Do you want to move something up, down, left, or right with just a button? You need the right tool for the job! At Jimi Technology Co., Ltd., we build amazing automation systems that use both linear motors and electric cylinders. But which one is best for you? Let’s jump in and find out!

One Big Question: Which is Better?

When you build machines for work, science, or fun, you want to get it right. Imagine needing to slide, push, or lift in your robot, packaging line, or medical device. You read, you search, but you keep asking:

“Linear motor vs. electric cylinder—which is better?”

Let's break it down so anyone can see which suits them best.

What is a Linear Motor?

A linear motor is like a magic slider. It turns electricity straight into motion—no gears, screws, or belts in the way!

- No contact parts. Almost nothing wears out over time.

- Super fast and precise. It moves in tiny steps, even smaller than the tip of a pin.

- No sound. It runs quiet as a whisper.

- You find linear motors used in factories, semiconductor equipment, and even for medical tests! Bosch Rexroth, Kollmorgen, and Rockwell Automation use them too.

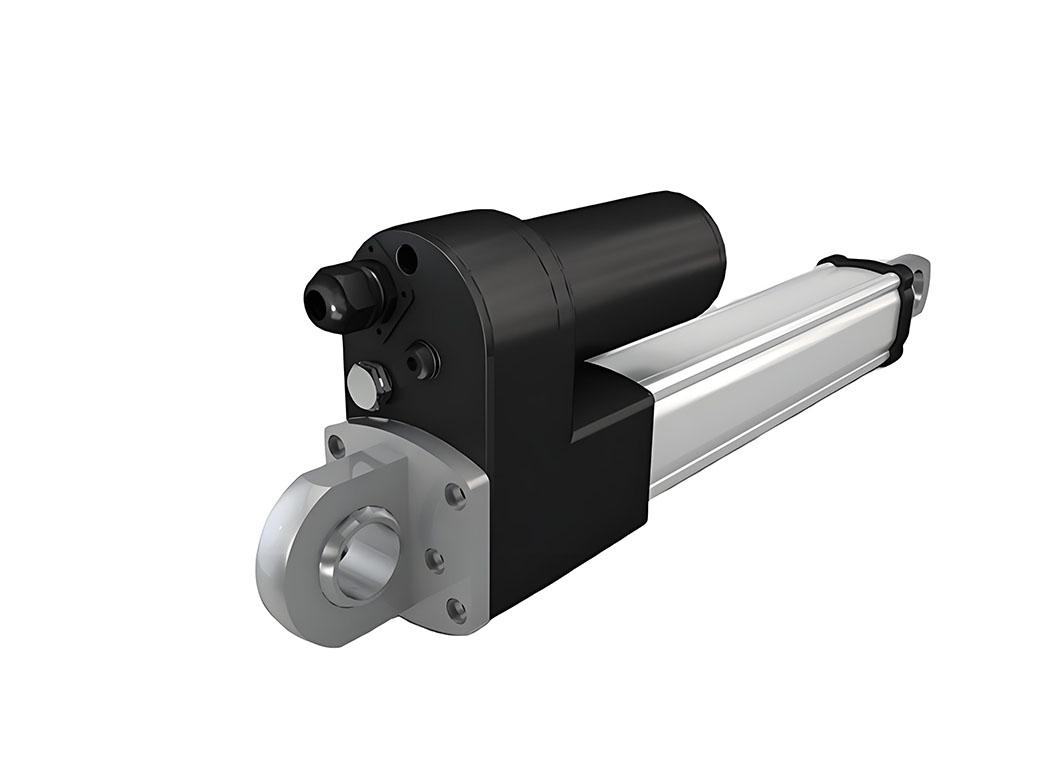

What is an Electric Cylinder?

An electric cylinder is strong and sturdy—think of it as a powerful “robot arm muscle”. It uses a motor to spin a screw, which moves its rod back and forth.

- Amazing force. It can push and pull heavy things with ease.

- Simple, rod-style design. Fits tight places like a glove.

- Needs a bit of care: a little oil here and there; sometimes a new screw.

- Great in assembly automation, clamping, and everywhere you need heavy duty work.

Think of brands like Festo, Siemens, and THK.

Let’s Compare: Table Time!

See what each can do in the chart below:

| Feature | Linear Motor | Electric Cylinder | Why this matters |

|---|---|---|---|

| Precision (Repeatability) | ±0.5 to ±5 µm | ±10 to ±100 µm | Tiny moves for science and fine parts! |

| Max Speed | Up to 10 m/s | Up to 2 m/s | Fast for pick & place, scanning, capping |

| Max Acceleration | Up to 100 G | Up to 2 G | Move quick or strong—choose your hero |

| Continuous Force | 10 to 10,000 N | 500 to 200,000 N | Strong like a superhero |

| Peak Force | Up to 20,000 N | Up to 500,000 N | For big presses and heavy lifting |

| Lifespan (Cycles) | 100 million | 10–50 million | Long life means less fixing! |

| Maintenance | Very Low | Moderate | Save money & headaches |

| Energy Efficiency | 85–95% | 70–85% | Lower power bills = smiles all around |

| Noise Level | <40 dB (like a library) | 50–70 dB (like a conversation) | For classrooms and labs |

| Cleanliness | Excellent | Good | Clean spaces for food, medicine, labs |

What Do You Need?

Let’s talk about your needs. Are you making microchips? Moving food boxes? Lifting tables? Here’s how you solve your problem—the Jimi way.

If You Need:

- Tiny, perfect moves for semiconductor or optics: Go with a linear motor! It’s the king of accuracy.

- Blazing speed? Only a linear motor zooms up to 10 m/s, making it the star in robotics, laser cutting, or picking and placing parts all day.

- Nearly forever life? You’ll love not having to fix, oil, or replace your linear actuators all the time. Linear motors win here.

See our high-speed linear actuators for your next project.

When Do I Pick an Electric Cylinder?

You might say, “But I need to move something heavy. Really heavy!” Or maybe you worry about spending too much. Here’s your answer:

- Pick an electric cylinder for big force jobs—pressing, clamping, or heavy material handling. We build strong industrial electric cylinders that keep going and going.

- Need a small, powerful push in a tight spot? Rod-style electric cylinders fit like a glove.

- Cost-effective startup? Electric cylinders give you more power for your dollar to begin with.

Jimi makes everything from light-duty actuators up to heavy-duty electric cylinders—so you get just what you need!

A Real Story: How Jimi Delivers

Let’s look at a real life win.

The Chip Factory

One customer built chips for phones. Old machines moved too slow and broke too often. What happened when they switched to Jimi’s linear motors?

- They cut the moving time by 30%.

- Accuracy got so tight—just 0.7 microns! That’s way smaller than a human hair.

- No more weekly stops for fixes. Jimi’s parts ran and ran—over 100 million cycles strong.

Heavy Car Parts

A car plant needed to press parts in tight. The old hydraulics were oily and loud. We set them up with our servo electric cylinders:

- Strong presses up to 100,000 newtons

- Much less noise

- Super easy maintenance (just check once a year!)

- Costs cut by 60% because there was no oil mess, no leaks, and simple digital control

Hybrid Power: Best of Both Worlds

Sometimes, you want the perfect mix. Use a linear motor for super fast moves—then pair it with an electric cylinder for strong pressing or locking.

At Jimi, we help you design for speed, strength, and lasting value.

Why Trust Jimi?

Jimi (Jimi Technology Co., Ltd.) isn’t just a brand. We’re the friend who helps you build better. We offer:

- Decades of expertise using servo drives from Parker Hannifin, linear guides from THK, and control systems like Beckhoff Automation.

- Robots, conveyors, medical machines, food packaging, and more—we do it all.

- Customized support: Need feedback devices or motion controllers? We match each customer with the right part and the right know-how.

- We’re not just selling parts—we solve problems for your business.

Easy Steps to Pick the Right Actuator

- Write down what you need: speed, force, precision, space.

- Check our table—see which fits best.

- Ask yourself: “Do I want high speed and low care? Or lots of force and small cost?”

- Visit our China Electric Cylinder Factroy for even more options.

Jimi’s team is always ready to help you choose and design a system that works and lasts.

We Make It Easy

- Cleanroom? Try linear motors!

- Heavy work? Choose electric cylinders!

- Need both? We design hybrid systems!

- See more on our standard/inline actuators page.

Final Thoughts: You Win with Jimi

Linear motors and electric cylinders both have their place.

Linear motors are the master of precision and speed.

Electric cylinders win with power and cost.

Jimi Technology Co., Ltd. stands beside you from start to finish.

You get not just top parts—like those from Bosch Rexroth or Yaskawa—but the wisdom to put them to use.

Need help?

Explore our electric linear actuators or talk with us today.

Let Jimi solve your automation needs—they’re just a click away!

References:

- Bosch Rexroth. "Industrial Linear Motion Guide."

- Semiconductor News, “70% of New Equipment Uses Linear Motors.”

- Automotive Manufacturing Magazine, “Electric Cylinder Case Studies.”

- Jimi Technology Co., Ltd. Automation Solutions Documentation.

Choose Jimi. Move with confidence. Powered by expertise.

Contact us and let’s build your future, one smart move at a time!