Recognizing the Fundamentals: What Are Electric Cylinders?

Photo this: devices in a factory press, pull, lift, and press heavy loads with simply the faucet of a display or journalism of a switch. What makes that effective, smooth, and peaceful step occur? That’s the task of electrical cylinders.

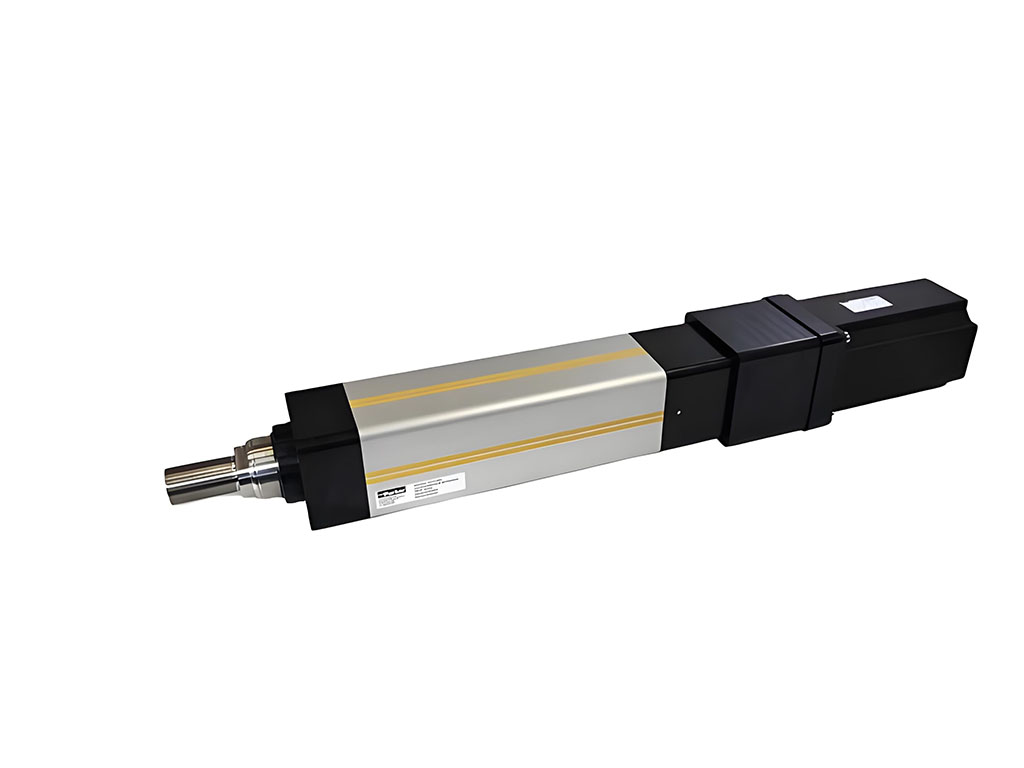

Electric cylinders are devices that change the turning motion of a motor into a straight push or pull. Each one comes with three main parts:

- A motor (the power source)

- A lead screw or ball screw (the part that spins and moves)

- A housing (to hold it all together)

Why do more engineers and factory owners pick electric cylinders over hydraulic or pneumatic ones these days? Here’s why:

- Clean operation – No oil leaks or air hoses.

- Better energy use – They only use power when moving.

- Accurate control – You tell it what to do. It listens.

- Easy upkeep – Less mess, fewer moving pieces.

Ready to dig deeper? Let’s break down two main types: Standard Electric Cylinders and Servo Electric Cylinders.

Deep Dive into Standard Electric Cylinders

First up: the workhorses of simple automation.

Standard electric cylinders often use either:

- Stepper motors (they move in set “steps”)

- DC motors (they spin at a steady speed)

Their control is usually “open-loop.” That’s a fancy term for: you tell it to move, it moves, and it doesn’t check if it made it to the perfect spot. Simple, right? DC motors also come in simple “closed-loop” forms for better speed control, but they’re not as smart as full servo systems.

Key Points:

- Easy to set up

- Lower price tag

- Good for basic push-pull or lift tasks

- Work best when you don’t need tiny, precise moves

- Limited control – mostly fixed speed, less exact stopping points

Applications: Think of opening and closing gates, pressing a button, moving a part from point A to point B. Not rocket science – just plain reliable.

Find out more about these options at our Standard/Inline Actuators and Electric Cylinders pages.

Exploring Servo Electric Cylinders

Now, what if you need to move something with pinpoint accuracy? Or, you want to speed up, slow down, and change direction on the fly?

Step up to the high-tech world of servo electric cylinders.

Servo cylinders use special servo motors and a “closed-loop” system. Here’s the magic—each cylinder has an encoder or resolver that keeps track of exactly where it is, right down to a tiny sliver of a millimeter. The servo drive checks this info and makes micro-adjustments in real time.

Main Features:

- Super precise moves (think nearly perfect repeatability: +/- 0.01 mm)

- Quick, smooth starts and stops

- Strong force in a small package

- Programmable patterns and complex moves

- Sync up with other axes or robots

- Higher starting cost and setup time

Common uses: Robotics arms, testing machines, automatic packagers, places where “good enough” just won’t cut it.

Find more info at our Servo Motor Actuators and Ball Screw Actuators guides.

Head-to-Head Comparison: Servo vs. Standard Electric Cylinders

Let’s pit these two giants against each other. Which one fits your project? See the key differences at a glance.

| Feature | Servo Electric Cylinder | Standard Electric Cylinder |

|---|---|---|

| Precision | Highest (+/- 0.01 mm) | Moderate (+/- 0.05–0.1 mm) |

| Repeatability | Excellent (closed-loop, real-time feedback) | Good for non-critical tasks |

| Speed | High, dynamic, and variable | Fixed or limited |

| Force Output | High for size (holds force at speed) | Lower, drops at high speed |

| Control | Complex, programmable, real-time correction | Simple start/stop, move/return |

| Cost | Higher upfront, more cost-effective over long life | Lower upfront, higher TCO for some uses |

| Energy Use | Very efficient, adjusts to load | Less optimized |

| Noise | Quiet, smooth | Can be noisy (especially stepper) |

| Maintenance | Ball screw (long life), needs some upkeep | Lead screw (shorter life) |

| Installation | More complex (needs tuning, wiring feedback) | Simple setup |

Real-World Data:

- Cost: Servo cylinders may cost 2 to 5 times more upfront (source: Bosch Rexroth).

- Efficiency: Servo cylinders use up to 30% less energy than pneumatics over time (source: Parker Hannifin).

- Longevity: Ball screws in servos last up to 100 million cycles vs. 20 million for lead screws (source: NSK Linear).

This means: for some jobs, you get what you pay for.

When to Choose Which: Application-Specific Guidance

You wish to select the best tool for the work, right? In some cases, the basic answer is best. Other times, you need all the bells and whistles.

Choose Standard Electric Cylinders when:

- The job is simple: just move, no need to stop at an exact spot

- The load isn’t super heavy

- Budget is tight

- Automation tasks: basic gate openers, light-duty presses, panel lifters

Check out Medium-Duty Linear Actuators or Stepper Motor Actuators for ideas.

Choose Servo Electric Cylinders when:

- You need ultra-precise moves

- The task calls for high speeds or fast changes

- You’re controlling a robot, a multi-axis table, or test rigs

- The system runs 24/7 and downtime is not an option

- You want to record feedback or add remote monitoring

Get inspired by our Industrial Linear Actuators or Industrial Automation Actuators.

Installation, Integration, and Longevity Considerations

No one likes a project that gets held up by messy installs. The good news: standard cylinders set up quickly. Mount it, wire the power, set the limit switches, and you’re ready.

Servo cylinders need a bit more TLC. You’ll:

- Align the unit perfectly to avoid binding

- Connect feedback wires and encoders

- Program the controller or PLC for custom moves

Lifespan comes down to three factors:

- Obligation cycle (exactly how hard it works).

- Upkeep (mostly keeping points tidy and lubed).

- Environment (clean room or dirty factory floor?)

Tip: Ball screw designs (typical in servo systems) can last five times longer than a simple lead screw, given proper care.

Future Trends in Electric Cylinder Technology

Tomorrow’s innovations are here today at Jimi. We see three big trends:

- Smaller, stronger actuators for tight spaces and tough loads

- Smart integration with IoT sensors – get alerts before failures

- Easier programming software so anyone can set up a move

Want to explore more? See how we push electric actuators into the future at our Servo Linear Actuator Factory.

FAQ

What is the main difference between a servo motor and a standard motor in an electric cylinder?

A servo motor uses closed-loop feedback for spot-on moves, while a standard motor just follows commands and does not check exact position.

When should I choose a servo electric cylinder over a standard one?

Pick a servo when you need really accurate moves, fast changes, or have to control many axes at the same time.

Are servo electric cylinders more expensive than standard ones?

They cost more to buy but may save you money down the road through less downtime, lower energy bills, and fewer replacements.

What are the accuracy differences in between servo and basic electric cyndrical tubes?

Servos hit +/- 0.01 mm repeatability; standards remain in the +/- 0.05– 0.1 mm array.

Do servo cyndrical tubes need more complex programs?

Yes. Yet the payoff is much more control and smarter, more secure automation.

What is the common life expectancy of an electric cylinder?

Servos with ball screws: up to 100 million cycles. Lead screw kinds: up to 20 million cycles.

What are the advantages of using servo electric cylinders?

Top-notch accuracy, fast moves, high force, quieter operation, and smart feedback.

Do servo cylinders require more complex programming?

Yes. But the payoff is more control and smarter, safer automation.

What is the typical lifespan of an electric cylinder?

Servos with ball screws: up to 100 million cycles. Lead screw types: up to 20 million cycles.

Just how do electric cyndrical tubes contrast to hydraulic or pneumatically-driven cyndrical tubes in regards to control?

Electrics are cleaner, quieter, and provide you exact steps every single time.

Conclusion & Next Steps

When you’re choosing the ideal electrical cylinder, ask on your own: Do I need straightforward relocations, or do I need accuracy? Is the price up front more important, or do I need integrity and efficiency over the long run?

At Jimi Technology, we do not simply offer electric cyndrical tubes– we aid you resolve troubles. Our team brings years of market knowledge, top-quality components, and full assistance whether you’re new to automation or developing the next large point. Depend on us for expert guidance, confirmed resilience, and complete services from beginning to end.

Ready for answers that fit your project? Check out our China Electric Cylinder Factory, get a quote for your needs, or contact us for personalized guidance. With Jimi, you turn ideas into motion—every time, with confidence.