Intro: The Demand for Accuracy in Modern Production

Imagine this: A high-tech vehicle rolls down the assembly line. Tiny bearings slip perfectly into engine blocks. Every part fits snug, right down to the micron. No leaks. No reworks. No wasted parts. That kind of perfection sounds futuristic but happens every day—thanks to servo cylinders.

Why do companies care so much about precision? The answer is simple. Product quality and reliability depend on it. In modern factories, near-perfect assembly isn’t a luxury; it’s a must. Even a hair’s width of error can send a whole batch of products back to square one. That’s why smart engineers now turn to servo cylinders for high-precision press-fitting tasks.

Understanding Servo Cylinders: The Foundation of Precision Assembly

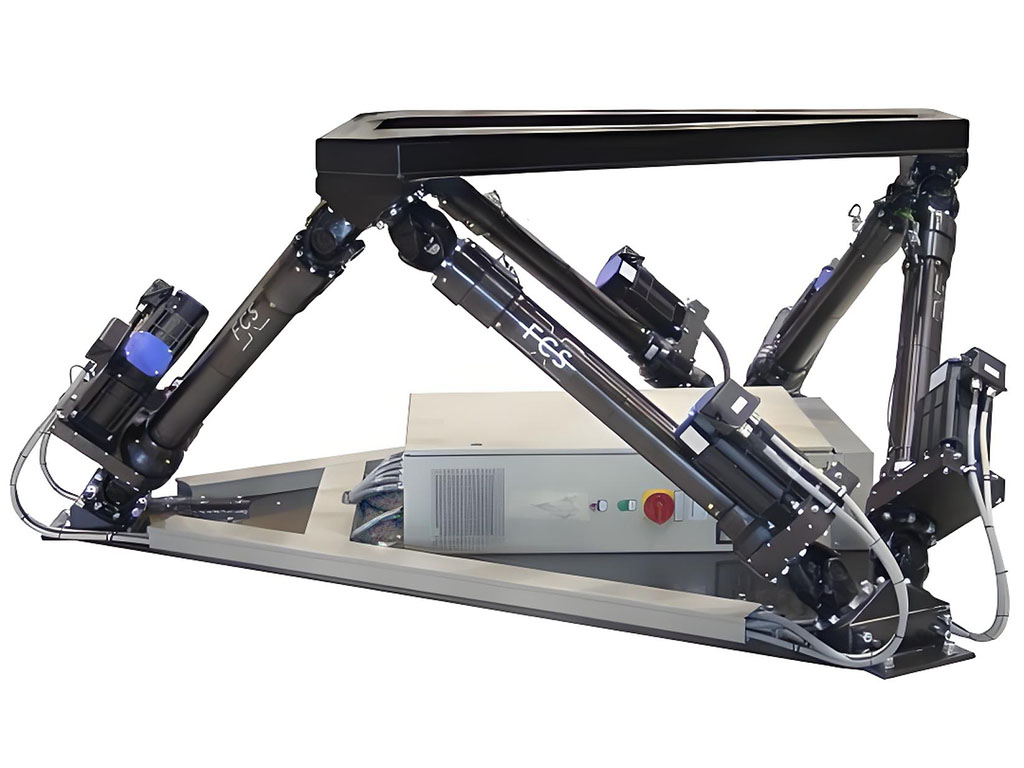

Servo cylinders aren’t magic, but they work like it. At their heart, you’ll find three key parts:

- A servo motor: This acts like a smart wrist, spinning with control and force.

- A ball screw: This simple screw turns the rotary motion of the motor into smooth, strong, straight pushing power.

- Sensors—load cells and encoders: These tiny watchers track both force and position with incredible detail.

With these parts, a servo cylinder pushes or pulls objects with exactness you can see. How does it differ from old air or hydraulic pistons? The answer is control. Where old cylinders move and hope to hit the right spot, servo cylinders know—thanks to real-time feedback.

Press-fitting needs this level of care. The procedure joins two parts by pressing them with each other, like fitting a peg right into an opening simply a little as well small. If you require things as well tough or too soft, you get cracks, loosened fits, or scrap. Servo cylinders fix this.

The Mechanics of High-Precision Control: Force, Position, and Profile

Servo cylinders shine through closed-loop control. This isn’t just fancy talk. Here’s how it works:

- Real-time sensors: Load cells check the force again and again. Encoders check position, tracking every step.

- Feedback: The servo motor listens to sensor signals and tweaks its moves instantly—think of it as checking its work as it goes.

- Programmable press profiles: Do you need a slow start and fast finish? Want to press a little, pause, then push again? Just tell the servo cylinder. It follows detailed press-fitting “recipes”.

- Micron-level accuracy and repeatability: After thousands of cycles, servo cylinders hit the same mark, every time.

The result? You get a process that moves at your pace, with your settings, and never misses a beat.

Unequaled Advantages: Why Servo Cylinders Outperform Traditional Presses

Superior Accuracy, Repeatability, and Quality Assurance

Servo cylinders leave hydraulic and pneumatic approaches in the dirt. No more leaks. No more oil mess. No more “good enough” fits. You get the same force and the same result, part after part.

For example, many manufacturers see scrap rates drop after switching to servo systems. One report showed that companies gained up to 25% better assembly accuracy compared to old methods (Precision Assembly Study).

Enhanced Flexibility, Programmability, and Rapid Changeovers

Need to change products on the fly? With servo cylinders, you just tap a screen. Update your press profile, and you’re ready for a new job. Quick transitions indicate less downtime and even more outcome, perfect for manufacturing facilities making many components.

Substantial Energy Efficiency and Cost Savings

Old hydraulic presses run pumps all day, burning electrical energy also when still. Servo cylinders only use power when they move. They’re kind on your power bill and the environment. Some shops report up to 70% energy savings (Energy Efficiency Institute). Fewer moving parts mean less fixing, less grease, and less hassle.

Comprehensive Process Monitoring, Data Acquisition, and Traceability

Ever wish your press could tell you when something’s off? With servo cylinders, that’s reality. Every press action gets logged. Want force-displacement curves in real time? No problem. Need to track which batch used which settings? Easy. This makes audits and quality checks simple. Predictive maintenance warns you before problems hit, saving money and headaches down the road.

Critical Applications of Servo Cylinders in High-Precision Press-Fitting

Automotive Industry Precision Assembly

Servo cylinders fit bearings, shafts, and bushings with power and care. One car maker cut its part rejection rate by 30% after making the switch (Automotive Manufacturer Case Study). Repeatability matters. You want each wheel, engine, or gearbox assembled to exact standards, and servo technology delivers.

Electronics and Micro-Assembly

Tiny parts like connectors or sensors need gentle, precise force. Servo cylinders press micro-components into circuit boards without bends, breaks, or misalignment. If you’re handling sensitive equipment, you’ll see instant benefits.

Medical Device Manufacturing

Sterile, safe, and reliable—all must-haves in this field. Servo cylinders assemble implants and sterile kits where perfection isn’t a request; it’s a requirement. Programmable control enables validation and compliance at every step.

Aerospace and General Industrial Applications

Aircraft parts, gear assemblies, and critical pins—these call for the best. The programmable force and traceable data help factories meet the tough standards set by aviation and space companies.

Selecting the Optimal Servo Cylinder for Your Application

Key Technical Specifications and Environmental Considerations

Not every servo cylinder suits every task, so focus on:

- Force and stroke: Pick a cylinder that matches your load and how far you need to push or pull.

- Speed and cycle time: Some jobs need speed, others need torque. Find the right blend.

- Environment: Is your factory a cleanroom? Does dust or vibration matter? Make sure your equipment can handle it.

For detailed specs, you can explore options such as the 250 Series Custom Electric Cylinder or 190 Series High Load Electric Cylinder at our China Electric Cylinder Factory.

Seamless Integration into Existing Automation Systems

Need your servo cylinder to “talk” with your factory controls? Most work with modern PLCs, HMIs, and industrial networks like EtherCAT and Profinet. Programming and setup are user-friendly, helping you combine old with new, fast.

Real-World Impact & Case Studies

Data from industry leaders shows big gains after moving to servo systems:

| Improvement | Typical Gain (%) | Reference |

|---|---|---|

| Accuracy | 15-25% | Assembly Study |

| Error Reduction | 30% | Automotive Case Study |

| Energy Savings | Up to 70% | Energy Institute |

FAQ

What is a servo cylinder and how does it work for press-fitting?

A servo cylinder uses a motor with feedback sensors to push or pull parts with precise force and distance. For press-fitting, it can join two pieces with just the right pressure, tracking every move to ensure a perfect fit.

How do servo cylinders achieve such high precision in assembly?

They use sensors that measure force and position in real time. The system changes just how difficult and how far it pushes at every instant, supplying micron-level accuracy every cycle.

What are the major advantages of using servo-electric presses over hydraulic or pneumatically-driven presses for press-fitting?

Servo presses are exact, trusted, energy-efficient, and easy to change. They cut waste, increase quality, and price less to run compared to older systems

What specific applications are best suited for servo press-fitting?

Servo systems shine in automotive fitting, electronics, medical devices, and anywhere you need accuracy and repeatability.

Can servo cylinders provide real-time process monitoring and data feedback?

Yes! They track force, placement, rate, and extra– and can log or display this data for quality assurance and predictive maintenance.

Conclusion & Next Steps

Today’s factories run on accuracy and control. Servo cylinders for high-precision press-fitting bring just that—less waste, lower costs, and products you can trust.

We at Jimi Technology know this industry inside and out. With our years of hands-on experience and a full line of servo cylinders, electric linear actuators, and automation controls, we help you solve even the toughest assembly problems. Our equipment meets the tightest specs, so you get top results with every press.

Ready to boost your production? Explore our Electric Cylinders or talk to our team of experts today. Bring Jimi’s expertise to your line—and join the future of precision manufacturing.