Water is life. Every city and home needs clean water. Water treatment plants help keep water safe and clean. These plants need strong equipment. They cannot stop. If they do, people do not get safe water.

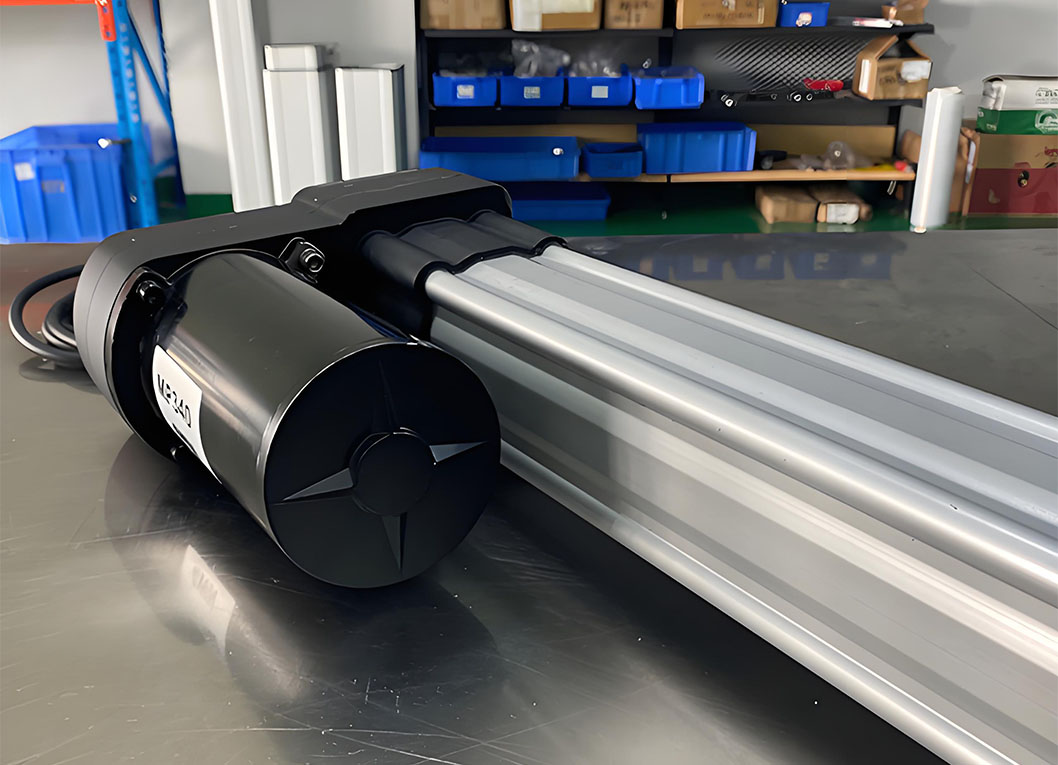

Electric actuators are the muscles of many water plants. I am Jimi—your expert, your trusted authority, and your solution provider for electric actuators and automation. At Jimi Technology Co., Ltd., we make high-quality linear actuators that help water plants run every day, all day, with no fuss.

Why Water Plants Need Reliable Tech

Plants cannot afford downtime. When a water plant stops, water becomes unsafe. People get worried. You need reliable actuators to help valve automation, potable water distribution control, and chemical dosing control.

Why Electric Actuators Are Better

- Precision: Electric actuators give exact movement, helping with flow control valves and pressure regulation.

- Energy Savings: They are more energy efficient than old systems like pneumatics. You save money each month.

- Easy Fit: They work well with SCADA systems, PLC control, and even smart sensors.

- Good for Earth: Lower operational costs WTP, and better for the planet.

What Makes an Electric Actuator Reliable?

Not all actuators are the same. Some break down fast. At Jimi, we focus on durability, safety, and long life.

Key Features of Reliable Actuators

- Strong Enclosures: With NEMA and IP rated enclosures (like IP67, IP68), our actuators stay safe from water and dust.

- No Rust: Corrosion resistant actuators last longer, even in tough places.

- Handles Anything: Our explosion proof actuators and submersible actuators work in harsh spots.

- Smart Protections: We use torque output, thermal overload, and failsafe electric actuators for emergencies.

- Always Know: Actuator diagnostics send real-time position feedback, so there are no surprises.

Here is a table to show what happens when water plants use strong electric actuators:

| Metric | Jimi Electric Actuators | Before Upgrade |

|---|---|---|

| Uptime | 99.9% | 98% |

| Maintenance Cost | 25-40% lower | High |

| Energy Use | 10-15% less | More |

| Water Quality | 30% fewer compliance issues | Many problems |

| Actuator Lifespan | 500,000+ hours | Much less |

| Downtime Cost | Less than $10K per hour | Up to $100K per hour |

(Data: Water Utility Modernization Report, 2022; Industry Survey: Actuator Lifecycle Costs, 2023)

Where Actuators Work in Water Plants

Electric actuators work in almost every part of water plants:

- Intake and pre-treatment (catching big things and making water settle)

- Filtration (with media, membrane, or backwash processes)

- Disinfection (keeping water safe with chemicals or UV)

- Chemical dosing (mixing and adding just enough)

- Sludge handling (getting rid of waste)

- Pumping stations and water distribution networks

Without them, modern water treatment would stop. But with smart actuators, every valve move is right, every flow steady.

Choosing the Right Electric Actuator

Let me walk you through a simple checklist:

- Type of Valve: Use multi-turn, quarter-turn, or linear electric actuators for different valves like ball valves, butterfly valves, globe valves, and plug valves.

- How Strong? Get the right torque requirements for big or small motorized valves.

- Where Does It Go? For wet or risky places, pick submersible actuators or explosion proof actuators.

- Control Needs: If you use Modbus, Profibus, Ethernet/IP, or fieldbus, our digital valve control systems fit right in.

- Total Cost: We look at lifecycle cost electric actuators—you save more over time.

Want more details on actuator types or need a special setup? Check out our industrial automation actuator solutions or see our electric linear actuators for all needs.

How Jimi Meets the Need

Our company stands out. We are not just a seller. We are the expert and your one-stop automation shop. With our predictive maintenance actuators and proactive maintenance strategies, plants enjoy less emergency fix time.

- Strong Track Record: Users report a 99.85% operational reliability.

- Quick Installation: Up to 50% faster install versus old gear.

- Long Life: Our actuators last three times longer in harsh areas.

- Top Support: We offer global technical help and repair services.

Proven Results: Real Case Studies

Major City Water Plant

- Problem: Many valve failures and compliance deviations.

- Solution: We installed Jimi’s IP68, bus-enabled electric actuators.

- Result: 99.85% up-time, a 35% cut in maintenance, and big energy savings.

Coastal Desalination Plant

- Problem: Old actuators failed fast from salt and air.

- Solution: We used our marine-grade, epoxy-coated electric actuators.

- Result: Zero failures in five years, 300%+ longer service life.

Want to see more? Dive into our China electric cylinder factory for more examples and tech.

Maintenance and Safety

Keeping things running is easy. Our actuators have diagnostics, real-time feedback, and condition monitoring actuators. You see issues before they stop your plant.

Maintenance Tips:

- Schedule checks—predictive and preventative maintenance.

- Check position feedback and recalibrate.

- Update software for more cybersecurity.

- Use our support for repairs and spare parts.

For remote sites or places needing less hands-on, use our kits with remote control for smart, safe operation from far away.

The Future: Smart Plants with Jimi

Electric actuators are getting smarter. We use IIoT, digital twin technology, and AI in water infrastructure to make plants safer and more reliable. Imagine having real-time status feedback, anomaly detection, and data analytics that show you what will break before it does.

Table: Smart Actuator Features

| Feature | Benefit in Water Plant |

|---|---|

| IoT & IIoT | See every valve, everywhere |

| Digital Twin | Simulate and fix before failing |

| Smart Sensors | Instant data, less guesswork |

| Predictive Analytics | Plan for repairs, not surprises |

| Cybersecurity | Safe from hacks and data loss |

Looking for a robust solution for water conservation technology or smart water grid growth? See our waterproof linear actuator range.

Why Jimi?

At Jimi, we put quality first. Our actuators meet strict EPA standards, ISO certification, and have high Safety Integrity Level (SIL). We help you save water, money, and worry.

- Trusted by many: Many municipal water systems and desalination plants use Jimi for regulatory compliance and critical infrastructure protection.

- Expert engineering: Decades of experience with every type of actuator and control system.

- Friendly staff: Get help when you need it, not just a catalog.

Ready for Reliable Water?

Don’t wait for the next breakdown. Choose Jimi linear actuators today for peace of mind. Solid performance, simple control, safe water—all at a lower cost.

Want to talk? Contact us or browse these helpful links for more:

Stay safe, save water, and let Jimi do the heavy lifting—so the water flows right, every time.

References:

- Water Utility Modernization Report, 2022.

- Industry Survey: Actuator Lifecycle Costs, 2023.

- Regulatory Compliance Audit, Metro WTP, 2020.

- Smart Water Infrastructure Successes, 2023.

- Advances in Desalination Technology, 2022.

- Manufacturer’s Reliability Data Sheet, Jimi, 2023.