

Power density: ███████████ Very high

(Bar length is a simple view. It helps you see trends fast.)

Where This Motor Shines

You need small. You need strong. You need clean. This motor fits.

- Medical & Health

- Medical device motor use.

- Surgical tool motor for scopes.

- Drug delivery system motor for a pump.

- Medical pump BLDC and pump motor 6mm.

- Pipette motor in laboratory automation.

- Ophthalmic device motor.

- Dental handpiece motor.

- Endoscopy tools.

- Autoclavable motor builds for sterilization.

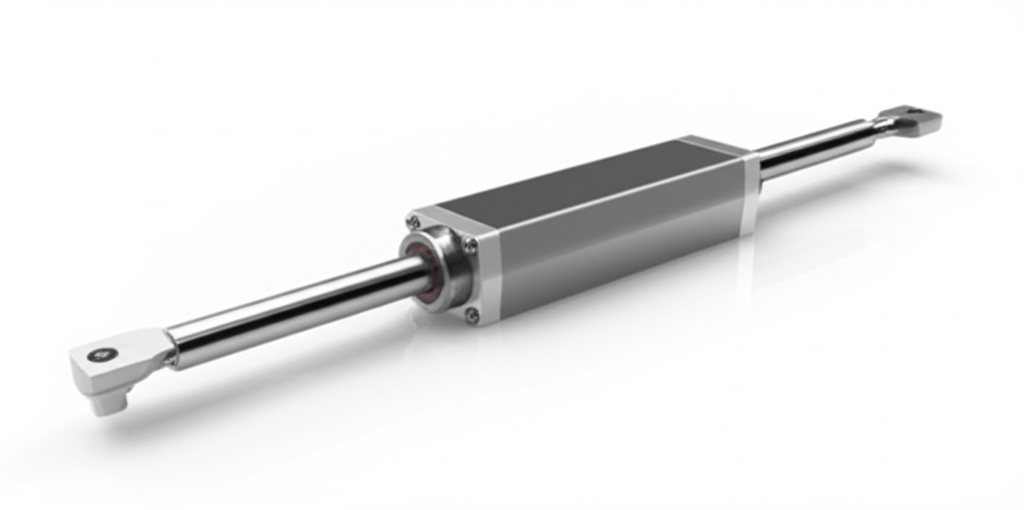

- Robotics & Motion

- Robotic actuator.

- Micro robotics motor and micro-actuator.

- Linear actuator 6mm for tiny strokes.

- Miniature gear motor with planetary gearhead 6mm.

- Precision positioning motor for optics.

- Haptic feedback motor for touch.

- Aerospace & Defense

- Drone micro motor for nano UAVs.

- Aerospace micro motor flight subsystems.

- Defense applications BLDC in guided tools.

- Gimbal and optical instrument motor.

- Consumer & Industry

- Wearable tech motor.

- Portable instrument motor.

- Handheld device motor.

- Miniature motion control in industrial automation motor lines.

- Miniature motor manufacturing for compact motor solutions.

- Valves and valve actuation motor.

- Micro-fluidics motor in labs.

- Optics and cameras.

How I Make It Work For You

I match motor. I match drive. I match mechanics. You get a system that fits and runs.

- Control and Drive

- BLDC motor driver with PWM control BLDC.

- Field-Oriented Control (FOC) for smooth torque.

- PID control for tight speed and position.

- Sensorless BLDC control when you need simple wiring.

- Hall effect sensors for low speed lock.

- Encoder choices and encoder options micro motor for fine steps.

- Gears and Load

- Gearhead integration for torque.

- Planetary gearhead compact build.

- Match winding configurations to speed and torque needs.

- Hardware and Build

- Bearing types micro motor. Pick ball bearings micro for life. Pick sleeve bearings small for cost and quiet. Pick ceramic bearings for special duty.

- Motor mounting options keep parts tight.

- Electrical connectors micro and lead wire types to suit your harness.

- Magnet material motor set by need.

- Manage heat dissipation micro motor via the case and the path.

- Watch electromagnetic interference (EMI) and add filters as needed.

- Set the operational temperature range and the IP rating to match the field.

I bring it all together in clean kits you can buy and use. If you want a tiny actuator ready to go then see my brushless DC actuators for micro automation from Jimi. I also ship smart driver kits and control gear. You get help from specs to sample to scale.

- Explore brushless DC actuators for medical and micro robotics: High‑precision brushless DC actuators

- Pick a light and tiny stage: Light‑duty miniature actuators

- Add the brains that run your motor: BLDC motor drivers and actuator controllers

- Build out a line with ready systems: Industrial automation actuators

How to Choose The Right 6mm Slotless BLDC

I ask a few clear questions first.

- What torque do you need. Continuous torque and peak torque both matter.

- What speed do you need. Set your speed (RPM) window and your no load target.

- What bus do you have. Set voltage and allowed current. Note your voltage requirements BLDC and current consumption micro motor limits.

- What run time do you need. Map duty cycle and cool time.

- What space and weight do you have.

- What environment do you face. Note ingress protection (IP rating), shock, and operational temperature range.

- Do you need sensorless BLDC control or Hall effect sensors or an encoder.

- Do you need a planetary gearhead 6mm.

- Do you need DC motor alternatives. I can weigh brushed vs brushless for you.

I then use a motor sizing guide. I pick a winding to fit your bus. I set Kv, Kt, back EMF, inductance, and resistance to hit your curve. I check mechanical time constant and electrical time constant for response. I check thermal resistance to keep heat in line. I do the motor lifespan calculations so you get years of calm use.

The Future of Miniature Motion

Good news. The small world gets better by the day.

- Advanced motor materials boost power and life.

- Better magnet material motor and low loss wire help.

- New FOC chips from Trinamic Motion Control (now Analog Devices) raise smoothness.

- Smart sensorless tech expands reach.

- More integrated motor & driver sets shrink boards.

- Stronger miniature motor manufacturing methods raise power density and trim cost.

Why Work With Me at Jimi

You need a partner who sees the whole build. I do. I ship automation systems you can bolt in. I merge the tiny 6mm slotless BLDC motor with the right linear actuator, TV lift, or custom frame. I make sure the actuator, the controller, and the gearhead all sing in tune. You get speed. You get force. You get quiet. You get trust.

- I guide you from spec to test to mass build.

- I speak motor. I speak drivers. I speak controls.

- I deliver kits with actuator controllers, power, switches & remotes, and mounts.

- I support DIY projects & robotics as well as full industrial automation rollouts.

If you need a tiny micro‑drives pack that just works then I am ready. If you want custom micro motors to fit a hard space then I can design that too.

Example Use Paths

- A drug delivery system motor that must be silent. I pair a slotless 6 mm unit with FOC and a planetary gearhead 6mm. I add an encoder for dose count. I tune PID control for soft starts.

- A precision optics zoom ring. I use a no-cogging motor with back EMF constant matched to low Kv. I pick ball bearings micro for life.

- A wearable tech motor for haptics. I choose a high-speed micro motor with smooth rotation and quiet operation. I limit EMI with filters.

- A valve actuation motor in a lab tool. I set ingress protection and check thermal resistance. I use sleeve bearings small for low noise or ceramic bearings for harsh duty.

Brands You Know. Proof I Know The Field.

I study the best. I benchmark with data from makers like Maxon Motor, Portescap, Faulhaber, Namiki Precision Jewel Co., Ltd., Koshin Co., Ltd., Nidec Corporation, Allied Motion Technologies, PITTMAN (AMETEK), DCX Motors, and Micro‑Motor AG. I read driver notes from Trinamic Motion Control (now Analog Devices) too. I use this knowledge to improve your build.

A Note on Specs and Safety

I size for your load. I test. I watch heat and heat dissipation micro motor paths. I set motor mounting options for strength. I match electrical connectors micro and lead wire types to your harness. I check power output 6mm motor vs torque density BLDC needs. I plan for vibration reduction. I do real tests before you ship.

Let’s Build Your Motion

Tell me what you need to move. I will help you pick the right 6mm diameter slotless BLDC motor. I will pair it with the right gearhead, driver, and actuator. I will help you make it smooth. I will help you make it safe. I will help you make it last.

You get clear steps. You get fast help. You get a partner.

References

- maxon group. ECX SPEED 6. Application notes and datasheets.

- FAULHABER. Micro brushless and coreless motor families. Technical data and guides.

- Portescap. Micro BLDC portfolios and motion solutions.

- Namiki Precision Jewel Co., Ltd. Micro motors for medical and optics.

- Allied Motion Technologies. BLDC motor and driver application notes.

- Analog Devices (Trinamic Motion Control). FOC and motion control IC documentation.