Imagine trying to fit everything into a crowded room. Every inch matters. Now, think about engineers building machines for factories. It is much the same puzzle but on a much bigger scale. In these busy spaces, even a little extra room can mean adding a faster line, a new tool, or simply making workers’ jobs safer and easier. So, what if one small change could save you space, energy, and time at once? That is where fold-back electric cylinders step in and change everything.

The Hidden Problem: Not Enough Room in Modern Industry

Anywhere you look– factories, laboratories, clean spaces– the tale coincides. Space goes to a premium. Devices do even more in smaller sized footprints. Engineers search for easy ways to pack powerful movement into the tightest spots. Maybe you have run against this wall yourself: There is just not enough room for the equipment your process demands.

Have you ever needed to swap out a big, noisy air cylinder, but the new one just will not fit? Or maybe your team wants to upgrade a production line, but the new technology cannot squeeze into the same place? It happens all the time.

That is why we at Jimi Technology focus on space-saving linear motion—helping you get more function out of less space. The solution? Fold-back electric cylinders that act as the Swiss Army knife for tight installations.

Meet Fold-Back Electric Cylinders: Big Movement, Small Space

What makes these devices so special? It all starts with the unique way they are built.

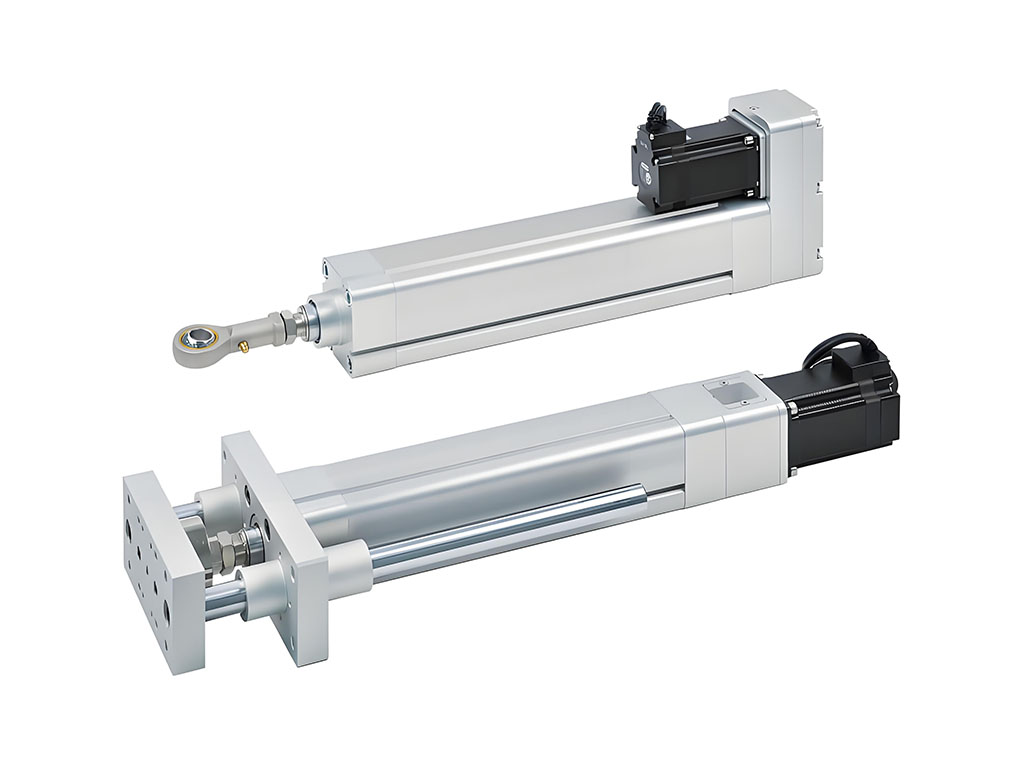

Fold-back electric cylinders flip the script on traditional in-line cylinders. Instead of mounting the motor directly behind the cylinder, the motor sits beside it—parallel to the cylinder body. If you imagine the letter “L,” you have the idea. The clever design turns the rotary power from the motor into straight, back-and-forth movement with the help of a durable belt or gear drive. This setup shrinks the overall length of the device without losing any strength or precision.

Key parts at a glance:

- Integrated motor (servo or stepper)

- High-quality belt or gear drive for turning rotary into linear motion

- Precision ball or lead screw

- Robust internal rod guide and cylinder rod for stability

The end result? You get compact electric actuators with shorter bodies but the same reach, power, and control as much bigger systems.

Want to dive deeper into component choices or how this mechanism works vs. others? Check out our electric linear actuators guide.

Unleashing Real Space: Why Fold-Back Cylinders Win

Let’s lay it out in plain numbers and simple terms.

Traditional electric cylinders stick out straight. They need all the extra length just to make room for the motor. Add the long bodies of hydraulic or pneumatic cylinders, and suddenly you need a lot of precious space just to push a part or lift a box.

Fold-back cylinders offer a better answer. Their “L” shape can make them 30% to 50% shorter than old-school designs. It is type of like folding your legs under the table rather than sticking them straight out– you are still there, yet you occupy less area.

Where does this space matter most?

- On busy production lines—fit more machines or upgrade old stations with no major layout change.

- In small equipment—miniaturize tools for medical, pharmaceutical, or electronics work without giving up function.

- Inside tight robotic cells—add more moves or axes to robots, even when room is scarce.

This new freedom means you can design smarter. Maybe you want to squeeze one more pick-and-place robot into a work cell. Maybe you want to add automatic sorting to a tiny packaging line. With these compact automation solutions, you have room to do it.

Not sure which actuator shape fits your process? Compare traditional and fold-back options in our standard/inline actuators and electric cylinders pages.

More than Just Space: All the Wins Fold-Back Cylinders Deliver

Let us make it clear. Space is only part of the story. These telescopic electric cylinders check boxes that older systems cannot touch.

1. Always Precise, Every Cycle

You set the position. The actuator hits it—every time. With state-of-the-art position control and feedback systems, you get repeatability as tight as ±0.01mm. That means less waste and more productivity.

2. Use Energy, Save Money

Our cylinders work when you need them—no more running compressors or pumps around the clock. Switching from pneumatic cylinders can cut energy use by up to 80%. That’s real money back in your business.

3. Zero Mess, All Clean

No leaks. No oil. No air hoses breaking loose. For cleanrooms, food factories, or labs, that means pure, ISO-rated environments and no downtime for spills.

4. Works Quietly

No loud “woosh” of air or thump of hydraulics. Instead, enjoy up to 20 dB quieter operation. That means a more comfortable workspace.

5. Fewer Problems, Less Downtime

Many thanks to maintenance-free layouts, less moving components, and alternatives like lubrication-free overviews, you invest less time fixing and even more time functioning.

6. Ready for Smart Factories

You can hook them up to all the major control systems—PLCs, HMIs, motion controllers. Add them to your Industry 4.0 automation platforms with no fuss.

Where Every Inch Counts: Industries Changing with Fold-Back Cylinders

You do not have to imagine the impact. Here is where these compact robotic solutions shine in the real world:

- Packaging Machinery—Tight indexing, careful product moves, fast carton sealing—all in smaller frames.

- Medical & Lab Devices—Auto-sample handling and tiny pipetting robots fit inside benchtop machines, even in clean room environments.

- Robotics & Advanced Automation—Design smaller, safer, and more flexible robotic cells or AGVs without bulky actuators.

- Material Handling—Save rows of space in warehouses and logistics centers by shrinking the moving parts.

- Semiconductor Manufacturing—Clean, precise, and space-saving—perfect for wafer handling or testing tools where specs are strict.

- Assembly Automation—Pack more tasks into small workstations. You get faster assembly in tight production cells.

Curious how Jimi’s products fit into your sector? Explore our dedicated solutions for OEM machine design and robotics applications.

What to Check Before Choosing Your Fold-Back Electric Cylinder

Picking the right actuator is key. Here’s a plain checklist to help you nail the choice:

- Stroke Length and Force—How far and how hard does it need to push or pull?

- Speed and Acceleration—Does your process demand quick movement or slow, steady force?

- Accuracy & Repeatability—How exact must each move be?

- Environment—Is it dusty, wet, very hot, or super clean? Look for the right IP rating and material.

- Control System Match—Will it work with your current PLC, HMI, or network (EtherCAT, PROFINET)?

- Mounting Flexibility—Can you fit it in any position or orientation you need?

Need help with the details? Our engineers can help you find or even custom-build the best actuator solutions for your needs.

Proof in Numbers: Why Fold-Back Efficiency Is No Gimmick

Let’s look at real results:

| Metric | Traditional Cylinder | Fold-Back Cylinder | Gain |

|---|---|---|---|

| Footprint | 100% | 50-70% | 30-50% less |

| Energy Use | 100% (pneumatic) | 20-35% (electric) | up to 80% less |

| Maintenance Events | Baseline | 30% of baseline | 70% less |

| Noise Level | Baseline | -20 dB | Much quieter |

| Cleanliness Level | Risk of leaks | Leak-free | ISO Class 3-5 |

A simple switch results in a smaller sized impact, huge energy savings, cleaner lines, and less upkeep. Over five years, this translates into actual dollars saved and more capacity unlocked.

Jimi: Your Partner in Compact, High-Performance Automation

At Jimi Technology, we do more than just sell parts. We craft total services based upon years of experience building portable, durable, and exact movement systems. From mini electrical cyndrical tubes to heavy-duty electric cylinders, we guarantee each product satisfies stringent quality and reliability standards. We believe in backing our engineering quality with real assistance– helping you select, tailor, and incorporate the ideal actuator for your demands.

You can explore our advanced servo linear actuators, compare ball screw actuator options, or browse mounting accessories—all designed for easy system integration.

Space-Efficient Automation: The New Standard

If you are ready to break free from tight spaces, noisy lines, and messy maintenance, it is time for a change. Fold-back electric cylinders deliver space savings while lifting performance in every other way. As more industries aim for smarter, leaner, and cleaner equipment, this is the move that makes the difference.

Ready to reclaim your space—and your productivity? Let Jimi’s experts show you how. Contact us today for advice, product support, or a free consultation. The smarter, smaller, cleaner future is waiting.