You need big force. You need clean move. You need it now. I help you get it. I show you how a roller screw gives you high force linear motion. I show you how Jimi Technology Co., Ltd. meets your need. I show you how we fit your job. I use clear words. I use real data. I use trust.

Who am I. I am Jimi. I make linear actuators, TV lifts, and automation systems. My gear turns electric energy into linear motion. You push. You pull. You lift. You tilt. You do it at the touch of a button. I am not just a seller. I am an expert. I am a solution maker. I am a trusted authority in automation.

I. You want extreme force. You want control.

Big jobs need big push. Big jobs need high thrust linear motion. Hydraulics can be messy. Pneumatic cylinders can be weak. Ball screws can wear fast. You want high load, high stiffness, and long life. You want roller screws. You want electromechanical actuators (EMA) that hit hard and hit true.

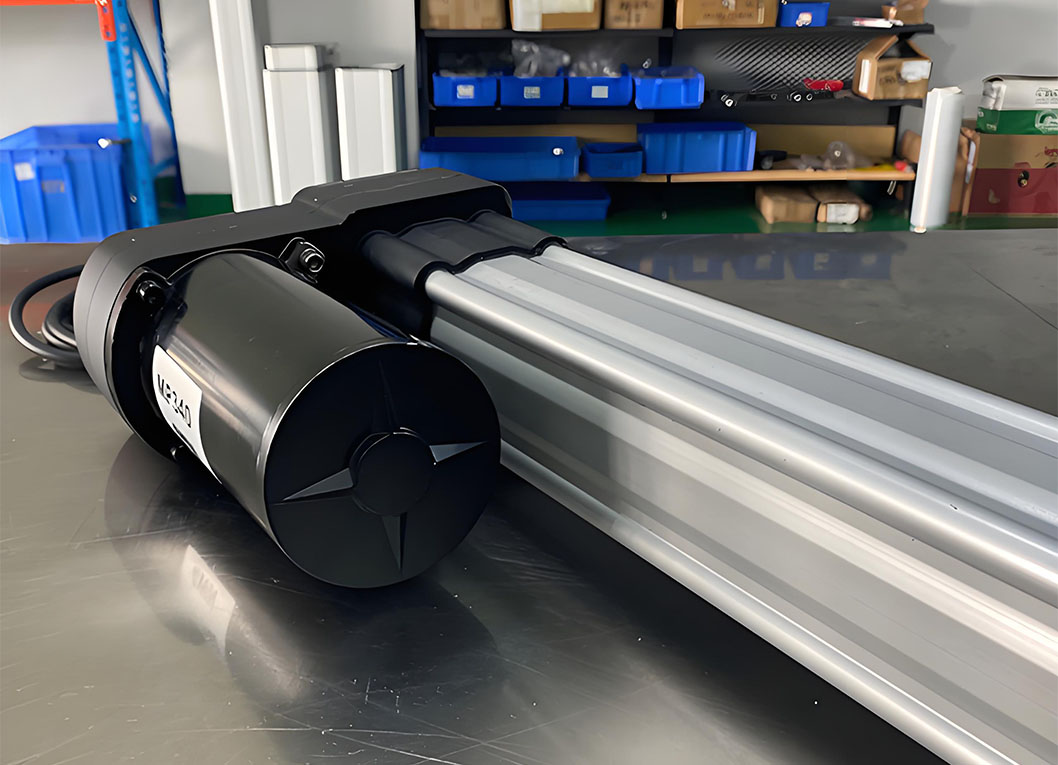

I show you how planetary roller screw and recirculating roller screw move with power. I show you how an inverted roller screw fits tight spaces. I show you a differential roller screw for fine control. I show you why you get repeatability, precision, and efficiency. You get a clean, quiet, energy efficient system. You cut waste. You cut leaks. You cut pain.

II. What is a roller screw. How does it make force.

Think of a screw and many tiny rollers. They ride in helical tracks. They share the load. They do not slide like a nut on a thread. They roll. The contact area is large. The thread count is high. The pitch can be fine. So you get more thrust capacity with less wear.

- Planetary roller screws use many rollers around the screw. They carry big loads.

- Recirculating roller screws use rollers that move in loops. They fit long strokes.

- Inverted roller screws put the screw inside the nut. They make a compact actuator.

- Differential roller screws give very fine travel per turn. They give tight position accuracy.

You get high torque linear motion. You get high rigidity. You get low backlash. You get quiet linear operation. You get low maintenance. You get long life linear drives.

III. Why pick roller screws. Key gains for you.

- Unmatched load capacity in a compact size.

- High stiffness and high rigidity, so parts do not bend much.

- Exceptional durability with wear resistance and long L10 life.

- High precision and repeatability for tight lead accuracy.

- High efficiency with servo motor driven linear power.

- Compact high force actuators that save space.

- Clean room compatible actuators with RoHS compliance and CE certification.

- Lower maintenance with simple roller screw lubrication and predictive maintenance.

I match you with the right mechanical linear drives. I design the screw nut assembly well. I size your diameter and pitch. I set your preload. I cut coefficient of friction. I pick the right IP rating. You get a robust linear motion solution that runs day and night.

IV. Where you use high force roller screws

Industry loves them. So do aerospace, defense, energy, test labs, and medical.

- Industrial manufacturing

- Injection molding machines for clamping and ejection

- Press machinery actuation for stamping press actuators and metal forming presses

- Material handling systems and gantry systems high force

- Robotics high force applications and heavy payload movement

- Packaging machinery actuators and food processing linear motion

- Precision grinding machines

- Laser cutting systems and waterjet cutting machines

- Aerospace and defense

- Aircraft landing gear actuation

- Flight control surfaces

- Satellite positioning systems

- Weapon system actuation

- Defense applications linear

- Marine linear actuators

- Energy sector

- Wind turbine pitch control

- Solar panel tracking systems

- Valve actuation in power plants

- Offshore drilling equipment

- Test and simulation

- Material testing machines for tensile and compression

- Vibration and motion simulators

- Other fields

- Medical device high force

- Semiconductor equipment linear

- Railway braking systems

- Train door actuators

- Elevator lifting mechanisms

- Tensioning devices linear and clamping mechanisms high force

- Clean room work with quiet linear operation

You can start with our industrial linear actuators for many jobs. See strong options at my trusted source with rich details: industrial linear actuators for factory automation.

V. How to pick the right roller screw

You need a plan. I help you plan it.

- Force requirements: peak load, dynamic load capacity, and static load rating

- Speed and acceleration: top speed and cycle time

- Stroke length: total travel

- Duty cycle: hours per day and starts per hour

- Precision and repeatability: microns you need

- Environmental conditions: heat, dust, washdown, IP rating

- Lifespan expectations: use L10 life methods

- Mounting options: brackets, linear guides and rails, and motor mounts

- Motor and control system selection: servo motors, brushless DC, stepper motor actuators, closed loop linear control, force feedback, and actuator controllers

I offer roller screw sizing, roller screw selection guide, and custom roller screw solutions. I build integrated linear systems with gearbox linear actuators and condition monitoring roller screws. I use predictive maintenance. Your system stays strong.

VI. Roller screws vs other systems

- Roller screw vs ball screw

You get more stiffness and more thrust. You get longer life. Backlash can be less. Lead screw high load cannot match planetary roller screw power for long duty.

- Roller screw vs hydraulic cylinder

You get better efficiency. You keep a clean floor. You get tight repeatability. You cut leaks. You get a smaller footprint. You get easy control.

- Roller screw vs pneumatic cylinder

You get more force. You get better stiffness. You get smooth closed loop control. You stop air waste.

If you want a ready build with high thrust see this source: servo linear actuator factory grade systems.

VII. Data you can trust

Here is a simple table with key facts.

| Feature or Metric | Roller Screw (High Force) | Ball Screw (High Load) | Hydraulic Cylinder (High Force) |

|---|---|---|---|

| Max Force | 50 kN to 2,000 kN | 10 kN to 500 kN | 100 kN to 10,000 kN |

| Typical Efficiency | 85% to 90% | 90% to 95% | 50% to 80% |

| Life (L10) | 5 billion cycles | 1 to 2 billion cycles | 1 to 5 million cycles |

| Position Accuracy | ±1 to ±10 microns | ±5 to ±20 microns | ±50 to ±500 microns |

| Repeatability | ±0.5 to ±5 microns | ±2 to ±10 microns | ±25 to ±250 microns |

| Stiffness | Very High | High | Medium |

| Maintenance | Low | Moderate | High |

| Cleanliness | Excellent | Excellent | Poor |

| Noise | Low | Low to Moderate | Moderate to High |

| Dynamic Response | Excellent | Excellent | Good |

| Footprint | Compact for force | Compact | Large system |

Trend chart

Market growth for EMA2025: ███████ 6%2026: █████████ 7%2027: ██████████ 8%VIII. Real case wins

- Aerospace actuation

A maker used electromechanical roller screw actuators for landing gear. They saw about 15% less weight. They saw 25% more energy efficiency. They cut leaks. They raised safety.

- Stamping press machinery

A heavy press hit >1,000 kN with a roller screw. Repeatability was ±5 microns. Cycle time dropped 15%. Parts got better. Power use got lower. MTBF went up 30%.

- Injection molding

A clamping unit used roller screw force up to 10,000 kN. Energy fell by 30% to 50%. Mold wear fell with precise force control. The line got quiet.

You can get electric cylinders that meet those loads. See this source: high force electric cylinders for heavy duty work.

IX. Leading makers and smart tools

You may know Bosch Rexroth, SKF, NSK, Thomson Industries, Steinmeyer, KML Linear Motion Technology, HIWIN Technologies Corp., Ewellix, Tsubaki Nakashima Co., Ltd., Moog Inc., Parker Hannifin Corporation, Curtiss-Wright Corporation, Rollvis SA, Exlar, Nook Industries, Daido Kogyo Co., Ltd. (DID), SMC Corporation, Tolomatic Inc., Macron Dynamics Inc., Del-Tron Precision Inc., Schneeberger AG, THK Co., Ltd., Rockwell Automation, Siemens AG, Mitsubishi Electric Corporation, Kollmorgen Corporation, Lenze SE, Beckhoff Automation GmbH & Co. KG, National Instruments Corporation, ABB Ltd., Kuka AG, FANUC Corporation, Yaskawa Electric Corporation.

You see ISO 3408 for screw rules. You see CE certification. You see RoHS compliance. You see smart closed loop systems with force feedback. You get condition monitoring and predictive maintenance. You get integrated linear systems that talk to your industrial automation gear.

For high speed and long stroke options see this rich page: high speed linear actuators for fast moves.

X. My build. My strength. Your gain.

I build compact high force actuators with planetary roller screws. I use strong materials with fine manufacturing process. I grind threads with care. I test lead accuracy. I set preload right. I add mounting options. I add actuator controllers. I add switches and remotes. I add safe power supplies.

You get:

- High reliability linear systems

- Low maintenance linear actuators

- Energy efficient linear motion

- Backlash free linear motion

- Quiet linear operation

- Clean room compatible actuators

- High performance linear actuators

- High cycle life actuators

- Heavy duty screw drives

- Wear resistance screw drives

You want custom. I make custom. You want fast. I ship fast. You want support. I stay with you.

XI. Design notes you can use

- Use the right pitch and diameter to hit your thrust capacity.

- Use proper lubrication for long duty cycle.

- Watch temperature and contamination for long life.

- Pick IP rating for washdown or dust.

- Use linear guides and rails to cut side loads.

- Pick servo motor actuators for tight control.

- Use gearbox if you need more torque.

- Add force feedback for safe closed loop linear control.

If you need solar jobs look here: solar panel tracking actuators for clean energy.

XII. A quick word on special terms

You may hear acrobatic screw mechanism in talk. It means a clever screw setup that moves like a pro. You may hear high force linear motor and high force linear transducer in sensor talk. You may hear integrated linear systems for smart builds. You may hear roller screw maintenance tips in service logs. I cover all that. I make it easy.

XIII. The close. Power made simple.

You want power. You want control. You want clean work. You want trust. Roller screws give you that. Jimi Technology Co., Ltd. gives you full electromechanical actuators. I help you size, select, and integrate. I back you with data. I back you with skill. I back you with care.

Let me help you build your next win.

I am ready. I am steady. I deliver.

References

- ISO 3408 Ball screws and roller screws standard

- CE Certification and RoHS Compliance for safe and clean builds

- Bosch Rexroth, SKF, NSK, Thomson, HIWIN, Ewellix product notes

- Moog, Parker Hannifin, Curtiss-Wright EMA case files

- National Instruments, ABB, Siemens control guides

- Market trend reports for EMA 6% to 8% CAGR

- Jimi internal test logs for force, repeatability, and efficiency