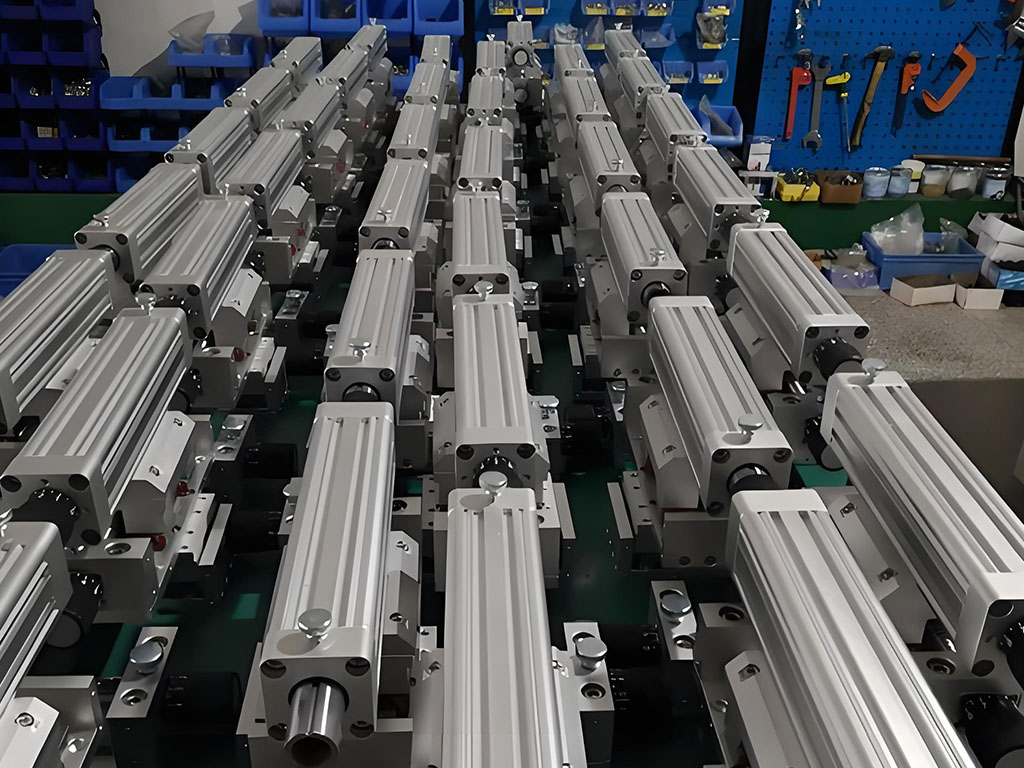

Photo this: a manufacturing facility packed with little circuits, every 2nd matters and each part sits in just the right spot. That’s what makes 3C electronic devices– computers, interactions, and consumer gizmos– so challenging. The secret heroes behind the scenes? Micro electric cylinders. These small marvels drive the best factories in China and worldwide. In just a moment, you’ll see how this basic tool makes all the distinction.

Unboxing the Technology: What Are Micro Electric Cylinders?

Micro electric cylinders are small machines that turn electric power into straight-line pushes or pulls. Think of them as robot muscles. They use a little motor (like a servo or stepper motor) with a twisty screw inside. This setup moves a rod in and out, right where you want it.

Here’s what’s inside:

- Motor: Makes things move.

- Screw/Nut: Turns spinning power into straight movement.

- Rod or Slider: Pushes and pulls.

- Encoder: Keeps track of where things are.

- Controller: Tells it when and how fast to move.

Unlike old-school air cylinders or hydraulic pistons, micro electric cylinders don’t need loud air tanks or messy oil. Plug them in, set a command, and you’re rolling. There’s no lost power, and every little thing occurs easily. That’s why an increasing number of suppliers are changing to electric, specifically where area is tight.

Did you know? The global industrial linear actuators market is set to reach $5.7 billion by 2028, with huge growth in electronics (Markets and Markets).

Why 3C Electronics Demands Micro Electric Cylinders: Addressing Industry Challenges

Walk into a 3C electronics plant. You’ll see rows of parts tinier than your fingernail: chips, resistors, buttons, glass screens. Each must fit together just right, fast, and without dust or damage.

What problems pop up?

- Precision: Moves must be accurate to less than the width of a hair (that’s about 10 micrometers or less).

- Speed: Finished devices roll off the line in seconds.

- Cleanliness: Even a speck of oil or dust could ruin a whole batch of phones.

- Volume: Tons of parts, over and over, day and night.

- Changeovers: Devices change fast. This week, it’s a smartwatch. Next week, VR headsets.

Pneumatic systems waste lots of air and can leak, leading to costly mistakes. Hydraulics need careful handling because spills mean shutdowns. Micro electric cylinders cut out all those troubles. They’re clean, quiet, and don’t waste energy when not moving.

Precision in Motion: Key Applications of Micro Electric Cylinders in 3C

Automated Pick-and-Place Operations for Delicate Components

Every tiny chip, LED, or button in your favorite gadget lands exactly where it should, thanks to these compact heroes. Micro electric cylinders handle components gently, moving at the perfect speed and pressure. In surface-mount technology (SMT), they pick up minuscule parts and set them on circuit boards without snapping or bumping them.

- Less breakage.

- More products made every hour.

- Every piece always fits just right.

High-Accuracy Assembly of Electronic Devices

Think about snapping a camera onto a phone or pressing a screen into place. The whole process needs just the right touch—not too hard, not too soft. Micro cylinders handle those tricky steps. They press, insert, and fasten with perfect control, leaving no room for error.

- Fewer duds reach your customers.

- Smoother lines, fewer delays.

Precision Testing, Inspection, and Dispensing Tasks

Tests sometimes mean pushing a button, other times gently inserting a connector. Need to place a dab of glue right at the edge of a circuit? Here too, micro electric cylinders shine. They work with sensors and cameras to run quality checks and spot problems, catching issues early. You get a smoother process and better products.

- No more glue messes or bad connections.

- Each unit passes with flying colors.

The Undeniable Advantages: Why 3C Manufacturers Choose Electric

Unmatched Precision and Repeatability

Micro cylinders nail every position—sometimes even better than a single micron. Over millions of moves, they stay true. No jerkiness, no drifting. Pneumatic setups can falter as air pressure changes, but electric stays steady.

- Get positions right, every time.

- No more complaints about misaligned parts.

Enhanced Speed, Control, and Programmability

Set your cylinder to move fast, slow, or just right. Need to speed up the line? Adjust on the fly. These cylinders plug into big control systems (like PLCs or robot brains), so you can run wild motion sequences with ease.

- Change product lines without retooling.

- Quick cycle times mean more units per day.

Energy Efficiency and Environmental Benefits

Old air systems gulp power. Electric cylinders sip it. Power only flows when the cylinder moves, unlike air systems that keep chugging even at rest. That saves money with every shift.

- Up to 80% less energy use (see this source).

- No air or oil leaks—good for cleanrooms (even ISO Class 1–5 certified).

Lower Total Cost of Ownership (TCO)

After setup, maintenance is low. No seals to swap, no compressors to fix. Plus, these units last longer. What you spend upfront, you save in repairs and power bills later.

- Tiny downtime.

- Big savings long-term.

Navigating Challenges and Technical Considerations for Implementation

You’ll want the right fit for your factory. Think:

- How much force do you need?

- How fast should it move?

- How long do the parts travel?

Also, check your conditions. Is it hot, humid, or full of static? Choose the right servo linear actuator or stepper motor actuator for your setup. These solutions slot into robots or vision systems easily, but your team may need to adjust programming or learn new tricks.

Jimi’s experts help you plan and select the best model for your unique needs—we walk you through the specs, controls, and setup.

The Future of 3C Automation: Micro Electric Cylinders at the Forefront

3C factories race ahead. Smart sensors and Industry 4.0 features (think the internet for machines) let you spot hiccups before they grow. Imagine a line where every motion is tracked, logged, and made better over time. Micro electric cylinders fit here perfectly.

As devices keep shrinking, so do the cylinders. Power grows. Setup gets easier. All this means less waste and more green manufacturing.

“The convergence of IoT, AI, and advanced linear motion control is paving the way for truly adaptive and efficient 3C manufacturing lines, where micro electric cylinders are a core enabler.” (Read more)

Frequently Asked Questions

What is a micro electric cylinder and how does it work?

It’s a small device that uses electricity to push or pull in a straight line—like a muscle for machines. A motor spins a screw, moving a rod with high accuracy.

Why are electric cylinders preferred over pneumatic for 3C electronics?

They’re cleaner, quieter, more accurate, need less upkeep, and waste much less energy.

What specific applications do micro electric cylinders have in smartphone assembly?

They pick and place fragile bits, assemble screens, press connectors, and run tests—mostly everything that needs precision.

How do micro electric cylinders improve precision in electronics manufacturing?

They nail positions better than 10 microns, repeat perfectly, and avoid the faults and drift common in air-powered cylinders.

Are micro electric cylinders cost-effective in the long run for high-volume production?

Yes. While the starting price is sometimes higher, you save heaps on energy, repairs, and slowdowns, so the total cost is much lower.

Can electric cylinders operate in cleanroom environments required by electronics?

Absolutely. They’re oil-free, resist dust, and many models earn ISO cleanroom ratings.

Why Jimi is Your Trusted Partner in Motion

We at Jimi Technology know the ins and outs of 3C electronics. For years, we’ve built micro electric cylinders that factories rely on, making big gains in both speed and quality. Our lineup includes servo motor actuators, light-duty miniature actuators, and the most advanced ball screw actuators you’ll find.

- Trusted by top manufacturers.

- Easy integration with robotics and vision systems.

- Quality tested to meet the highest standards.

Explore more about our Electric Linear Actuators, Servo Motor Actuators, and Actuators with Position Feedback to see which solution is right for your needs.

Ready to see precision and speed in action? Contact Jimi Technology today for a demo, or check our China Electric Cylinder Factory page to start building your ideal automation line. Upgrade now—and unlock a smoother, greener, and smarter future in electronics assembly.