Is Your Machine Always Breaking Down?

Let’s talk. If your factory, robot, lift, or line keeps stopping, it is not fun. Your boss gets upset. You feel stress. Work stops. Money is lost.

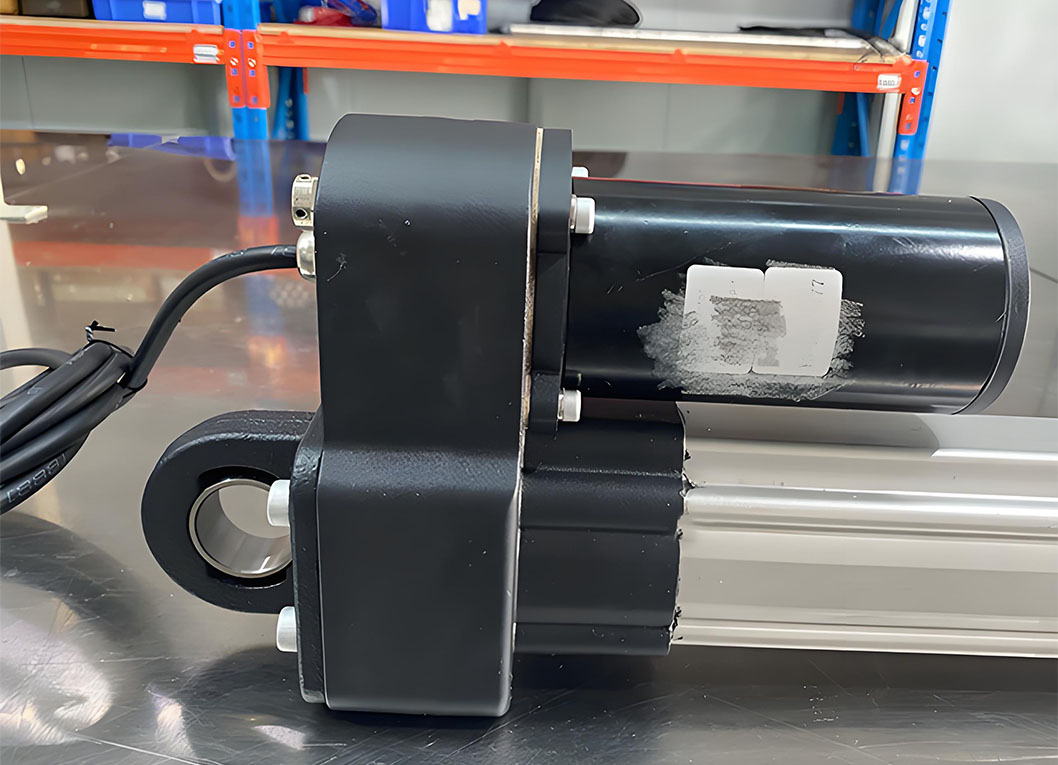

What makes your line stop? Often, it’s a linear actuator failure. These smart parts help things move in or out, up or down, round or straight. When they’re broken, nothing works.

But don’t worry. With predictive maintenance, you can say goodbye to surprise breakdowns and hello to easy work days.

What Is A Linear Actuator? Why Is Downtime Bad?

A linear actuator is a tool that changes electric power to a strong, straight push or pull. Think of a TV lift that goes up and down. Or a robot arm reaching out. Maybe your desk goes up and down. That is a linear actuator, using linear motion.

But what happens when it fails? The whole line stops. You could lose lots of money quick. Sometimes, repairs cost more than the actuator itself. No one wants that.

You Need Predictive Maintenance

Let’s look at what predictive maintenance gives you:

- Less Down Time. When you see problems early, you fix them quick.

- Save Money. Fix small problems before they turn big. No more big break bills.

- Better Planning. When you know what’s wrong, you fix it on your time—not in a crisis.

- Longer Life. Your actuator lasts longer when you take care of it early.

- More Safety. No more surprise accidents from failed parts.

- Smart Choices. You get data to plan your work and even your spending.

When you switch from reactive ("oh no, it broke!") or preventive ("maybe fix it every month, just in case?") to predictive ("here comes trouble–let’s stop it early!"), you win.

What Can Go Wrong with Linear Actuators?

Many things, big and small:

- Bumpy Bearings. Bearings get worn or dirty.

- Motor Troubles. The motor may get too hot, use too much energy, or wear down.

- Not Enough Oil. Lubrication gets old or runs out.

- Dust, Wet, or Too Hot/Cold. Harsh places break actuators fast.

- Wrong Signals. Sensors and encoders can fail, sending the actuator to the wrong spot.

If you watch for these problems, you can stop them before they break your line.

How Does Predictive Maintenance Work for Linear Actuators?

Let’s break it down:

- Actuator Health Monitoring: Use Smart Sensors

- Vibration Checks: Sensors listen for odd shakes in motors or screws.

- Temperature Reads: Sensors spot parts that run too hot.

- Current Draw Checks: Finds if a motor uses odd amounts of electricity.

- Acoustic Listening: Sensors pick up weird noises from cracking or worn-out parts.

- Position and Force Sensors: Tell if something is going too far or using too much force.

- Lubrication Tests: Watch for dirty oil or low lubricant.

- Smart Data Gathering

Data goes from machines to systems like IIoT (Industrial Internet of Things) using wireless sensors and edge computers. No wires needed! Data goes to the cloud. It’s always up to date.

- Powerful Analysis

This is where the magic happens:

- AI (artificial intelligence) and machine learning find odd patterns in the data.

- Anomaly Detection tells you if anything is not normal.

- Predictive Analytics shows you when—exactly—things may go bad.

- CMMS Integration: Your work order arrives before disaster strikes.

- Easy to Use

Dashboards and alerts make the data simple. You get a message on your phone or computer to check or fix something.

Step-by-Step: Predictive Maintenance for Your Actuators

Want to start? Here’s how:

- Assess. See which actuators matter most.

- Choose Sensors. Pick the right ones for your motors, screws, and environment.

- Set Up Data Tools. Use software and storage for your data, like a CMMS.

- Collect and Learn. Gather the first set of data to see what "good" looks like.

- Train the System. Teach your AI to spot danger.

- Test. Try on one line or actuator.

- Train the Team. Show everyone how to use the tools.

- Always Improve. Review, adjust, repeat!

Real Results: Predictive Maintenance Works

See what happens when you use these smart tools:

| Benefit | Result | Reference/Example |

|---|---|---|

| Downtime Reduction | Up to 75% less unplanned downtime | PwC Industry 4.0 survey; CNC plant avoided 200 hours lost |

| Lower Costs | 25-30% cut in costs | Deloitte Intelligent Assets |

| Longer Actuator Life | 20-40% more years | Field experience, linear actuators |

| Higher ROI | 10X or more (even up to 400%) | McKinsey Industry 4.0 Report |

| More Output | 5-10% faster production | OEE improvement data |

| More Safety | 20-40% fewer incidents | Real-world safety tracking |

| Less Storage Needed | 20-50% fewer spare parts bought | "Just-in-time" supply |

| Fewer Failures | Up to 70% fewer surprise failures | Plant maintenance logs |

Cases

CNC Machine:

With vibration and temperature checks, a shop caught 3 bad bearings early. Saved 200 hours of downtime. Saved $150,000.

Packaging Line:

Sensors found friction in a push unit. Fixed it before it jammed. Saved a whole day—$50,000 saved.

To see products for special uses, check out Industrial Automation Actuators or our Servo Linear Actuator Factory.

You can find more about Electric Linear Actuators or see top Ball Screw Actuators.

Challenges to Watch Out For

- Upfront investment in sensors and software.

- Need for good, clean data.

- Connecting old machines (PLC, SCADA) to new systems.

- Training workers on new tech.

- Cyber security: Keep your data safe.

The Future Is Bright (and Smart)

What is next? Imagine:

- Digital Twins: Virtual models of your actuator for perfect testing.

- Self-healing Machines: Fix themselves before you even know there’s a problem.

- Sharper AI: Even better predictions, less human work.

Why Choose Jimi (Jimi Technology Co., Ltd.)?

You want a partner, not just a supplier. Jimi means expertise. Our linear actuators, TV lifts, and automation systems lead the field.

Why do engineers, plant managers, and innovators trust us?

We offer:

- Cutting-edge products: China Linear Actuator Manufacturer for quality, reliability, long life.

- Strong support: We are not just about sales. Our pros help from planning to setup to service.

- Smart solutions: Full product lines, from Ball Screw Actuators for CNC to Electric Linear Actuators for automation.

- Custom help: Unique needs get unique answers from our engineers.

When you need long-lasting, smart, and efficient actuators, trust Jimi. We know predictive maintenance, linear actuator diagnostics, and automation inside and out.

Ready To End Surprises? Let’s Move Forward

Don’t let downtime, high costs, and stress run your day.

Use predictive maintenance. Make your linear actuators work smarter, not harder.

Let Jimi be your guide. Check more at China Linear Actuator Manufacturer.

References

- PwC, Global Industry 4.0 Survey (2018)

- Deloitte, The Rise of Intelligent Assets (2017)

- McKinsey, Industry 4.0 Report (2016)

Try, learn, and see the difference. That’s the Jimi promise. Bold motion, zero surprises, more smiles.