Envision it. You walk into a hospital space. The nurse presses a switch, and the bed moves up or down in silence. The client’s back lifts smoothly, no jerking– no initiative. In that simple movement, you see comfort, safety, and cutting-edge care.

What Are Medical-Grade Electric Cylinders and Why Are They Crucial?

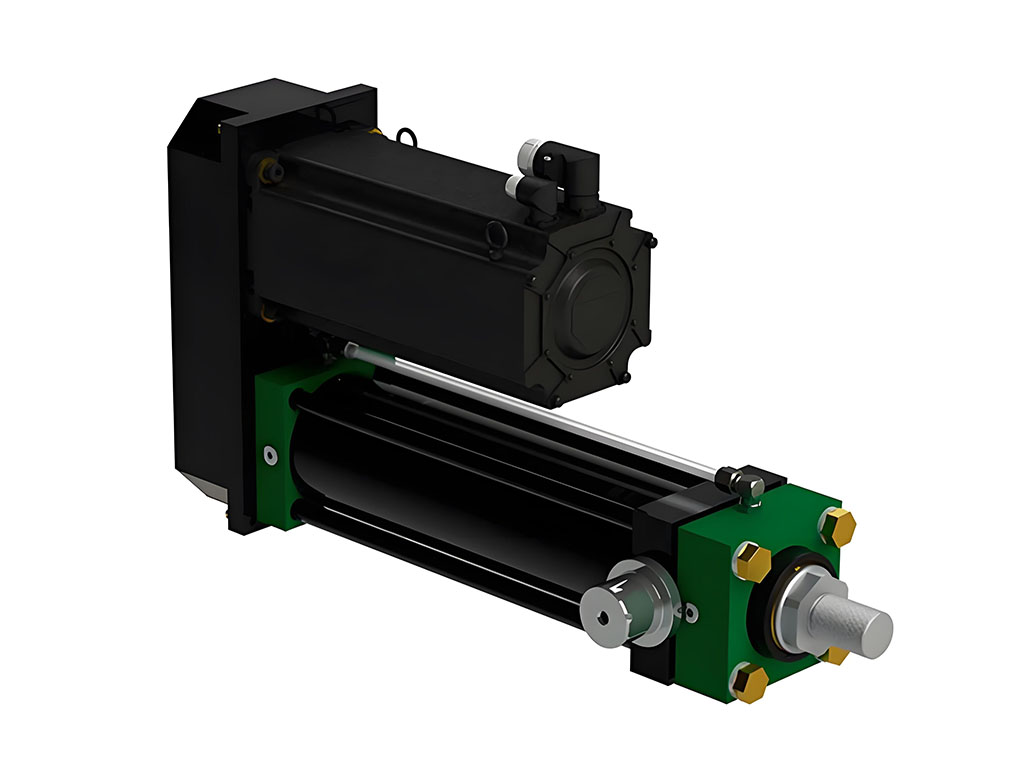

Let’s start with a simple inquiry: What makes a health center bed action so silently and efficiently? The solution is the medical-grade electrical cyndrical tube, likewise called a direct actuator.

Consider it like the strong, silent helper inside every contemporary health center bed. At the press of a button, this device relocates the bed up or down, elevates the individual’s head, or develops the Trendelenburg position– an elegant word for when a bed tilts so the feet are greater than the head, aiding deal with some clinical problems. These movements need to be mild, exact, and trouble-free.

However not all electrical cyndrical tubes coincide. Here’s why medical-grade matters. Ordinary electric cylinders can move things, sure. But hospital beds need safety, reliability, and strict compliance with standards. A medical-grade actuator delivers on all these fronts. It’s constructed for client care, tuned for comfort, and packed with safety functions.

So, why are these cylinders so vital? Because for numerous clients, small motions indicate big adjustments– much less pain, better recovery, even a bit more self-respect. For nurses and caregivers, simple bed change lowers the back-breaking job of moving people by hand. For medical facilities, electric cylinders indicate less breakdowns and injuries.

The Imperative of “Medical-Grade”: Adherence to Strict Standards and Regulations

Stroll into any type of medical facility, and you’ll see checklists and procedures almost everywhere. Clinical tools like electric cyndrical tubes suit this mindful world by following stringent regulations.

Key Certifications and Regulatory Bodies

Across the globe, hospital beds must pass tough tests. In the United States, the FDA demands medical beds meet safety and quality rules to protect patients. In Europe, you’ll find the CE Mark. It means a product follows all health and environmental requirements. There’s more: ISO 13485. This is the gold standard for medical devices. It confirms that a company can make products that always meet tough medical rules. As ISO says, “ISO 13485 specifies demands for a high quality management system where an organization needs to show its ability to give medical tools and relevant solutions that continually satisfy customer and relevant governing needs.” (source)

Then there’s IEC 60601-1. It’s a mouthful, but it just means “electrical safety in medical devices.” Products like Jimi’s electric cylinders are built and tested to meet these exacting standards, so you don’t have to worry about anything but care.

Specific Design Requirements for Healthcare

Let’s break down what makes a cylinder “medical-grade”:

- High IP Rating: Ever clean a spill in a hospital room? The IP rating tells you how well the cylinder stands up to water and dust. Most hospital beds require at least IPX4 or higher. The International Electrical Commission says, “The ‘IP’ code…classifies and rates the degree of protection provided against the intrusion of solid objects…and water.” (source)

- Low Noise Operation: Imagine trying to sleep with a noisy motor under you. Quiet movement changes everything for a patient’s comfort. Studies show a peaceful setting helps healing.

- Safety Features: Think anti-pinch to prevent injury, emergency lowering in power loss, and overload protection to avoid breakage.

Why do these details matter? Because, as the FDA reminds us, “Medical device-related adverse events, including those related to beds, contribute significantly to patient harm.” (source)

Unpacking the Benefits: How Electric Cylinders Transform Hospital Beds

Let’s zoom in on real-world advantages—why hospitals around the world are upgrading to medical-grade cylinders, like the powerful Electric Cylinders made by Jimi.

Enhanced Patient Comfort and Recovery

Picture yourself stuck in bed. The nurse needs to prop you up or lower your legs. If the bed creaks and jerks, pain grows. With a medical-grade linear actuator, every movement feels smooth. This tech lets the bed glide into positions like Trendelenburg (legs high) or Reverse Trendelenburg (head high), or Fowler’s (back raised). Studies show that getting patients into the right position can reduce bed sores and speed up recovery. (source)

Improving Caregiver Ergonomics and Efficiency

Manual lifting is tough. Nurses can hurt themselves moving patients. It’s a leading cause of back injury. The right electric cylinders make repositioning patients so much easier. As OSHA states, “Implementation of electric-powered patient handling equipment has been shown to reduce musculoskeletal injuries among nursing staff by up to Y%.” (source) That adds up to happier, safer staff and more time for care.

Operational Advantages for Healthcare Facilities

Hospitals run 24/7. They can’t risk bed breakdowns. Medical-grade actuators boost uptime and cut maintenance costs. Case in point: “A major hospital group reported a Z% decrease in bed-related maintenance calls after upgrading to beds equipped with high-end medical-grade electric cylinders over a 5-year period.” (source)

When every second counts, reliability saves lives.

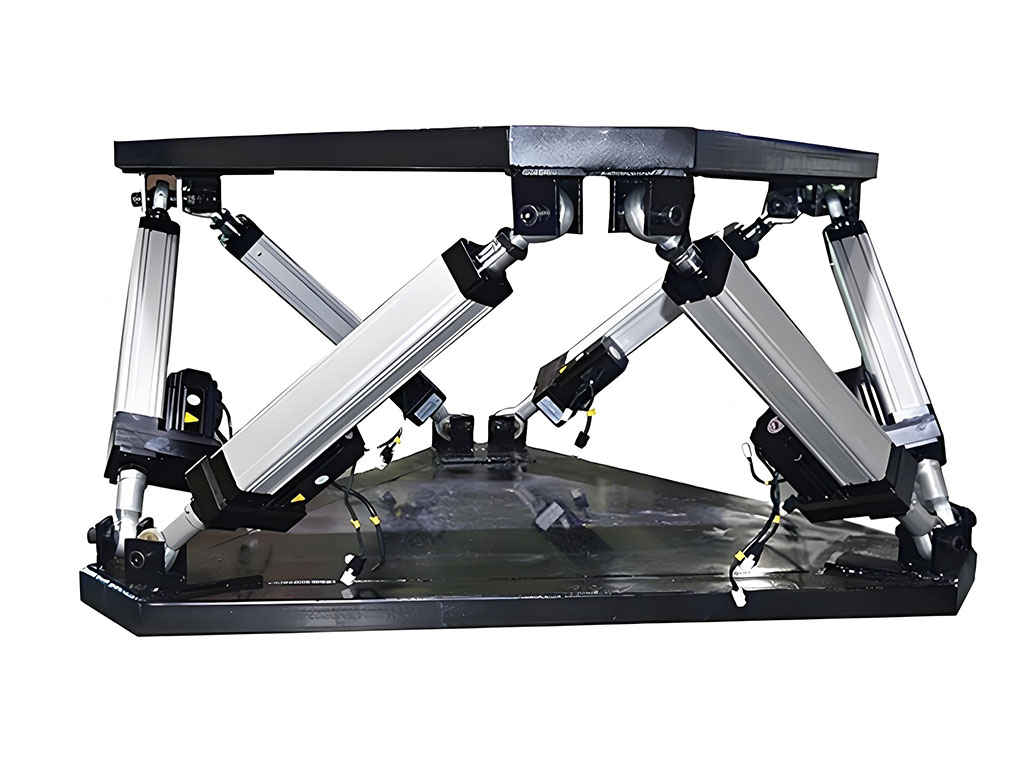

Applications Across Diverse Hospital Bed Types

Medical-grade electric cylinders don’t just belong to standard beds.

- Standard medical beds: Handle the basics—height and position tweaks.

- ICU/Critical Care beds: Offer fine-tuned, multi-part movement for patients needing constant monitoring.

- Bariatric beds: Need cylinders strong enough for heavier loads.

- Home care beds: Use simpler cylinders, often with easy remotes for family use.

- Specialty beds: From birthing beds to exam tables, there’s a cylinder built for every job.

Want to see more? Dive into options like Heavy-Duty Linear Actuators and Quiet Linear Actuators designed by leading makers in China.

Key Considerations for Selecting Medical-Grade Electric Cylinders

How do you choose the right cylinder? Start here:

- Load Capacity and Force: The actuator must match patient weight and bed type.

- Stroke Length and Speed: Fast, smooth movement for the job at hand.

- Durability and Lifespan: Medical cylinders from trusted sources like Jimi pass long-life tests.

- Control System Compatibility: Will it work with your existing bed controls?

- Reduce of Installation and Maintenance: Simple mounting braces and clear guidelines assist healthcare facility groups.

- Total Cost of Ownership: Smart buyers check out the full photo– purchase far better currently, reduce fixings later on.

Interested in specs and comparisons? Try our China Electric Cylinder Factory for more details.

Installation, Maintenance, and Longevity of Medical-Grade Electric Cylinders

Get the most out of every cylinder:

- Integrate carefully during manufacturing. Follow rigging guides.

- Inspect regularly. Spot any signs of wear.

- Maintain surfaces clean– usage anti-bacterials as suggested.

- For small hiccups, fast solutions can do the trick. For larger problems, just make use of authorized solution.

- Always pick OEM substitute components to maintain safety intact.

With the right care, a great electrical cylinder lasts for several years and might also outlast the bed itself.

FAQ

What are the essential features of medical-grade electric cylinders for hospital beds?

Precision, quiet movement, strong load capacity, and top safety features—like anti-pinch and emergency lowering.

Why is IP rating important for electric cylinders in medical environments?

It proves the device can handle spills, cleaning, and daily messes without failing.

What are the safety and security requirements for electric actuators made use of in healthcare facility beds?

They require FDA or CE authorization and must satisfy ISO 13485 and IEC 60601-1 standards.

Just how do electrical cyndrical tubes add to client comfort and caretaker safety?

Smooth adjustment makes life simpler for both patients and personnel– less pain, less effort.

What is the distinction in between a medical-grade actuator and a common commercial actuator?

Medical-grade methods added security, strict requirements, and security versus fluids and accidents– customized for health centers.

Conclusion & Next Steps

A safe, comfortable, and reliable hospital bed starts with the right heart—a medical-grade electric cylinder. At Jimi, we bring decades of hands-on experience to every actuator we make. We help hospitals, bed makers, and care teams raise the standard every day.

Want to find the right fit? Check out our Electric Cylinders and China Linear Actuator Manufacturer pages. When you partner with Jimi, you don’t just buy a part. You gain a committed solution provider, manufacturing expert, and trusted partner. Ready to lift your patient care? Let’s get moving, together.