If you want to know more vedioes about linear guides, you can go to visit our Youtube Chanel.

Introduction: Enabling the Precision Revolution

Ever before wonder what keeps contemporary factories running so efficiently? Image an auto production line, or a robot arm grabbing little equipments, or a laboratory tool gliding with identify precision. Behind every bit of that movement, there’s a simple hero: the linear guide. It’s not showy. It won’t grab headlines. Yet take it away, and the whole game changes. If you build or automate anything, from packaging a snack to printing circuit boards the size of your fingernail, you rely on these silent champions. Linear guides bring speed, precision, and reliability into our high-tech world.

What Are Linear Guides? A Foundation of Motion

Basic Principles of Linear Motion

At its core, a linear guide is a track. Its job? Keep something relapsing and forth in a straight line, with almost no friction. It’s like ice skating, yet without the slip-ups. Sometimes, direct overviews aid transform spinning pressure (think: an electric motor transforming) right into a straight push or pull.

Key Types and Their Applications

Not all guides are born equal. Here’s what you’ll find in the wild:

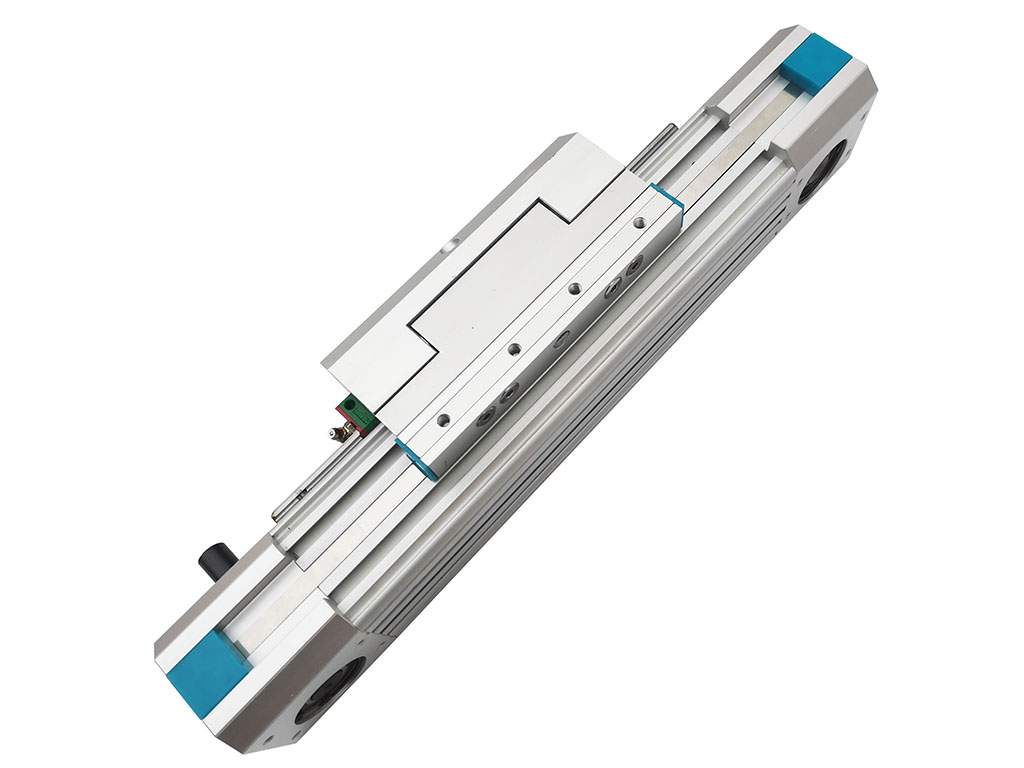

- Profile Rail Guides (Ball/Roller Type): These use rows of tiny balls or rollers. Picture a drawer on super-smooth tracks; only, these are crazy precise. Industrial CNC machines, laser cutters, and machine tools love them for their high load and unwavering accuracy.

- Round Shaft Guides: Think simpler, lighter, and often cheaper. They shine in places where huge precision isn’t needed—light automation equipment or simple pick-and-place robots, for example.

- Plain Bearing Guides: Dusty, dirty, or super slow? These thrive where others would grind to a halt thanks to their simple design that handles rough conditions.

- Heavy-duty and Miniature Variants: Big factory press? There’s a guide for that. Tiny medical device? There’s one for that too.

You’ll see them all over, from the massive to the minuscule—each type picked for a specific job.

The Indispensable Contributions: Why Linear Guides Are Core

Unparalleled Precision and Accuracy

Let’s face it—guesswork doesn’t cut it in modern manufacturing. You want car parts that fit like a glove, robots that never miss a beat, and circuit boards with gold wires thinner than a hair. Linear guides can deliver positioning that’s accurate to within a micron or less. In semiconductor work, for instance, they’re used to create chips that power your phones and smart cars. Miss by even a tiny bit, and the whole product could fail.

High Speed and Efficiency

Factories run on speed. The faster you can move, the more you make. Install high-speed guides and suddenly a process that took 60 seconds now takes 50. That’s not just faster—it can mean 7% more cars off the line each day, like in one recent automotive case study. In a race where seconds mean profits, guides set the pace.

Handling Heavy Loads and Maintaining Rigidity

Some jobs require muscle. Ever seen a giant 3D printer stacking up layers the size of refrigerators? Heavy-duty linear guides hold hundreds of pounds and refuse to bend out of line. They handle dynamic loads over 100 kN while staying straight and true. That strength is essential for tasks like accuracy steel reducing or large-scale product handling.

Sturdiness, Reliability, and Reduced Maintenance

Broken machines cost money. That’s why only the tough survive on factory floors. Secured, corrosion-resistant guides slash downtime: one medical device business saw upkeep drops by 40% after switching. Less breakdowns mean smoother manufacturing and happier consumers.

Flexibility and Adaptability

No two work are alike– and neither are the settings. Whether you work in a cleanroom making microchips or on an oily car production line, there’s a guide that fits. Some resist dust, some work in high heat, and others tackle chemicals. You can even build customizable linear guide solutions for tricky problems. Need to move in three directions at once? No problem—multi-axis systems are easy to set up.

Linear Guides in Action: Industry-Specific Impact

Manufacturing & Machine Tools

CNC Machining, milling, and lathes all depend on guides to hit tight tolerances. When a laser needs to cut or weld without drifting a millimeter, the guide keeps things steady. Miss by too much and the whole batch is wasted. No guide, no quality.

Robotics & Automation

Robots have to move fast. Gantry systems and robot arms fly from one edge to one more without trembling, thanks to direct movement rails. Pick-and-place robotics take care of recurring tasks in factories. They never burn out, constantly hit the exact same area, each time– thanks once again to the reliability of direct guides.

Curious about the tech inside the robots? Check out our Industrial Linear Actuators to discover the backbone of automated movements.

Medical & Life Sciences

You trust the machines that analyze your blood to be precise. That’s where guides shine. From sample handling in labs to surgical robots in the operating room, guides deliver the kind of steady, exact motion doctors rely on. It’s not about speed here—it’s all about trust and repeatability.

Semiconductor Manufacturing

If you want small, this is the world of the ultra-tiny. Guides with ±0.5 µm accuracy help position wafers in chip fabs. Try building the next smartphone chip without them. Now imagine the error if you had to do this by hand—it’s not possible.

Packaging & Material Handling

Endless boxes, bottles, and bags speed down conveyor lines. High-speed sorting, filling, and stacking all depend on guides to run around the clock. They help get your products where they need to go—no lost time, no mess.

For more, see our expert line of Electric Linear Actuators for packaging and material handling.

Powering Industry 4.0 and Beyond: The Future of Motion

Integration with Smart Systems

Industry 4.0 is more than a buzzword. Think smart factories where machines talk to each other, predict when they’ll need cleaning, and optimize their own routine. Modern guides plug into these digital webs. Sensors built into guides deliver real-time performance data. They power predictive maintenance, so you fix parts before they break.

If you’re curious, our Actuators with Position Feedback make smart integration effortless.

Miniaturization and Customization Trends

Factories shrink, but demands grow. Smaller devices, smarter robots, leaner lines. Miniature guides keep up. Tiny linear rails inside 3D printers or lab gear work as well as their bigger brothers, because precision never scales down.

Need something tailor-fit? Our DIY Projects & Robotics Linear Actuators show how flexible, hands-on solutions get built.

Sustainability and Energy Efficiency

Green matters more than ever. Guides help by cutting friction, which means 20% less energy used in some applications. Factor in longer life and less waste, and you see how they fit into a more sustainable, future-focused industry.

Data Table: The Impact of Linear Guides

| Benefit | Example | Result |

|---|---|---|

| Precision in Semiconductors | Sub-micron accuracy in wafer handling | Advances in microprocessors, innovation |

| Throughput in Auto Plants | 15% faster welding with high-speed guides | 7% more vehicles built per day |

| Reliability in Medical Devices | Sealed guides cut downtime by 40% | Fewer interruptions, higher efficiency |

| Load Handling in Machine Tools | 100 kN support with <10 µm deflection | High-precision, heavy part machining |

| Energy Savings in Automation | Optimized lubrication, low friction | Up to 20% energy savings |

| Flexibility for Robotics | 6-axis robots, wider, more precise reach | Task diversity, fast adoption of automation |

| Advanced 3D Printing | Heavy-duty guides for large-scale additive builds | Big, complex parts fabricated accurately |

Why Jimi is Your Trusted Linear Motion Partner

We at Jimi Technology don’t think of ourselves as just another supplier. We design and build precision engineering solutions for every challenge you face. Our portfolio includes linear motion systems, TV lifts, automation components, and complete solutions for both simple and advanced needs. We never cut corners on quality—every guide, actuator, and part meets top industry standards for durability, accuracy, and reliability.

We aren’t just about products, either. Need help picking the best ball screw linear guide for your factory? Looking to customize a motion stage for harsh environments? Our experts walk you through, every step of the way.

Want to see our range for yourself? Explore our Linear Guides & Rails or browse China Electric Cylinder Factory for every form of linear movement your project needs.

Internal Links for Learning and Innovation

- Discover precision components: Linear Guides & Rails

- Rugged off-the-shelf solutions: Heavy-Duty Linear Actuators

- Smart control for next-gen factories: Actuators with Position Feedback

- Support for all your applications: China Linear Actuator Manufacturer

- DIY automation and robotics: DIY Projects & Robotics Linear Actuators

We also provide specialized support on design and installation—so your line runs with the speed, accuracy, and reliability only true experts deliver.

Conclusion: The Unsung Heroes of Modern Progress

Linear guides sit at the heart of every thriving, modern industry. They give you micron-level accuracy when stakes are high, sheer muscle when jobs get heavy, and smooth, quiet motion no matter the challenge. If you demand more speed, less breakdowns, and less energy waste, the right overview adjustments everything.

As factories approach Industry 4.0, clever robotics, and progressed production, direct guides do not simply maintain– they blaze a trail. Want your procedure running like clockwork?

Our team at Jimi is here to help. From customizable solutions to expert advice, we turn complexity into everyday ease. Don’t let friction—for your machines or your ambitions—hold you back.

Contact us today or browse our expert solutions for the perfect fit. Upgrade your motion, boost your success. Let’s build something great—one smooth, accurate move at a time.