Hello! Want to Move Something Just Right?

Let me ask you a simple question. Have you ever pushed a button and watched your TV rise, a drawer open, or a robot arm reach out—almost like magic? You want this movement to be smooth, safe, and right every time, don’t you?

I’m here to show you how stepper linear actuators make these amazing things happen. At Jimi (Jimi Technology Co., Ltd.), I help people—just like you—move stuff easily and precisely. With our products, you can tilt, push, pull, or lift just about anything with a tap.

What is a Stepper Linear Actuator?

A stepper linear actuator is a smart machine part. It uses electricity to move in a straight line. Imagine a tiny motor inside. It turns, then a lead screw or ball screw changes that turning into a straight move. It’s like twisting a jar lid and watching the top move up.

These are not just simple motors. The core idea is simple and smart: you want linear motion control stepper magic for precision linear actuator stepper tasks.

How Stepper Linear Actuators Work—Simple as Counting Steps

Here’s a fun way to think about it. Take small steps forward, one at a time, not running, not guessing. Each stepper motor makes tons of tiny, counted moves (called microstepping or full step) using an integrated stepper linear actuator and a lead screw stepper actuator.

When you press a button, control signals go to the stepper motor driver linear actuator, and then the actuator moves. Some use encoder feedback for extra accuracy. Others work with open-loop control, making them easy to set up.

Chart: How Motion Works

| Part | What It Does |

|---|---|

| Stepper Motor | Turns bit by bit (steps—not spinning wild!) |

| Lead Screw / Ball Screw | Changes turning into moving in a line |

| Encoder | Measures the position (closed-loop) |

| Controller | Tells the actuator how far to go and when |

| Nut / Ball Nut | Makes moving parts glide smooth and quiet |

Types of Stepper Linear Actuators

You want the best type for your job, right? Here are the four main kinds:

- Captive Stepper Actuator:

The screw is fixed, and the nut moves inside a tube. Great for compact linear actuator stepper jobs.

- Non-Captive Stepper Actuator:

The nut stays inside, and the screw goes in and out. Use it where you want to guide movement from outside.

- External Nut Stepper Actuator:

The motor spins the screw, and an outside nut slides along. Perfect when you need to change the setup or expand.

- Integrated Design Stepper Actuator:

Motor and screw built together. Super easy to mount; saves space.

Need to see options? Check out China Linear Actuator Manufacturer to find every actuator type you could imagine.

Why Pick a Stepper Linear Actuator?

Let’s look at the big wins.

- High Precision & Repeatability

You want it to hit the right spot. Every time. These are known for exact positioning, with repeatable steps—great for robots, lab gear, or making sure every Z-axis in a 3D printer linear actuator puts down layers just right.

- Excellent Holding Torque

Steppers hold the spot even with no extra power—much safer and cheaper than some motors.

- Affordable

I give you the best for less. In fact, stepper linear actuator price is often 20-50% lower than servo-motor systems—wow!

- Simple to Control

Just tell it what position you want, and it goes—no fuss with fancy feedback.

- Built Tough

Our durable actuators offer long life—up to 100 million cycles. You want them to last, right?

Limits You Must Know

Sure, everything has a downside. Here’s what you need to think about:

- Speed:

Not as fast as servo linear actuators, but great for accuracy.

- Force:

Don’t use them for big heavy lifting (use hydraulic linear actuators for that).

- Heat:

Running for hours? Size it right to keep cool.

- Resonance:

Sometimes it shakes or vibrates at certain speeds.

- Backlash:

That’s a little wiggle or play in movement, but I fix this with anti-backlash nut stepper designs.

Want tough jobs done? See our Heavy-Duty Linear Actuators for more force.

Where Will You See Stepper Linear Actuators?

You’ll spot these wonders everywhere:

- Medical Devices & Lab Gear:

Like syringe pumps, fluid dispensing, microscope focusing—all need tight control.

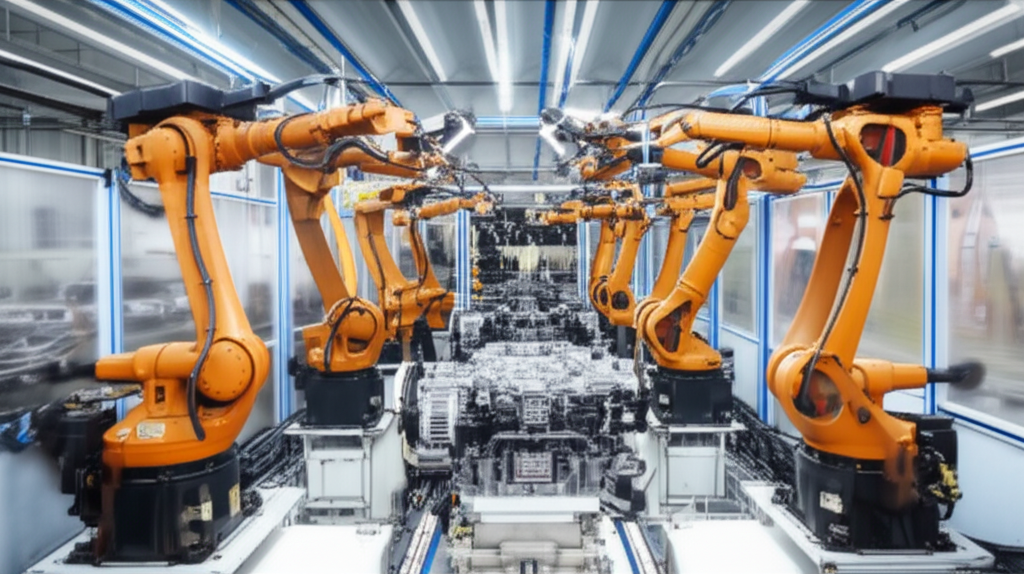

- Automation and Robotics:

Used in pick-and-place, sorting, and linear motion control stepper assembly.

- Optics & Cameras:

Focus a lens, align sensors—it makes images sharp!

- 3D Printing:

Lays down each layer at the correct height for the perfect build.

- Semiconductors, Manufacturing:

Moves wafers or opens tiny valves with perfect accuracy.

Need an actuator for lab or medicine? Try our Light-Duty / Miniature Actuators for fine movement.

How to Choose The Best Stepper Linear Actuator For You

Pick the right tool. Here’s what to check:

- Stroke Length:

How far do you need it to go?

- Thrust Force:

How much do you need to push or lift?

- Linear Speed:

Fast or slow—is your job a quick move or a careful slide?

- Accuracy/Resolution:

Super tight or good enough?

- Repeatability:

Does it come back to the same spot every time?

- Duty Cycle:

Will it run a little or a lot?

- Mounting & Environment:

Where will it work? Hot, cold, wet?

- Control Needs:

Do you want simple On/Off or precise encoder feedback?

- Cost vs. Power Trade-offs:

You want value, but you need performance.

Table: Quick Sizing Guide

| Factor | Range/Check |

|---|---|

| Stroke Length | 10mm – 1 meter (or more) |

| Thrust Force | 5N – 500N+ |

| Speed | 1mm/s – 200mm/s |

| Precision | 0.001mm – 0.1mm (1-100 microns) |

| Repeatability | +/- 1 – 10 microns |

Need help sizing? Check out Electric Linear Actuators for ideas and tools.

Explore the vital performance metrics, advantages, and market dynamics shaping the world of stepper linear actuators in modern engineering.

0.001 mm to 0.1 mm

(1 to 100 microns)5 N to 500 N+

(1 to 100+ lbs)1 mm/s to 200 mm/s

(0.04 to 8 in/s)+/- 1 to 10 microns

(Consistent return to position)1 Million to 100 Million+

(Dependent on load & maintenance)40-60 dB

(Relatively low)-20°C to +50°C

(Standard industrial range)Projected CAGR through 2028-2030, driven by increasing automation, medical device demand, and industrial IoT.

20-50% Lower Initial Cost

compared to comparable servo-motor systems.Offers an excellent balance of performance and price for suitable applications.

High Precision & Repeatability

Excellent Holding Torque

Cost-Effectiveness

Compact Footprint

Energy Efficient

Stepper vs. Servo, Pneumatic, Hydraulic—Who Wins?

- Stepper Linear Actuator vs. Servo:

Steppers hold steady better, cost less, and are easier to control. Servos win on super speed and power.

- Stepper vs. Pneumatic/Hydraulic:

Steppers give clean electric motion—no messy pipes or leaking fluid—and are programmable, great for small spaces.

Need high power in a clean design? See Servo Linear Actuator Factory for more.

What’s New—Innovation Never Stops!

Every year, these actuators get:

- Smaller and Lighter

Now you can fit them in tighter spots.

- Smarter

Integrated electronics mean easier setup.

- Tougher

New materials boost lifetime and efficiency.

- More Feedback

Advanced sensors track every move.

Want smart upgrades? See how we deliver innovation at China Electric Cylinder Factory.

Why Trust Jimi?—Your Automation Experts

At Jimi, I don’t just sell parts. I help you solve problems. My expert engineers, strict quality control, and fast support mean you get what you need—every time.

References:

- ISO Quality Certified

- 100+ Million Cycles Tested

- Expert Support, Fast Delivery

Let’s Move—Contact Us Now!

Ready to make your project smooth, smart, and easy? Choose Jimi stepper linear actuators. I guide you step by step, from plan to installation. Let’s work together and build a future where everything moves just right.

See our Stepper Motor Actuators, Ball Screw Actuators, and Lead Screw / Acme Screw Actuators for more solutions.

Contact me today—together we make every move count!