Ever seen a robot arm relocation with smooth accuracy, or enjoyed a system rise up effortlessly at the press of a button? That magic comes from electric cylinders and the way they’re mounted. The right install can turn a fundamental actuator right into the powerhouse of your automation system. The wrong one? It can bring about rattles, jams, and early failing. That’s why comprehending installing choices is vital.

Why Mounting Matters for Electric Cylinders

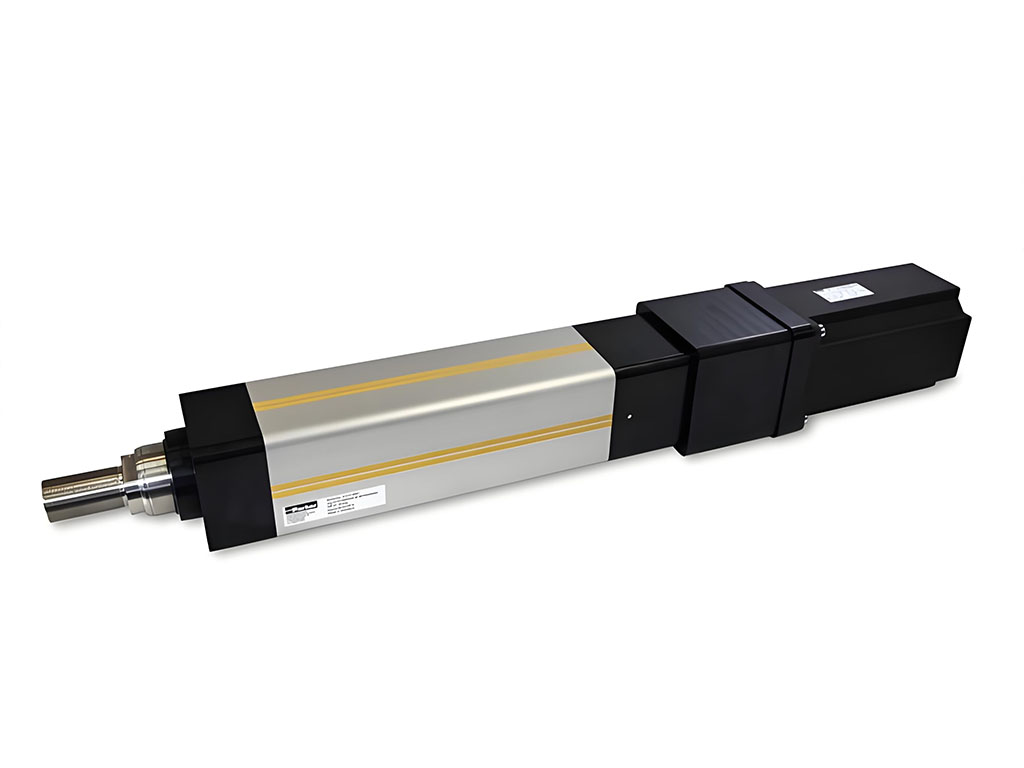

Electric cyndrical tubes, often called straight actuators, make stuff relocate a straight line. They raise, push, draw, and turn everything from packaging equipments to healthcare facility beds. But right here’s where it gets real– just how you affix these gadgets modifications everything. Done right, your actuator lasts longer, functions a lot more smoothly, and keeps your individuals safe. Mess it up? You waste time, power, and cash.

The way you mount an electric cylinder affects:

- Performance: Accurate speed, pressure, and repeatable actions

- Durability: Longer life and much less maintenance

- Safety: Stable devices maintain employees safe

- Cost of Ownership: Less downtime and fewer repair work

This overview discusses usual cyndrical tube installing options, when to use every one, and why correct installing can make or break your automation project.

Key Mounting Considerations: What Should You Watch For?

Start with these big questions:

- What Kind of Load?

- Axial Load: Pushes or draws along the very same line as the cylinder. Think of a moving drawer.

- Radial Load: Pushes from the side. Think of a person leaning on the moving arm.

- Cantilevered Load: Acts off-center, twisting as it relocates.

- Dynamic vs. Static: Is the load moving and transforming swiftly, or simply holding stable?

- What’s the Environment?

- Extreme Temperatures: Cold can stiffen, heat can deteriorate parts.

- Humidity/Washdown: Water or chemicals need sealed or stainless mounts.

- Dust & Debris: Dirty plant? Choose enclosed mounts.

- Vibration & Shock: Busy factory floors need shock-resistant setups.

- Space and Orientation

Have you got room? Or are you working in a tight spot where every millimeter counts?

- Motion Path

Does your cylinder move in a straight line or does it swing in an arc?

- Maintenance Access

Can you reach the actuator for service? Will you need to swap it out fast?

Common Electric Cylinder Mounting Options Explained

Think of mounts as shoes for your cylinders—a bad fit hurts performance and life. Here are your main choices:

Fixed Mountings: Stay Put and Perform

1. Foot Mount (MS1, MS7 – ISO 15552)

Mounting feet bolt to the body, making life simple. If your cylinder pushes/pulls straight in line, foot mounts bring:

- Advantages: Easy install, low cost, solid hold.

- Downsides: Doesn’t forgive misalignment. Too much side force and something may bend.

- Where It’s Used: Packing lines, simple lifts.

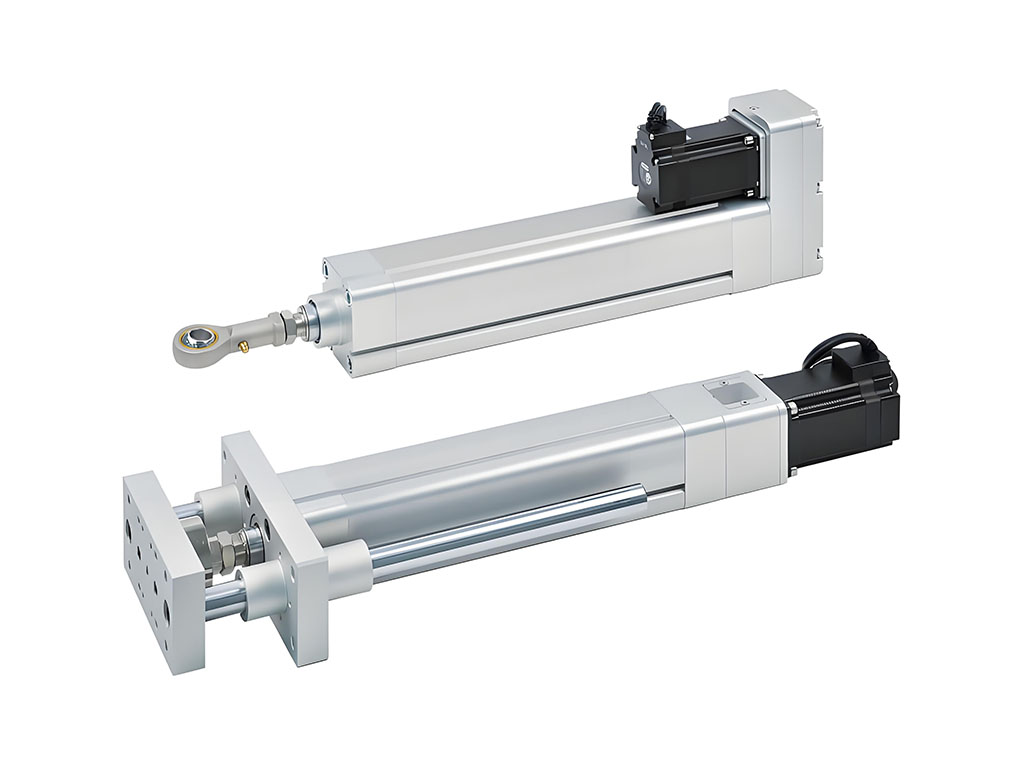

2. Flange Mount (MS2, MS3, MS4 – ISO 15552)

A round or square plate fastens to the end of the cylinder, letting you bolt right to machinery.

- Advantages: Handles big pushes and pulls. Fits into tight spots.

- Downsides: Needs perfect alignment. Any side load can cause trouble.

- Where It Shines: Robots, precise pick-and-place.

3. Threaded Body/End Cap

Here, you screw the cylinder right into your assembly. This option shines where space is tight.

- Advantages: Most compact. Fewer parts.

- Downsides: Only for small loads. Not for heavy lifting.

- Best For: Sensors, small automation parts.

See our range of Electric Cylinders or Mounting Brackets for more custom solutions.

Pivoting Mountings: Give Your Cylinder Freedom to Move

1. Clevis Mount (MS8, MS9 – ISO 15552)

A U-shaped bracket and a pivot pin make the back of the actuator swing like a hinge—often paired with a rod end up front.

- Advantages: Handles misalignment. Allows pivoting arcs and circular motion.

- Downsides: Pins wear if dry. Can get sloppy if not maintained.

- Great For: Opening gates, press brakes, saws.

2. Trunnion Mount (MT4, MT5 – ISO 15552)

Big pins stick out the cylinder’s middle or ends, and those rotate in frame brackets.

- Advantages: Takes big loads. Handles heavy-duty pivoting.

- Downsides: Eats up more space. Needs strong, aligned supports.

- Best Use: Lifting arms, industrial presses.

3. Spherical Rod End / Eye End Mount

A ball-and-socket joint on the rod lets it swing in many directions.

- Advantages: Adjusts to big misalignments. Cuts stress on the rod.

- Downsides: Costs more. Needs regular checks.

- Perfect For: High-precision robots, awkward mount angles.

Curious how these compare in a real system? Here’s a quick table:

| Mount Type | Best For | Watch Out For |

|---|---|---|

| Foot | Simple, in-line moves | Bending, misalignment |

| Flange | Tight spaces, big forces | Needs perfect install |

| Threaded | Tight fits, small loads | Not for heavy work |

| Clevis | Pivoting, arc moves | Pin/bushing wear, play |

| Trunnion | Heavy pivoting, big loads | Needs strong, aligned frame |

| Spherical Rod | Angular errors, complex paths | Higher cost, inspection |

Best Practices and Advanced Considerations

Get mounting right, and your machine hums. Get it wrong, and you face breakdowns. Here’s how to stay on the happy side:

- Always check for perfect alignment, especially with fixed mounts. Tiny angles can stress even big cylinders.

- Use shock absorbers or alignment couplers if loads hit hard or from odd directions.

- If you see any vibration, add vibration damping mounts. This helps control noise and stops fasteners from shaking loose.

- Maintenance matters. Grease the pins. Inspect for play. Replace worn bushings.

- Make sure your machine frame is strong enough for the force. A weak frame will twist or bend over time.

Safety Tip: Turn off, lock out, and double check everything before you work. A little caution prevents the big accidents.

For detailed product specs, see our Servo Motor Actuators and Heavy-Duty Linear Actuators—some of the toughest solutions you can buy.

Picking the Right Mount: Step-by-Step

Use this mini checklist before choosing:

- What’s the motion—straight push or swinging?

- What kind of load—axial, radial, offset?

- How rough is the environment?

- Is space tight or wide open?

- Budget—want the basics or premium?

- Always review specs from the manufacturer.

Example:

You’re building a conveyor pusher. A fixed flange mount lines up perfectly and handles the force well. If you need to open a big metal gate, a rear clevis mount lets the actuator swing with the gate. For lifting a heavy cart that rocks back and forth, a trunnion mount with well-greased pins is tougher than a pack of sled dogs in winter.

Want more hands-on advice? Check out our China Linear Actuator Manufacturer or dive into guides on Standard/Inline Actuators and Rodless Actuators.

Jimi Technology: Your Expert Partner in Linear Motion

We Jimi don’t just sell electric cylinders—we build them right here in our high-tech factory. Our team uses strict quality controls, and our engineers have seen every challenge under the sun. From cleanrooms to steel mills, we’ve helped customers pick the mounting options that last.

We offer:

- Custom Brackets and Mounts: For any challenge, big or small

- Stainless Steel and Corrosion-Resistant Models: For tough environments

- ISO and NEMA Standard Design: Easy to drop into your machine

- Support Every Step of the Way: From design to install and beyond

Check our Electric Cylinder Mounts page to see how we can help bring your automation ideas to life.

Table: Impact and Considerations for Electric Cylinder Mounting Options

| Mounting Option | Typical Use Case | Proper Mount = | Bad Mount = | Trends |

|---|---|---|---|---|

| Fixed Mounts | Packing, slides | Long life, accuracy | Premature wear | 55% use |

| Pivoting Mounts | Gates, lifts, clamps | Less stress, flex | Backlash, noise | 40% use |

| Accessories | Custom jobs | Protects, easy install | Complexity, cost | 70% use |

Conclusion and Call to Action

In automation, the tiniest options make the biggest effects. Selecting the appropriate installing option for your electrical cyndrical tube can indicate the difference between a system that simply functions and one that beams time after time. Get alignment right. Match the mount to your motion and load. Trust in proven designs—and expert support.

If you’re ready to upgrade performance, talk to us at Jimi. We’re not just a China Electric Cylinder Factroy—we’re your motion control partner. See our full Electric Linear Actuators and mounting solutions.

Start strong, mount smart, and make your machines move with power and precision—just the way you imagined.