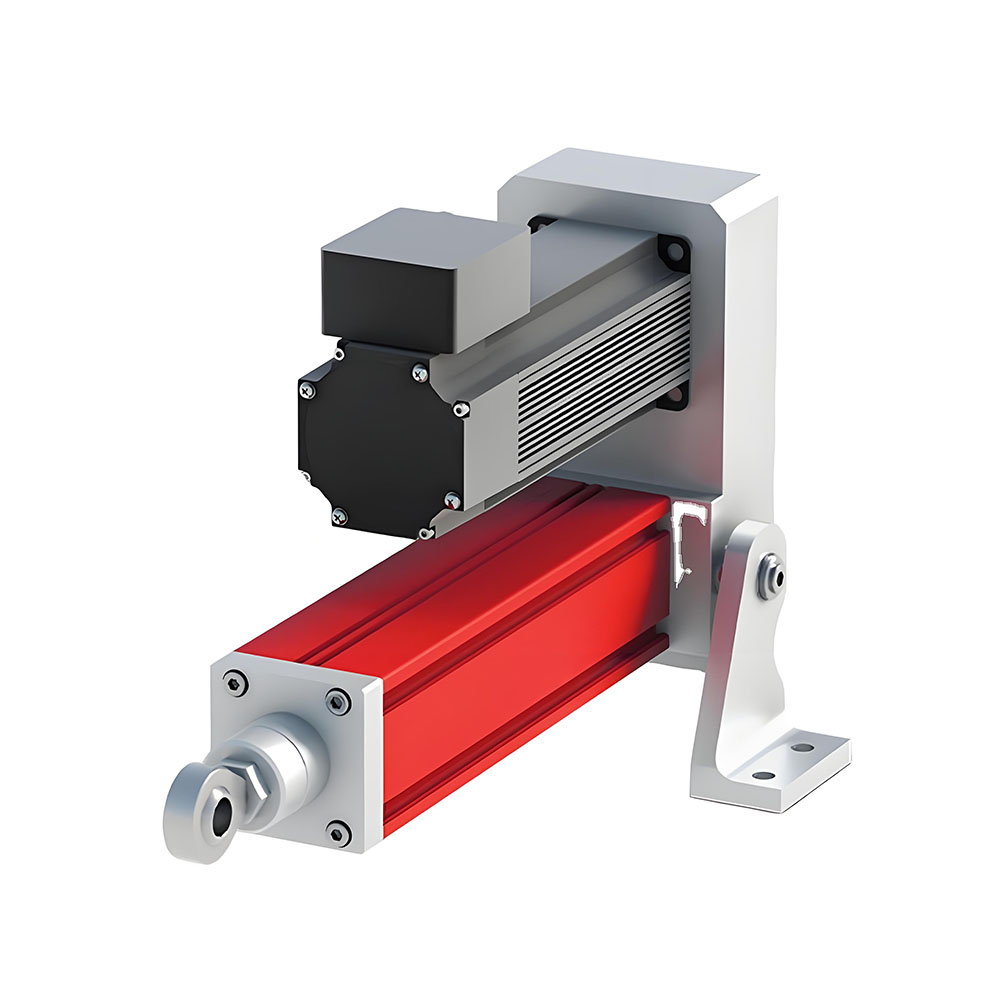

250 Series 30T Servo Linear Actuator | Heavy Duty Cylinder

The 250 Series 30T Servo Linear Actuator delivers 30 tons of force for demanding industrial motion, offering precision, reliability, and efficiency.

Description

Meet the 250 Series 30T Servo Linear Actuator—a powerhouse built to conquer the most demanding industrial motion challenges. With 30 tons of relentless force at your command, this heavy-duty electric cylinder doesn’t just push boundaries; it sets new ones for precision, reliability, and efficiency in automation.

Features and Benefits

-

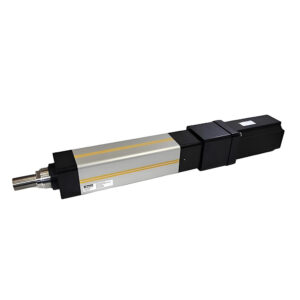

Rugged Construction with High-Grade Materials: Crafted for extreme duty, the 250 Series 30T combines robust housings—often high-grade aluminum or stainless steel—to thrive in industrial environments where ordinary equipment fails. You can rely on consistent performance, cycle after cycle.

-

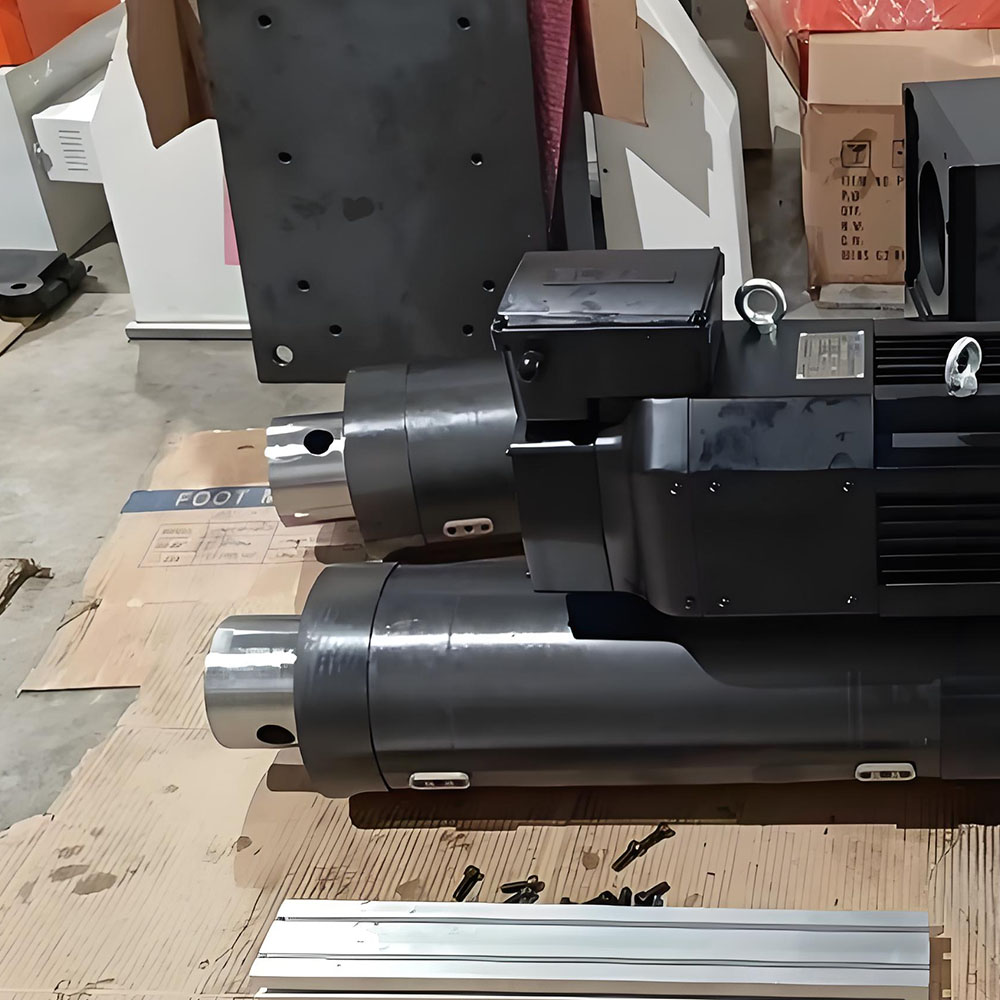

Extreme Force Output: Delivering up to 30 tons (60,000 lbs, ~270 kN), this actuator provides the muscle for heavy lifting, metal forming, and large valve actuation, replacing the mess and maintenance of hydraulics with the finesse only electromotion offers.

-

Precision Programmable Motion: This servo motor linear actuator transforms the tiniest command into smooth, repeatable, and programmable linear movement. Expect ±0.01 mm repeatability for each stroke—vital for high-precision tasks in material testing, automated assembly, and simulation.

-

Energy Efficiency Designed In: Swap out inefficient hydraulics for dramatic energy savings—up to 80% in intermittent duty cycles. Cut costs, quiet your workspace, and slash your environmental footprint.

-

IP-Rated Protection: With models typically sealed to IP65 or better, dust and water don’t stand a chance. Install with confidence in steel mills, foundries, or even outdoors—perfect for harsh environments and continuous-duty industrial applications.

-

Low Noise & Maintenance-Free: No more roaring pumps or oil leaks. This electric press actuator runs quietly and offers maintenance-free operation for years, making it as easy on your crew as it is on your OPEX.

Wide Applications

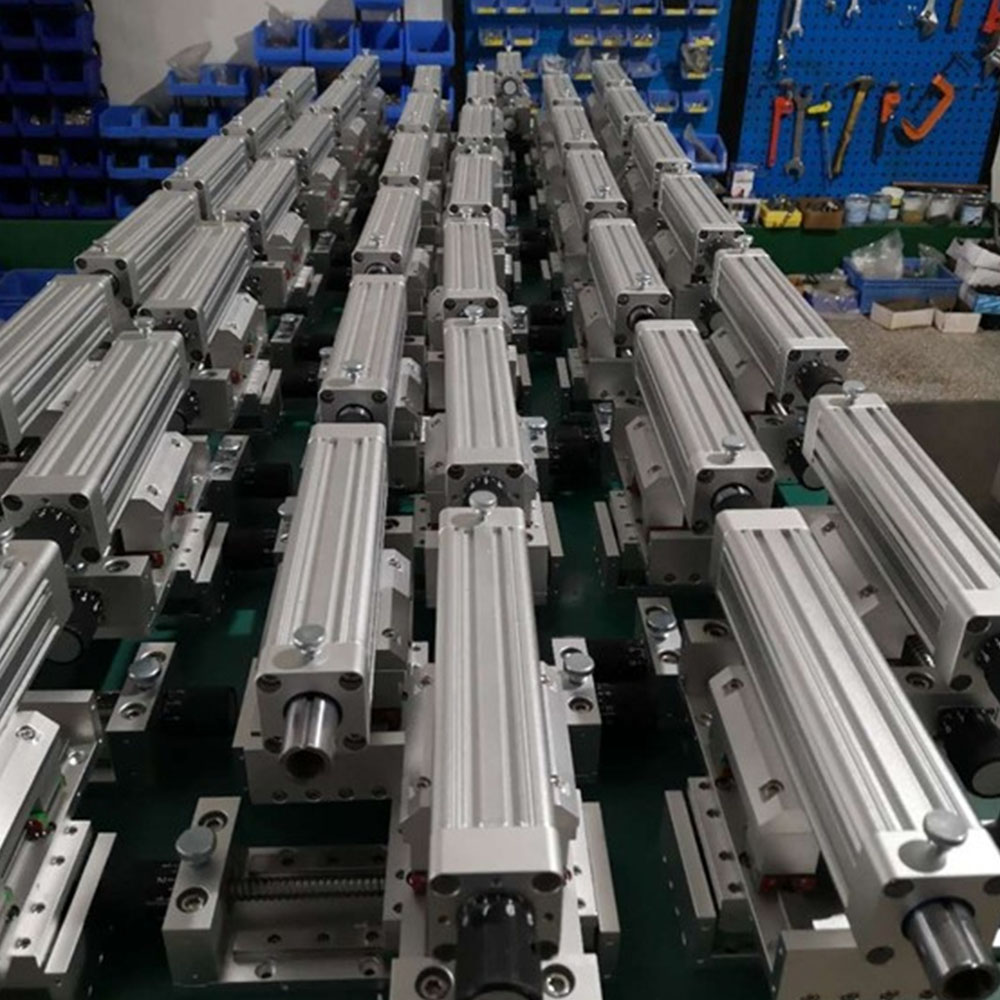

Whether you’re modernizing press lines, automating heavy material handling, or pushing the envelope in testing labs, the 250 Series 30T delivers. It’s tailored for advanced manufacturing, steel and foundry applications, fatigue testing systems, structural simulation, automotive assembly, and any place where heavy-duty precision matters most.

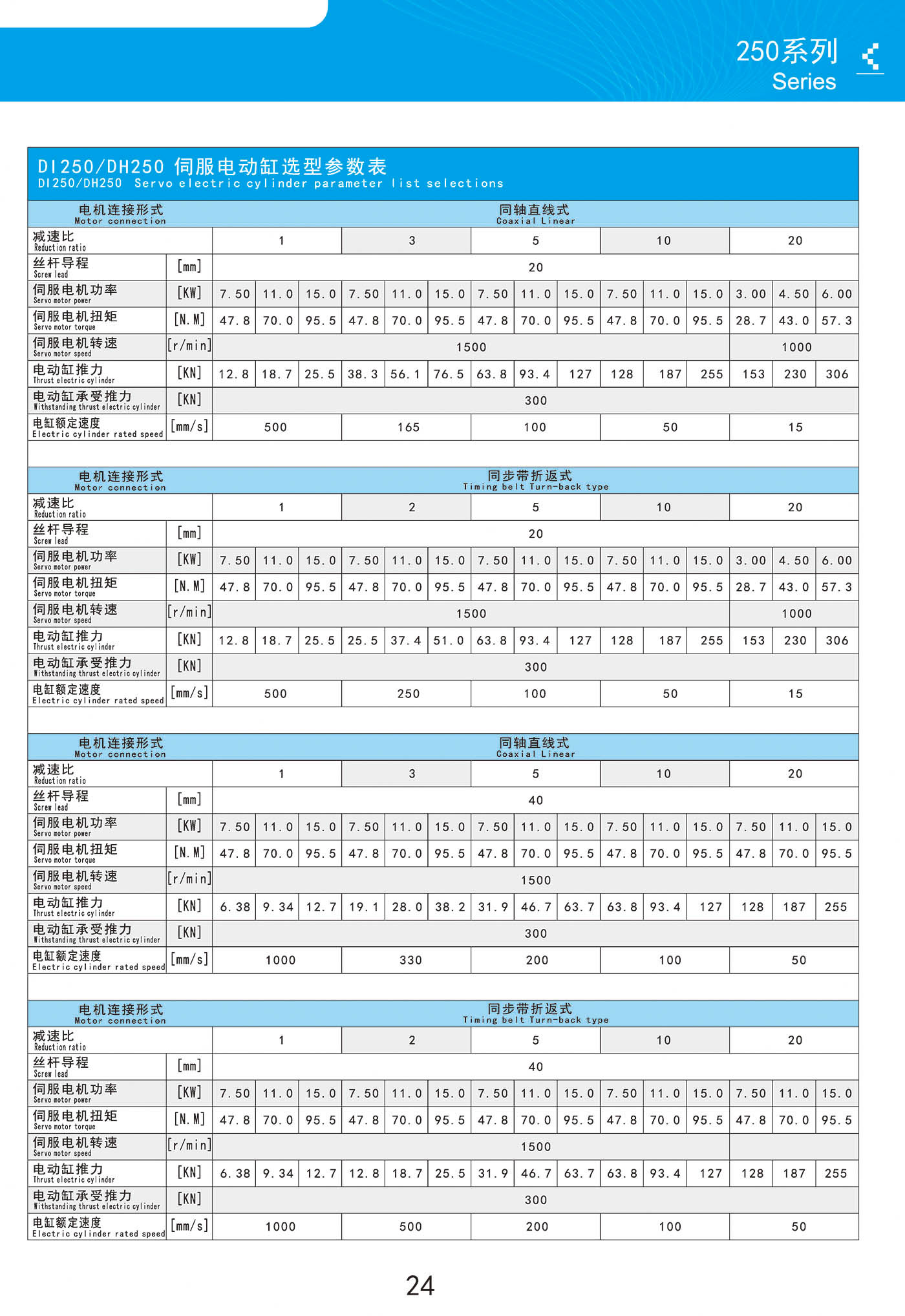

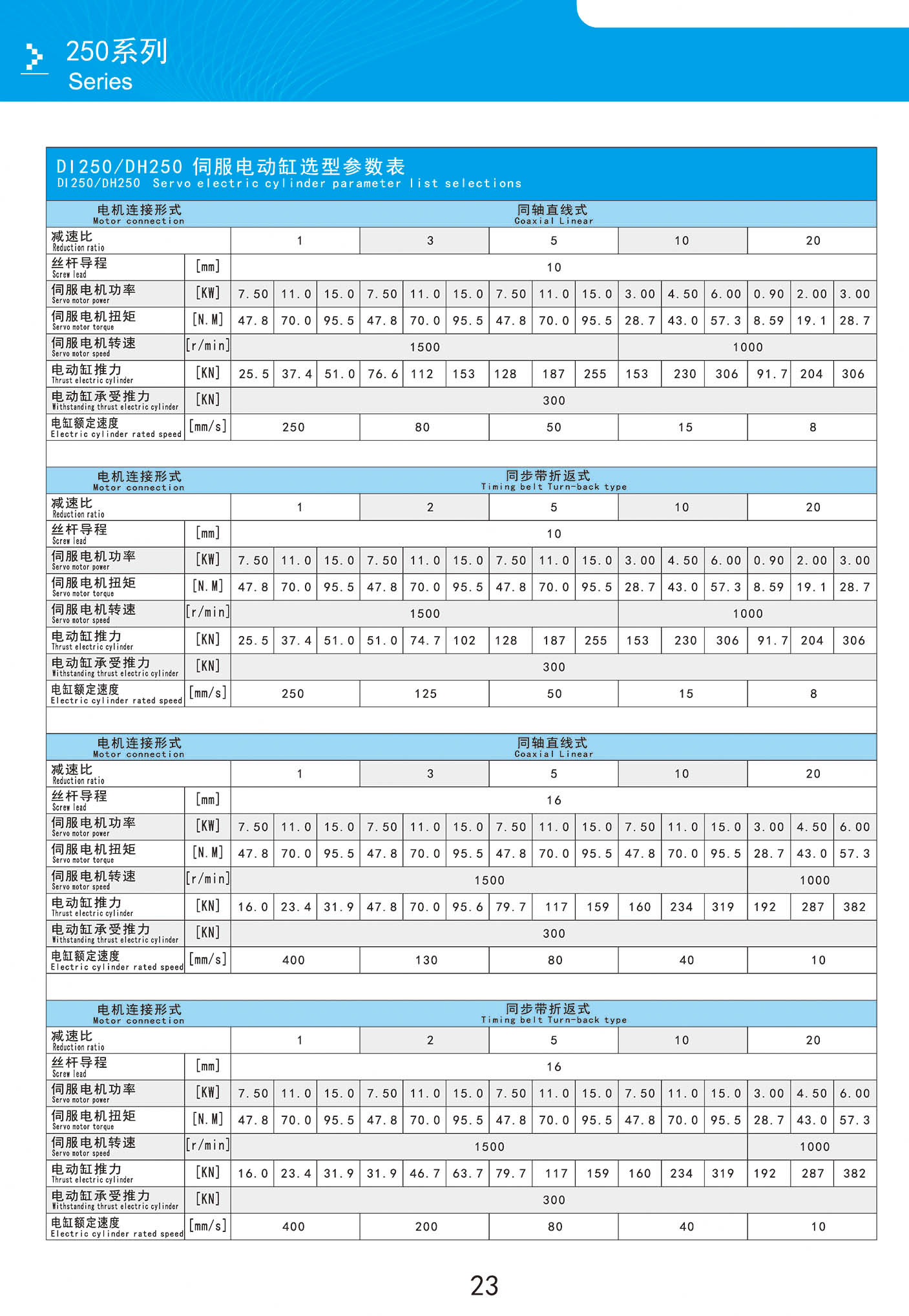

Specifications

- Force: 30 Tons (60,000 lbs / ~270 kN) continuous thrust

- Speed: Typical range 50-500 mm/s (up to 1000 mm/s for custom configurations)

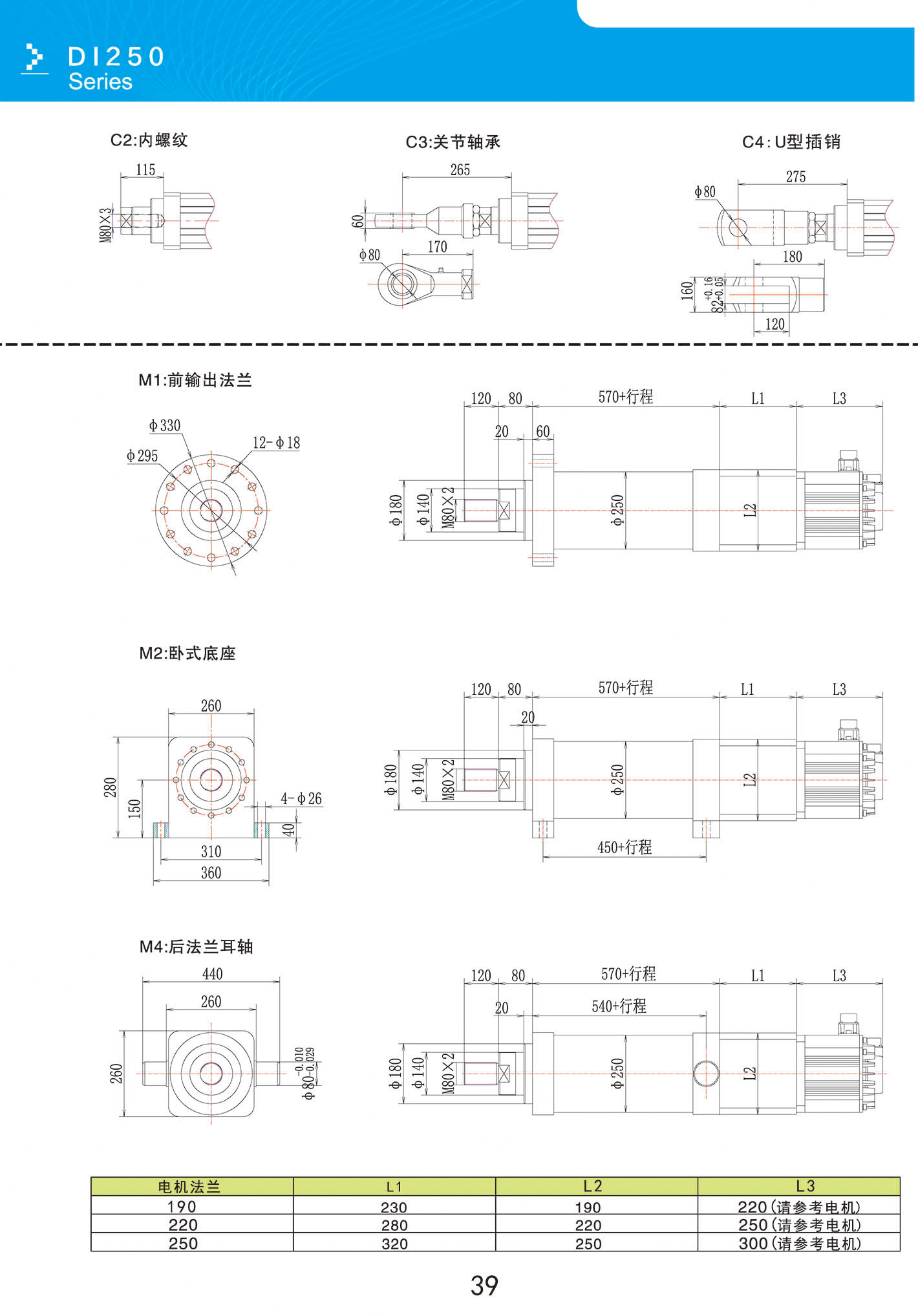

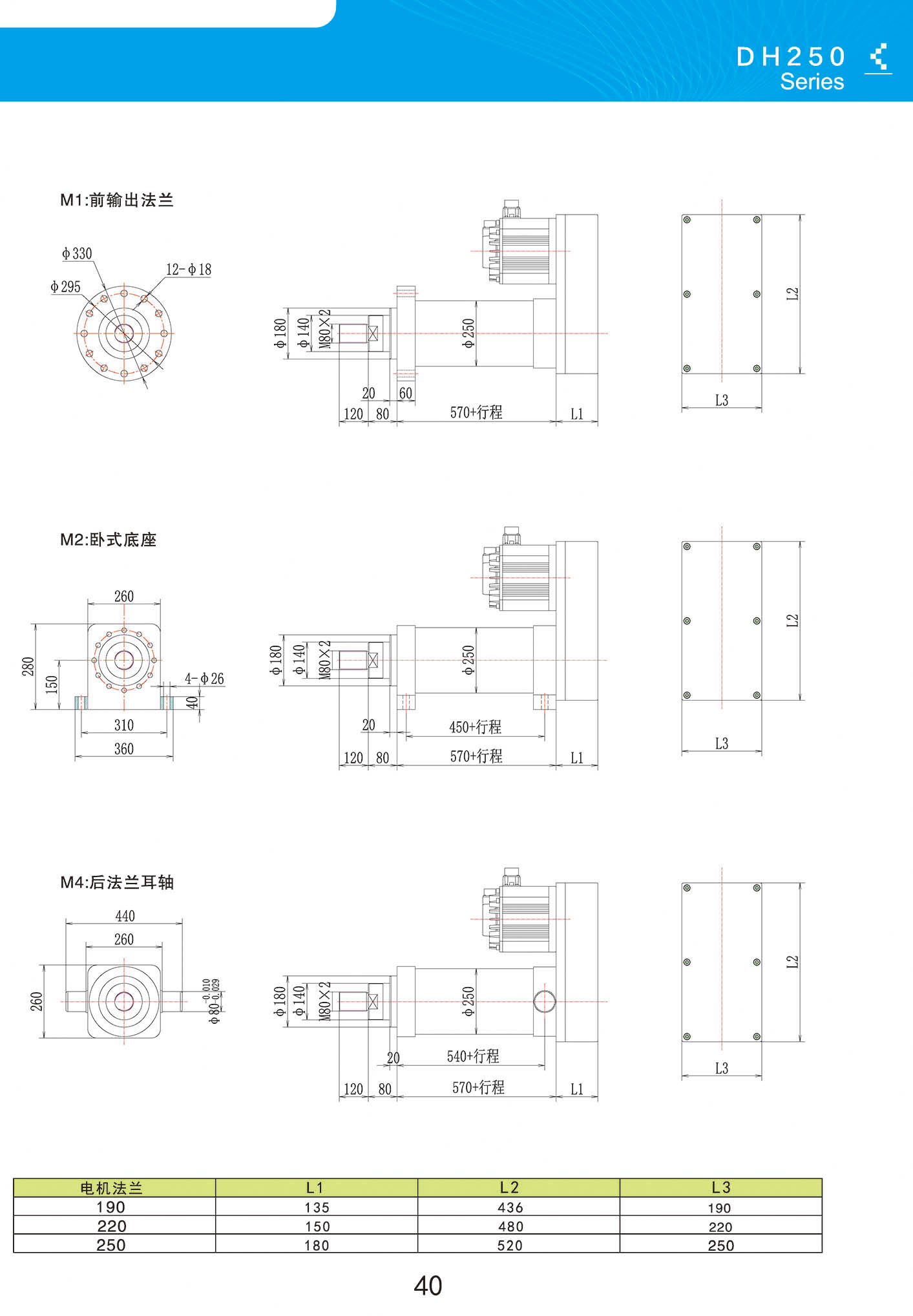

- Stroke Length: Customizable, typically up to 1500 mm or more

- Input Voltage: Mainstream industrial (such as 230V, 400V, or per application, supporting global standards)

- Protection Rating: IP65 or greater (water/dust-tight for industrial/aggressive environments)

Technical Support

Jimmy Technology equips you with more than hardware. Get detailed CAD models, comprehensive datasheets, and precise wiring diagrams. Our team of engineers ensures your installation, troubleshooting, and integration with platforms like Siemens, Rockwell, or Mitsubishi PLCs is as seamless as possible.

Conclusion

Choosing Jimmy Technology means you demand—and receive—the industry’s benchmark for innovation, quality, and heavy-duty actuator reliability.