Imagine walking into a modern poultry house. Instead of the noise and hustle of busy workers, you hear the steady hum of machines. Chickens, healthy and calm, have fresh food and clean water. The air smells fresh. Eggs roll gently onto a conveyor without a crack. That’s the silent power of servo cylinders at work.

Understanding Servo Cylinders: The Precision Actuators for Modern Farms

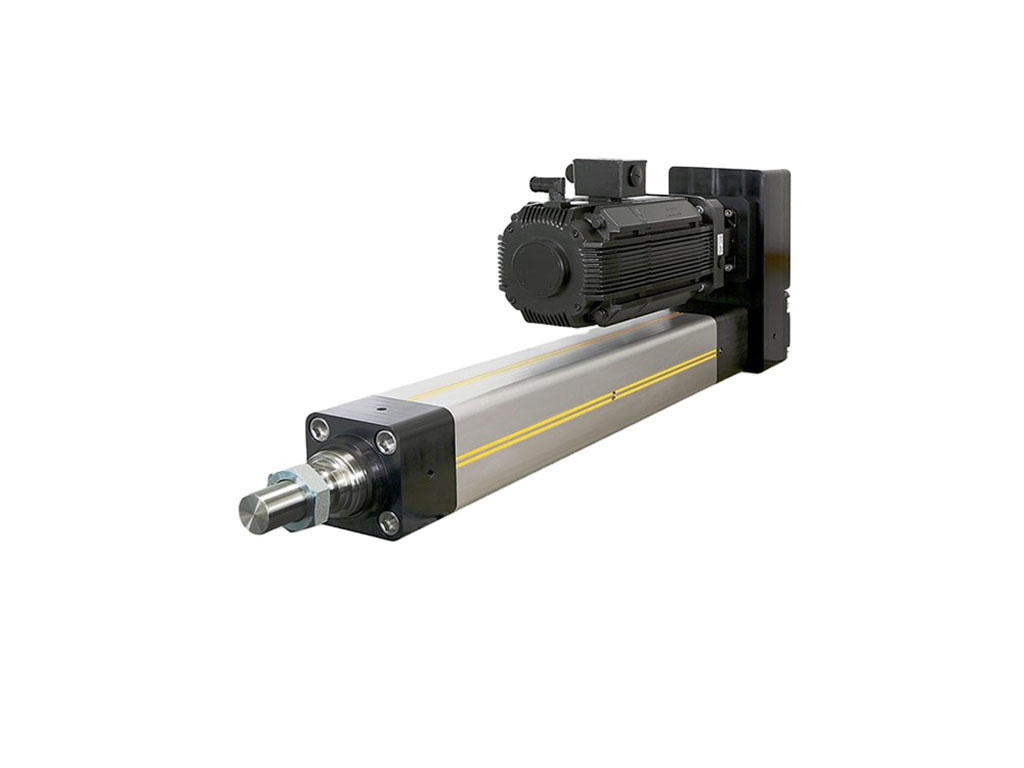

Servo cylinders sound fancy, but their job is simple. They help move things in a straight line at just the right speed and place. Think of a strong but gentle helping hand that you can control with a button. At the core, they use electricity to turn a small motor. This motor spins a special screw, which pushes a rod back and forth. There’s a sensor inside called an encoder. It checks – thousands of times a second – that the rod is in the right place.

Key parts of a servo cylinder:

- Servo motor

- Screw (ballscrew or roller screw)

- Rod (moves things up, down, back, or forth)

- Encoder (the “brain” for feedback)

- Guide rail (keeps everything straight)

This feedback loop gives you amazing control. Unlike simple actuators, servo cylinders know and hold their position exactly, every time. Whether it’s lifting, pushing, or pulling, they get it right.

For farm tasks that repeat all day or need delicate care, this matters. With Servo Linear Actuator Factory expertise, Jimi Technology delivers this precision time after time.

The Imperative of Automation in Today’s Poultry Industry

Running a poultry farm used to be simple. Feed the birds in the morning. Clean the house after lunch. Collect eggs by hand. But today’s farms face bigger flocks, less labor, and higher costs. You want your birds to eat just the right mix. They need comfort—heat in winter, cool in summer, fresh air always. You must keep them healthy and safe, with less human contact to stop disease.

This is where automation comes in. Machines don’t get tired. They don’t call in sick or make mistakes. Servo cylinders, connected to smart controls, can:

- Save labor and costs

- Cut mistakes and waste

- Keep a steady, ideal living space for the birds

And let’s face it—shoppers care about how food is grown. Automated systems, like those run by Jimi’s servo cylinders, help farms deliver eggs and meat that are more ethical, sustainable, and traceable.

Key Applications of Servo Cylinders in Automated Poultry Operations

Precision Feeding and Watering Systems

Birds thrive on routine. A Electric Cylinder with servo control can give feed and water down to the last gram or drop, right on time. No spills or shortage. This means healthier, uniform flocks and less money wasted. Studies show farms with servo feeders cut waste by up to 15%, and improve feed conversion by 3%.

Servo cylinders can also deliver medicines and vitamins exactly—keeping the birds healthy, and you in control.

Automated Ventilation and Climate Control

Birds are sensitive to warmth, cool, and air quality. Servo cyndrical tubes open and close vents, change drapes, and control followers efficiently. If it gets warm, they let in cool air. Humid? The system reacts right away. This keeps the flock comfy and stops illnesses before they start. Plus, you use less power, since every move is just enough—not too much.

Egg Collection, Sorting, and Packaging

Eggs are valuable but fragile. Servo-driven belts pick them up softly, sort by size and weight, and move them fast but gently. This means fewer cracks—more profits for you. In fact, one medium-sized farm saved $25,000 in just two years by switching to smart servo egg collectors.

Manure Removal and Waste Management

Nobody enjoys this job, but machines don’t mind. Servo-powered scrapers clear manure out at set times, keep the floors clean, and lower ammonia in the air. The result: birds and workers breathe easier, and the risk of disease drops.

Broiler and Layer Processing Automation

Cutting, sorting, and handling chickens in a busy processing line? Servo cylinders handle each bird the same way, every time. This keeps the product safe and quality high. It’s also much more humane.

Unpacking the Benefits: Why Servo Cylinders Lead the Way in Poultry Automation

Unmatched Precision and Repeatability

Let’s break it down. Servo cylinders use a feedback “brain” to check their position again and again. That means you can hit the same spot—up to 0.01mm—hundreds of times a day. This is vital for tasks like dosing medicine or lifting eggs.

Improved Energy Efficiency and Reduced Operating Costs

Hydraulics need pumps running all the time. Pneumatics make use of huge air compressors. Servo cylinders utilize power just when they move, saving up to 80% on energy, according to Parker Hannifin research study.

Improved Reliability and Longevity

With fewer moving parts, servo cylinders don’t leak or wear out fast. Top models from Jimi run for over 100 million cycles. They keep going, even in dust and dirt.

Greater Flexibility and Adaptability

Need to change tasks or flock sizes? Reprogram the controller. Add a sensor or new setting? No problem. Servo systems talk to your main farm computer (PLC or HMI) and adapt as you need.

Contribution to Animal Welfare and Biosecurity

When fans, feeders, and collectors run like clockwork, birds get what they need, stress less, and stay healthy. Machines also mean less people in the house, so germs and diseases stay out. Research notes up to 70% less disease risk where hands-off automation is used.

Servo Cylinders vs. Traditional Actuators: A Comparative Analysis

Let’s compare choices:

| Feature | Servo Cylinders | Hydraulic Cylinders | Pneumatic Cylinders |

|---|---|---|---|

| Precision | Very high (+/- 0.01mm) | Medium | Low to medium |

| Energy Use | On demand, efficient | High, needs pump | High, needs compressor |

| Maintenance | Low | High (leaks, fluids) | Medium (air leaks, filters) |

| Cleanliness | Very clean (no fluids) | Can leak oil | Moisture/oil in air |

| Flexibility | Reprogrammable | Harder to adjust | Limited fine tuning |

| Initial Cost | Highest | Medium | Lowest |

| Total Cost (5 years) | Often lowest | High | Medium |

Servo cylinders cost more at first, but you save in energy, less breakdowns, and lower waste. They also let you run a cleaner, greener farm.

Implementing and Integrating Servo Cylinder Systems in Your Farm

Ready to upgrade? Here’s what to check:

- Force and Speed: Pick a servo cylinder that matches your job—big tasks may need a Heavy-Duty Linear Actuator.

- Stroke Length: That’s how far the rod needs to get to.

- Defense: Choose IP-rated, dustproof or water resistant versions if your house splashes or unclean.

- Controls: Make certain your servo talks with your PLC or HMI system.

- Sensors: Want feedback? Add Actuators with Position Feedback to track every movement.

- Installation: Work with pros like Jimi who know poultry and automation.

Keeping servo cylinders running is easy—just a little cleaning and a checkup now and then. No greasy hands, no spills on the floor.

Future Trends and Challenges in Poultry Automation

Smart farms are the future. Imagine servo cylinders that can “think” using AI or machine learning—predicting when things break, or adjusting feed if birds seem stressed. With data from the Internet of Things (IoT), managers watch every flock live and solve problems fast.

Upfront costs can be scary, but remember: savings stack up. Cleaner, faster, and more efficient farms also look good to banks and investors. Jimi leads the way, helping clients every step from planning to install to service.

FAQ

How do servo cyndrical tubes boost effectiveness in automated chicken ranches?

Servo cyndrical tubes give exact control, decrease waste, and cut labor expenses.

What are the main applications of servo cyndrical tubes in automated chicken residences?

Feeding, watering, ventilation, egg handling, manure removal, bird processing—almost everywhere you need smart movement.

Are servo cylinders more energy-efficient than hydraulic or pneumatic systems in agriculture?

Yes. They save up to 80% electricity since they only use power when they work.

What kind of precision can servo cylinders achieve in poultry feeding systems?

They can hit the same mark with a margin as tight as 0.01mm—key for accurate feed and medicine.

Just how do servo cylinders add to far better pet welfare in automated ranches?

They develop a steady, healthy atmosphere, manage birds carefully, and minimize illness danger.

What is the typical lifespan and maintenance requirement for servo cylinders in farm environments?

Top models easily top 100 million cycles, with only basic cleaning and checks needed.

Can servo cylinders be retrofitted into existing poultry farm automation setups?

Yes. Many designs, like Jimi’s Electric Linear Actuators and kits, can fit your current controls.

Conclusion & Next Steps

Servo cylinders are transforming poultry farming completely. They increase precision, conserve money, secure animal health and wellness, and let you do more with less. With Jimi as your trusted automation partner, you get professional advice, difficult products, and recurring support.

Your following step? Think about where servo automation can assist you expand. All set to take your ranch to the next level? Look into even more about Industrial Linear Actuators and allow’s start building your smarter, much better poultry home with each other.