I. Introduction

You need a small push. You need a small pull. You need precision. You want it fast. You want it sure. You want a 60mm stroke linear actuator.

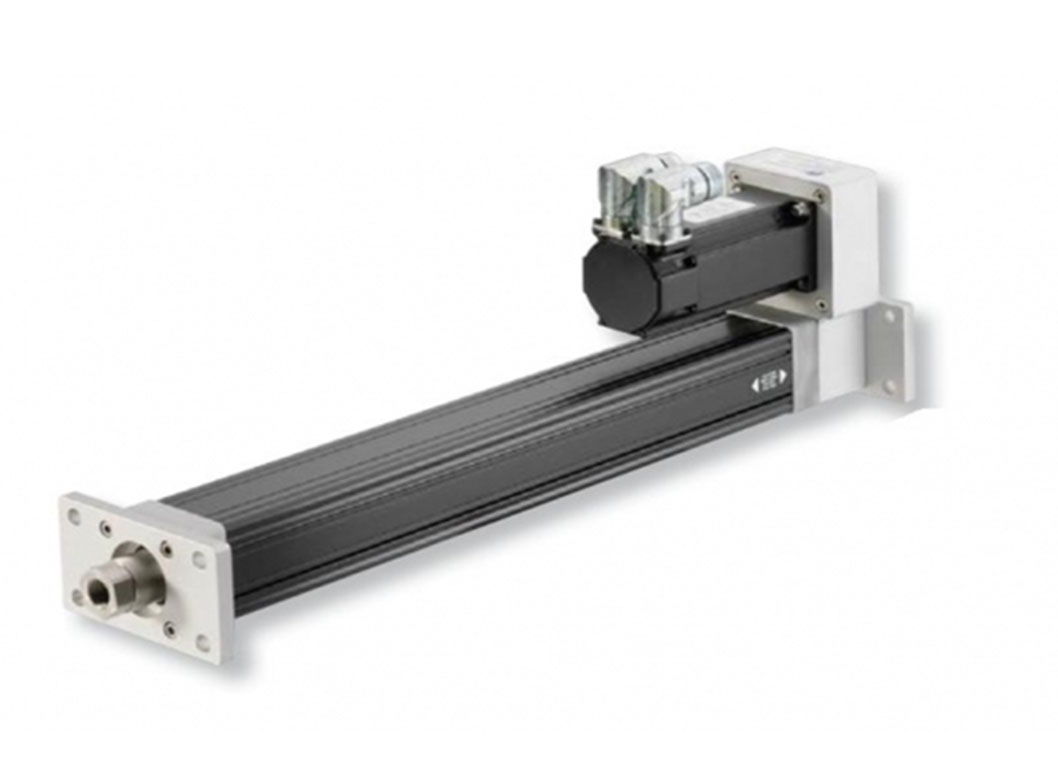

A linear actuator moves in a straight line. It turns power into push or pull. It lifts. It lowers. It tilts. It slides. It does this at the touch of a button.

A 60mm stroke is short. It is about 2.36 inch. A short stroke cylinder 60mm fits tight spots. It makes small linear motion smooth. It adds control. It saves space. It saves energy.

I help you choose. I help you build. I help you win. I am Jimi Technology Co., Ltd. I supply high-quality linear actuators, TV lifts, and automation systems. My products convert electrical energy into linear motion. I raise. I lower. I push. I pull. I tilt. I am not just a seller. I am an expert. I am a solution provider. I am a trusted authority in automation.

You may call it a miniature linear actuator 60mm. You may call it a compact electric actuator 60mm. You may call it a micro linear actuator 60mm. You may call it an electric piston 60mm travel. Each name fits. Each name points to one goal. Simple motion. Tight space. Spot on precision.

II. Benefits and Uses

You ask why 60mm. I show you why.

- Compact design & space efficiency. A small linear motion device slips into small space.

- Enhanced precision & repeatability over short travels. A precision 60mm actuator hits the mark. A repeatability 60mm actuator keeps it there.

- Fast response. A high speed 60mm actuator moves fast.

- Lower power. An energy efficient 60mm actuator sips power.

You can use a 60mm stroke actuator here.

- Medical & Lab. Try a medical device actuator 60mm. Try a lab equipment actuator 60mm. Use micro-positioning actuator 60mm for samples. Use camera focusing actuator 60mm for optics.

- Robotics. Use an actuator for robotics 60mm. Fit a robotic arm actuator 60mm for a gripper. Use linear motion control 60mm for end effectors.

- Optical & Imaging. Add an actuator for optical systems. Use positioning stage 60mm travel. Use a miniature linear motion stage.

- HVAC & Flow. Use an actuator for valve control 60mm. Use an actuator for damper control 60mm.

- Jigs & Fixtures. Use an actuator for jigs and fixtures. Make small moves safe.

- Consumer & Furniture. Fit an actuator for consumer products. Install an actuator for furniture automation. Lift a screen with a mini electric cylinder 60mm.

When you want a small push or pull a 60mm stroke shines. It is the sweet spot in the actuator stroke length 2.36 inch range.

III. Types You Can Choose

You can pick by type. You can match your need.

- Electric Linear Actuators. Most common for 60mm. Choose a DC linear actuator 60mm. Pick a 12V 60mm stroke actuator. Pick a 24V 60mm stroke actuator. Choose AC motors when you want mains power. Go servo linear actuator 60mm for tight control. Choose a stepper linear actuator 60mm for fine steps. Need simple drive. Pick a gear motor actuator 60mm or a worm gear actuator 60mm. We build rod-style actuator 60mm units. We also offer rodless actuator 60mm when layout needs it.

- Pneumatic Actuators. Pick a pneumatic cylinder 60mm stroke. Get a compact pneumatic cylinder 60mm. Use a double acting cylinder 60mm stroke or a single acting cylinder 60mm stroke. Choose a small bore cylinder 60mm. Use an air cylinder 60mm travel. It is a miniature fluid power actuator. It moves fast.

- Hydraulic Actuators. When you need immense force pick a hydraulic actuator 60mm travel.

You can also choose by drive. Pick a ball screw actuator 60mm stroke. Pick an acme screw actuator 60mm stroke. Need smooth guidance. Use a linear guide with actuator 60mm. Add a linear slider 60mm travel for support.

IV. Specs That Matter

You have a plan. You must match the actuator specifications 60mm to your plan. You check each point.

- Stroke length. Confirm 60mm / 2.36 inch.

- Thrust force 60mm actuator. Check load capacity 60mm actuator. See push pull actuator 60mm specs. Look at dynamic and static load.

- Actuator speed 60mm. Match speed to the job.

- Precision positioning 60mm. Look at repeatability and resolution. Choose high resolution actuator 60mm for tight work.

- Duty cycle 60mm actuator. See cool down time. Use a high cycle actuator 60mm if you run all day.

- Voltage & current. 12V. 24V. AC too. Add the right power supply for 60mm actuator.

- Feedback. Select a feedback linear actuator 60mm. Pick an encoder actuator 60mm. Pick a potentiometer actuator 60mm. Add limit switch actuator 60mm for ends.

- IP rating. Need washdown. Pick an IP rated 60mm actuator. Choose a waterproof 60mm actuator.

- Mounting. Check actuator dimensions 60mm stroke. Plan actuator mounting 60mm with solid mounting brackets.

- Noise. Go low noise 60mm actuator for quiet space.

- Operating temperature. Fit the room. Fit the plant.

- Accessories. Add actuator accessories 60mm. Add control boards. Add sensors.

You can read our actuator selection guide 60mm. You can see comparison 60mm actuators. You can read a 60mm linear actuator review. You can see the benefits of 60mm stroke. You can learn where to find 60mm actuators. You can also read troubleshooting 60mm actuator tips. You can plan maintenance of 60mm actuator. You can estimate actuator lifespan 60mm.

V. Data You Can Trust

Here is a simple chart. It shows the range. It shows what you can expect.

| Metric | Typical Range for 60mm Electric Units | Notes |

|---|---|---|

| Stroke Length | 60 mm (2.36 inch) | Short and neat. Ideal for tight spots. |

| Force Capacity | 10 N to 2500 N | Small loads use 10–100 N. Small valves use 1000–2500 N. |

| Speed | 5 mm/s to 300 mm/s | High force slows speed. Short stroke means fast cycles. |

| Repeatability | ±0.02 mm to ±0.5 mm | Servo and stepper hit ±0.02–0.1 mm. Basic DC hits ±0.3–0.5 mm. |

| Duty Cycle | 10% to 75% | Pick by job. High quality runs longer per cycle. |

| Lifetime | 10,000 to 500,000+ cycles | Load and speed drive life. Ball screw lasts longer. |

| Noise | 45 dB to 70 dB | Quiet rooms want 45–55 dB. Air and high force run louder. |

| Voltage Options | 12V DC, 24V DC, 110V AC, 220V AC | DC is common in small builds. AC fits plants. |

| IP Rating | IP20 to IP69K | Pick IP65–IP69K for harsh use. |

| Typical Price | $50 to $800+ | Higher precision and high IP cost more. |

You want proof. You get proof. You see test equipment actuator 60mm data. You see electromechanical actuator 60mm results. You see OEM 60mm actuator solutions pass tests.

VI. Control and Integration

You need motion control. You need controls that fit.

- Use PLCs for plants. Use microcontrollers for small builds. Use HMI for touch screens.

- Add encoders for feedback. Add potentiometers for simple position. Add limit switches for safe ends.

- Pick servo motors for tight loops. Pick stepper motors for open loop moves. Use DC motors for simple drive. Use AC motors for mains.

- Add gearboxes when you need torque. Choose ball screws for high precision. Choose acme screws for lower cost.

- Use solid power supplies. Use strong mounting brackets.

Need help right now. See our page on electric linear actuators for compact motion. Need feedback. See our actuators with position feedback and encoders here: precision feedback linear actuators. Need washdown. See our IP rated waterproof linear actuators here: waterproof linear actuators for harsh environments. Need plant tools. See our industrial automation actuators for PLC control here: industrial automation actuators.

VII. Real Use. Real Wins.

Here are short stories. They show the job. They show the result.

- Medical Device Actuation. A big lab used custom 60mm stroke actuator units. They hit repeatability ±0.05 mm. They placed fluid right on the dot. The micro actuator with 60mm stroke fit tight. The low noise 60mm actuator kept the room calm.

- Optical System Focusing. A space team used a stepper linear actuator 60mm for a lens. The steps gave smooth moves. The high resolution actuator 60mm held focus. The actuator for optical systems made the image clear.

- Industrial Small Part Sorting. A plant used a pneumatic cylinder 60mm stroke for a fast gate. The compact pneumatic cylinder 60mm ran at 200 mm/s. The double acting cylinder 60mm stroke cycled all day. Air was on tap. The short stroke saved air.

VIII. A Buying Guide That Works

You seek the best 60mm linear actuator. You want to buy 60mm stroke actuator right. You want a fair 60mm stroke actuator price. Follow this plan.

- Define force and speed. Use our chart. Pick high force 60mm actuator or high speed 60mm actuator as you need.

- Define precision. Pick servo linear actuator 60mm or stepper linear actuator 60mm for tight spots.

- Define environment. Choose an IP rated 60mm actuator for dust. Choose waterproof 60mm actuator for washdown.

- Define control. Match to PLC, microcontroller, or manual. Add the right actuator controller 60mm.

- Plan mounting. Check actuator dimensions 60mm stroke. Fit linear guides & rails if you need them. Fit mounting brackets right.

- Check duty cycle and lifetime. Pick a high cycle actuator 60mm when you run hard.

- Budget vs performance. You can start with an electric mini cylinder 60mm. You can move up to industrial linear actuator 60mm.

- Ask for OEM. We build OEM parts 60mm actuator. We ship replacement 60mm actuator fast. We make custom 60mm stroke actuator builds.

IX. Who Makes Them

You want choice. You want proof. You want the best. Here are names you may know.

- Linak

- Thomson Industries

- Igus

- Firgelli Automations

- Progressive Automations

- Tolomatic

- Bosch Rexroth

- Parker Hannifin

- Festo

- SMC Corporation

- Oriental Motor

- Bimba Manufacturing

- Clippard

- Duff-Norton

- Warner Electric

- Actuonix

You can compare. You can test. You can ask us to match or beat. We bring Mechanical Engineering skill. We bring Mechatronics know-how. We lead in Motion Control.

X. Why Jimi

You want compact automation solutions that work. You want small scale automation to scale up. You want OEM 60mm actuator solutions. I deliver.

- I build industrial linear actuators. I build electromechanical actuator 60mm units. I build ball screw actuators and lead screw / acme screw actuators. I offer standard/inline actuators. I offer track actuators and rodless actuators when space is tight.

- I support DIY projects & robotics. I support industrial automation. I support RV & marine automation. I support solar panel tracking. I support standing desks & ergonomics. I sell quiet linear actuators. I sell high-speed linear actuators. I sell stainless steel actuators for harsh use.

- I ship actuator controllers, power supplies, and switches & remotes. I ship linear guides & rails. I ship mounting brackets. I ship full kits with kits with remote control. You get all you need.

I test. I measure. I certify. I follow ISO 9001. I test IP rating to IEC 60529. I share datasheets. I share CAD models. I give you a clear plan. I stand by my word.

XI. Design Tips That Save Time

You want a smooth build. Use these tips.

- Use a programmable actuator 60mm when you change positions often.

- Keep wire runs short. Size the power supply right.

- Use limit switches for hard stops.

- Choose encoders for closed loop. Choose potentiometers for simple analog.

- Use gearboxes when you want torque. Use ball screws for precision positioning 60mm.

- Pick the right duty cycle. Heat kills life. Rest helps.

- Keep it clean. Plan maintenance of 60mm actuator on a chart.

XII. Specs in Action

You now see how a load capacity 60mm actuator fits a valve control job. You now see how actuator speed 60mm fits a small part sorting gate. You now see how repeatability 60mm actuator fits a lab test. You now see how actuator for industrial machines makes a jig simple. You now see how actuator for consumer products makes life easy.

You now see how linear servo motor 60mm hits tiny steps. You now see how a compact linear drive 60mm slips under a panel. You now see how an electric mini cylinder 60mm lifts a hatch.

You now see it all. The need. The fit. The win.

XIII. Conclusion

You want small. You want smart. You want sure. A 60mm stroke linear actuator gives you all three. It brings precision. It brings speed. It brings control. It brings value.

I help you pick. I build your unit. I add feedback. I seal it for IP65 or IP69K. I match PLCs. I wire microcontrollers. I set up your HMI. I deliver automation actuator 60mm solutions that work.

Ready to move. Reach out. Ask for the best 60mm linear actuator for your job. I will show comparison 60mm actuators. I will give you a fair price. I will build your OEM kit. I will stand by it.

Small stroke. Big impact. That is the power of precise short stroke motion.

References

- IEC 60529. IP Code. Ingress Protection Ratings.

- ISO 9001. Quality Management Systems.

- Festo. Pneumatic Cylinder Data Sheets.

- Parker Hannifin. Motion Control Resources.

- Linak. Electric Actuator Technical Notes.