Introduction: The Foundation of CNC Accuracy

You press a button. The machine whirs to life. You expect perfection—every single time. That’s CNC machining. Computer Numerical Control (CNC) machines cut, mill, and shape metal, plastic, and even wood with astounding precision. But all that accuracy starts before the tool even touches the part. The secret? High-precision linear guides keep the heart of every CNC machine beating true.

Imagine if your CNC axes shuddered, slipped, or wobbled. You’d get rough finishes, tools would break, scrap would pile up. Each axis needs to glide along its path with zero stutter. The real magic happens inside the guides. These simple rails and blocks might not look impressive at first glance, but they supply the rock-solid foundation your entire process depends on. When you crave high-speed, high-volume, flawless output—only precision guides deliver.

Understanding High-Precision Linear Guides

What They Are

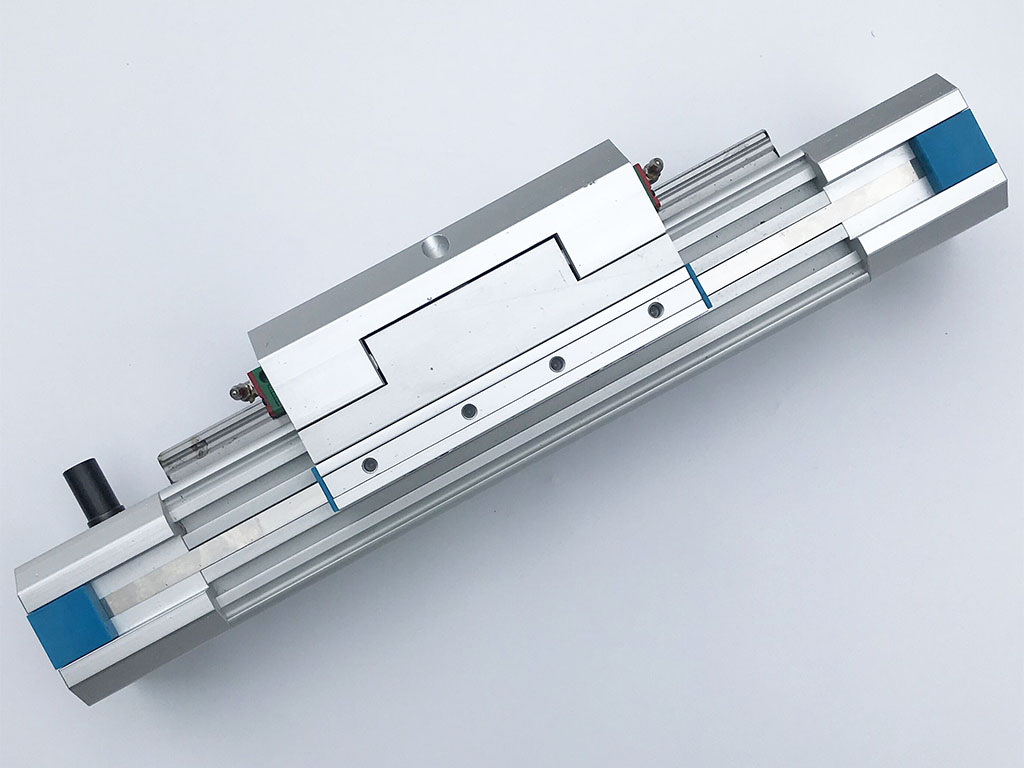

A linear guide is a clever piece of engineering. It’s like a super-smooth train track. The carriage rides along a straight rail, carrying the cutting head with almost zero friction. The best guides use recirculating ball bearings or roller bearings. These let heavy loads move back and forth easily while holding dead-straight accuracy.

Distinguishing “High-Precision”

But not all guides are equal. High-precision linear guides take things to another level:

- They’re ground with tighter tolerances so every part fits perfectly.

- The steel or alloy is top-notch, fighting wear and rust.

- They’re assembled carefully, often with a preload—that means the balls or rollers fit snug, squashing out any slack or “backlash.”

- Each slide runs silky-smooth, no stops or stutters, even at high speeds.

Standard guides might work for a desk drawer. On a CNC? They don’t stand a chance.

Common Types & Characteristics

- Recirculating Ball Guides: The worldwide favorite. Compact, fast, and strong, they shine in everything from milling to lathes.

- Roller Guides: Built for heavy-duty jobs and high loads. Machines that grind, press, or shape giant parts often count on these.

- Crossed Roller Guides: Offer even better stiffness for demanding moves.

- Hydrostatic Guides: Use oil under pressure for zero-contact, ultra-smooth motion. Pricey—but unmatched in accuracy.

What do all these share? Extreme rigidity, dependable accuracy, smooth motion, and loaded-for-bear capacity.

Defining “High-Precision” in Detail

- Accuracy Class: Guides receive grades like P, H, or N. “P” is premier—letting your CNC hold tolerances as tight as ±5 microns. With looser grades, errors stack up.

- Repeatability: A top guide puts the tool tip back in the same spot time and time again. That’s how mass production keeps every part identical.

- Geometric Accuracy: Over long strokes, you need straightness, flatness, and parallelism. Ever seen a part come out cone-shaped instead of cylindrical? That’s what happens when geometric errors creep in.

- Stiffness & Rigidity: The guide must resist bending, squashing, or twisting—even under heavy loads or during fast moves.

- Low Friction & Smooth Motion: Less resistance means less wear, quieter motion, and finer control.

Indispensable Benefits of High-Precision Linear Guides for CNC Performance

Achieving Superior Machining Accuracy

Let’s talk numbers. Swap out “just OK” guides for high-precision ones. You slash positional errors by up to 70%. For example, instead of parts varying by ±15 microns, you hold ±5 microns. That means fewer failed checks and less wasted material.

Ensuring Unrivaled Repeatability

On the shop floor, you don’t want surprises. Consistent repeatability—getting the exact same move, every cycle—is your ticket to perfect batches. High-end guides offer ±0.5-micron returns. Mass production or making spare parts? You can count on it.

Enhancing Surface Finish Quality

Ever run your finger along a smooth, shining part? That flawless finish starts with the guide. With chatter and vibration reduced up to 80%, you get surface roughness down to Ra 0.2µm. The difference is easy to see: you spend less time polishing, and more time getting work done.

Extending Tool Life & Reducing Wear

What’s harder on your wallet than a dull, chipped tool? Frequent tool changes. Smooth, rigid guides mean the cutter stays stable, wears evenly, and lasts longer. Studies show up to 30% longer tool life and less downtime.

Boosting Productivity and Efficiency

If you speed up your feed rate by 25% but still hit specs, you’re making more money every hour. The right guides keep up—even at high speed—skipping all those slowdowns you used to need with basic rails.

Increasing Machine Longevity and Reliability

Everything works together. When your guides resist wear and keep vibration in check, your ball screws, spindles, and motors last longer. Unplanned downtime drops by 20%. Your CNC works, year after year, just like you planned.

| Benefit | Stat/Data Point | Real-World Impact |

|---|---|---|

| Machining Accuracy | Up to 70% cut in positional error | Save material, fewer part rejects |

| Repeatability | ±0.5 µm accuracy return, 50-80% improvement | Uniform part quality in every batch |

| Surface Finish | Ra as low as 0.2µm, 40% less finishing time needed | Less handwork and post-processing costs |

| Tool Life | 15-30% longer tool lifespan | Fewer replacements, lower operating costs |

| Productivity | 10-25% faster machining speeds | More work, greater output per shift |

| Machine Uptime | 20% less unplanned maintenance | Maximize equipment use and meet deadlines |

| Vibration Control | 60-80% drop in vibration at tool tip | Better integrity, less tool breakage, safer operation |

| Total Cost of Ownership | 10-15% lower after 5 years of use | Real ROI—lower hidden costs, more profit |

Critical Applications Leveraging High-Precision Linear Guides

Certain industries can’t compromise on quality.

- Aerospace & Defense: Jets and rockets need parts made to razor-thin tolerances. A single out-of-spec component risks lives.

- Medical Devices: Surgical tools and implants must fit and function flawlessly. Even a tiny error is a big problem.

- Mold & Die Manufacturing: Complex shapes, perfect finishes—mold-makers depend on high-precision motion.

- Optics & Electronics: Micro chips, camera housings, laser components—all require sub-micron control.

- High-Speed & Heavy-Duty Machining Centers: When you cut big parts fast, the linear guide’s ability to stay rigid and smooth at speed is mission-critical.

- Inspection & Metrology: Machines that check part quality—like CMMs—must be more precise than the things they’re measuring. High-precision guides make that possible.

Key Considerations for Selecting and Maintaining High-Precision Linear Guides

Selection Factors

Picking the right guide starts with your application. Here’s what to look at:

- Load (How heavy? Static or dynamic?)

- Required speed (How fast does it need to go?)

- Duty cycle (All day, every day—or just once an hour?)

- Space (Short stroke or long travel?)

- Environment (Cool shop? Dirty foundry? Super-clean lab?)

With these in mind, choose guides that give just enough strength and accuracy for your needs—no more, no less.

The Role of Preload

Think of preload like lacing up a running shoe tight. It removes slop, firms up the fit. Preloading takes out the internal play in guides. The result? Higher stiffness, better accuracy, and near-zero backlash. You cut vibration and make the machine feel more “locked in”—like a fresh pair of hiking boots.

Proper Installation

Precision only matters if you use it right. The foundation must be square, rails absolutely straight, bolts torqued just so. Even a tiny twist during install can undo all that expensive manufacturing work.

Effective Lubrication

Ever hear a door squeak? Now imagine that squeak inside your million-dollar CNC machine. Correct lubrication means the slides don’t stick, jam, or wear out. The oil or grease you choose matters—so do regular checks.

Environmental Protection

Guides hate dirt, chips, and coolant splash. Seals, wipers, and bellows keep out the bad stuff. That way the bearings keep rolling for years, not months.

For practical examples and application-specific guidance, visit Linear Guides & Rails. If you’re considering other motion options for your next project, look at our advanced Ball Screw Actuators, or explore Industrial Automation Actuators for complete automation solutions.

The Jimi Technology Advantage: Engineering with Confidence

At Jimi Technology, we live and breathe precision. Our experts design, build, and test every linear guide to world-class standards. We use only the best raw materials and advanced grinding. Every production run checks out against ISO and DIN standards for ultimate reliability. Whether it’s a custom machine or a standard model, we know the nuts and bolts because we make them—right down to the last micron.

Clients trust us because we:

- Provide free consultation and technical support

- Offer global delivery and supply chain reliability

- Back every product with proven performance data

We believe in honest engineering. Buy a Jimi linear guide, and you join a family that puts your uptime first. Want to see more? Compare our Servo Linear Actuator Factory expertise or investigate our line of Electric Linear Actuators for complex, modern automation needs.

Conclusion: Invest in Precision, Win the Future

Don’t let hidden errors rob your bottom line. Modern CNC machining success comes from one core: high-precision linear guides. They cut errors, save money, and make your machines last longer. They safeguard every cut, every process, and every order you fill. They’re not a “nice-to-have”—they’re your ticket to competitive advantage.

If you want top-tier accuracy, unrivaled repeatability, and the lowest long-term costs, don’t leave your choice of guides to chance. Team up with experts. That’s where Jimi comes in. We’ll help you pick the right rail, keep it running for years, and drive your next wave of manufacturing success.

Ready to start? Reach out to Jimi’s technical team today and see how our high-precision linear guides can lift your CNC—and your whole operation—to new heights.

For solutions that empower productivity and reliability, also check out our Industrial Linear Actuators or discover the benefits of Heavy-Duty Linear Actuators in large-scale applications. At Jimi, precision isn’t just a promise. It’s built into every move your CNC makes.