曲がるのを見る。止まるのを見る。進むのを見る。.

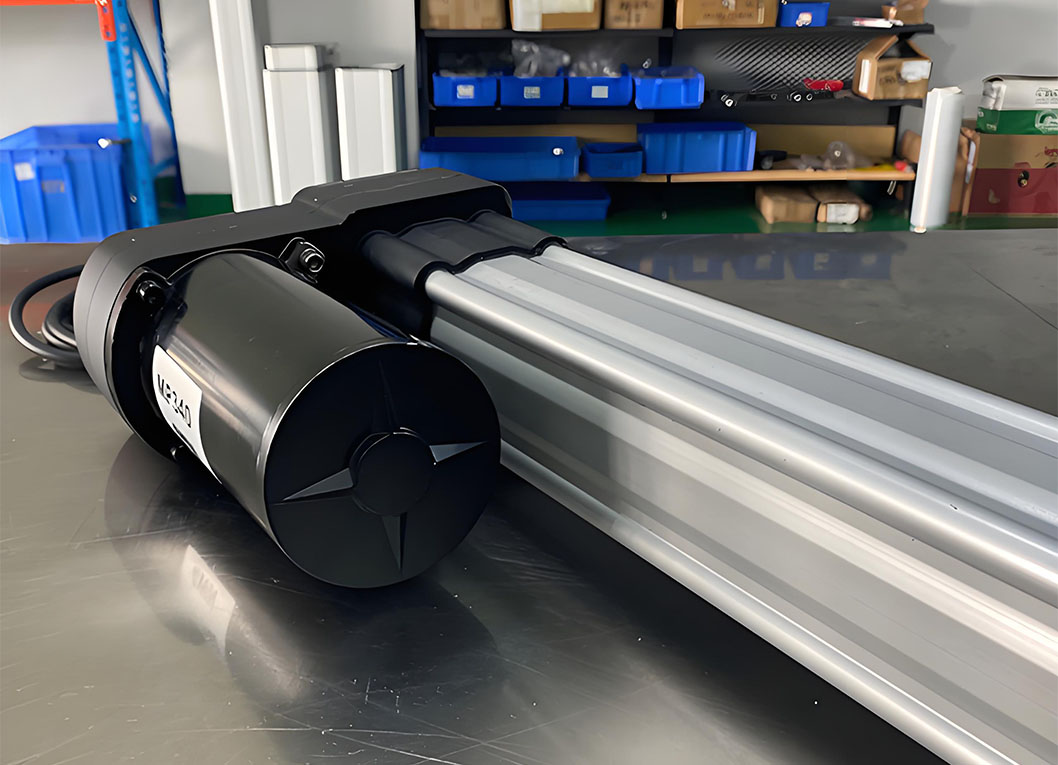

それは ロータリーアクチュエータ 職場で。私はあなたのためにこれを明確にする。私はそれをシンプルにしています。.

I.コントロールされた回転の力

あなたは合図通りに物事が進むことを望む。安全な動きが欲しい。スピードが欲しい。あなたは 精度.

ロータリーアクチュエータは次のような利点があります。 回転運動 信頼できるで回転する。 トルク. .一定の速度で回転する 回転速度. .このセットは 角変位.

私は一日中、動きと向き合っている。正しいツールを選ぶお手伝いをします。私は 自動化システム そして プロセス制御.

II.ロータリーアクチュエータとは?

ロータリーアクチュエータは、エネルギーを回転に変換する。 出力軸. .空気を使うかもしれない。オイルを使うかもしれない。それは 電気モーター.

- あ 空気圧ロータリーアクチュエータ 用途 空圧.

- あ 油圧ロータリーアクチュエータ 用途 油圧.

- アン 電動ロータリーアクチュエータ 用途 でんきでんあつ.

ある者は次のように言う。 限定回転 のようなものだ。 クォーターターンアクチュエーター または マルチターンアクチュエーター. .あるものは 連続回転.

必要に応じて選ぶ トルク出力, 回転角, スピード 電源.

III.どのように機能するのか?

その アクチュエータ動作原理 はシンプルだ。エネルギーは内部の部品を動かす。例えば ピストン, ベンズ, ラック, ピニオン, 歯車、 そして ギアボックス. .この一押しで、.......... 出力軸. .そのターンがマシンを動かす。.

- 空気圧:空気は ピストン・シリンダー機構 または ベーンタイプ ボディ.

- 油圧:流体は同じように作用するが、より多くを与える 送電 そして高い トルク.

- 電気:モーターで駆動する ギア駆動アクチュエータ または リンク機構アクチュエータ. .ACでもDCでもいい。また サーボロータリーアクチュエーター または ステッピングロータリーアクチュエーター.

を追加することができる。 ポジションフィードバック と 位置センサー そして リミットスイッチ. .を追加することができる。 制御信号 より PLC (プログラマブルロジックコントローラ) または HMI(ヒューマン・マシン・インターフェース) または SCADA(監視制御およびデータ収集). .を使用することができます。 電磁弁 を使って空気を入れ替える。あなたは 制御システム ガイド 角速度 そして好きなところで止まる。.

IV.主な種類

- 空気圧ロータリーアクチュエータ

- ラック&ピニオンアクチュエーター: a ピストン を動かす。 ラック。その ラック を回す。 ピニオン.

- ベーンタイプアクチュエーターエアプッシュ ベンズ のために 角変位.

- フィットする バルブオートメーション そして 軽い荷物. .それは 費用対効果.

- 油圧ロータリーアクチュエータ

- ラック&ピニオン, ベーン、 または スコッチヨークアクチュエーター.

- それは、高いパフォーマンスを提供する。 トルク そして 堅牢 アクションにフィットする 重荷.

- 電動ロータリーアクチュエータ

- モーター駆動 交流, DC, サーボモーター、 または ステッピングモーター.

- それは次のようなものだ。 正確なポジショニング そしてスマートなコントロール。それは エネルギー効率 多くの仕事で。.

- 義務スタイル

- 複動アクチュエータ

- スプリング・リターン・アクチュエータ

- 1/4回転アクチュエータ そして マルチターンアクチュエーター

V.主要部品

- 入力ポートまたは 電気接続

- シリンダー または住宅

- ピストン, ベーン、 または モーター

- ラック&ピニオン または 歯車機構

- 出力軸

- シール そして ベアリング

- ポジション指標 そして センサー統合

VI.どのように使われているのか?

ロータリーアクチュエータは様々なところで目にします。明確な使用例をお見せします。.

- バルブオートメーション

- クォーターターンバルブ ような ボールバルブ, バタフライバルブ、 そして プラグバルブ.

- の流れをコントロールする。 プロセスプラントオートメーション.

- で見つけることができる。 石油・ガス用アクチュエータ, 化学処理用アクチュエータ, 廃水処理アクチュエータ, 食品・飲料産業用アクチュエータ、 そして 製薬用アクチュエータ.

- また、こうも見える。 1/4回転バルブアクチュエータ, ボールバルブアクチュエーター, バタフライバルブアクチュエーター、 そして プラグバルブアクチュエーター のセットだ。.

- 産業機械および製造業

- ロボット工学アプリケーション そして 産業用ロボット 使用 ロボットグリッパー回転, 索引表、 そして 手首 が動く。.

- マテリアルハンドリング機器 用途 クランプ機構, 傾斜メカニズム、 そして 回転治具.

- 包装機械 そして 包装機械 キャップやラベルに使う。.

- 組立ラインの自動化 そして 組立ライン そして ベルトコンベヤー ターン&プレイスが必要だ。.

- 産業機械の動き シンプルで力強いターンが好きだ。.

- エネルギーと公益事業

- 発電用アクチュエーター のために タービン そして ダンパーコントロール.

- HVACシステムアクチュエータ のために ダンパー そして ファーネス・ダンパー・アクチュエーター.

- オーブンドアアクチュエーター 熱いドアを開け閉めする。.

- 大きな畑

- 航空宇宙用アクチュエーション そして ディフェンス フラップとギア用。.

- 医療機器の作動 研究室やベッドで.

- マリンアプリケーション そして オフショアプラットフォーム機器 過酷な海のために。.

- 鉱山機械用アクチュエータ, 自動車産業用アクチュエータ, 農業機械用アクチュエータ, 繊維機械用アクチュエータ, 印刷機用アクチュエータ、 そして 半導体製造用アクチュエータ タイトなターンが必要だ。.

VII.ロータリーアクチュエータを選ぶ理由

あなたが望む 自動化と効率化. .手作業を減らしたい。あなたは 高速応答アクチュエータ.

あなたが望む 精度とコントロール のために 正確なポジショニング.

あなたが望む 安全機能 アクチュエーター 人々の安全を守るために。.

あなたが望む 多用途 多くの仕事のために。.

あなたが望む 耐久性のあるアクチュエータ そして 信頼性の高いアクチュエータソリューション 過酷な現場のために。.

あなたが望む アクチュエータのエネルギー効率 そして コンパクト設計アクチュエータ スペースが限られているところ.

VIII.選ぶ前にチェックすべきこと

- 応募条件: トルク, スピード, アングル、, 精度

- 電源供給空気、液体、電気

- 環境条件熱、ほこり、スプレー、, 腐食剤, 防爆アクチュエータ

- 管理要件オン・オフ、比例, フィードバック

- アクチュエータの性能指標 そして 回転アクチュエータのコスト

- アクチュエータの設置, アクチュエータのメンテナンス、 そして アクチュエータのトラブルシューティング

- IP定格アクチュエータ IP65またはIP67の防水・防塵構造

- ATEX指令 ゾーンと API 6D そして ISO 5211 バルブ用フランジ

を使用する。 回転アクチュエータサイズ計算機 を取得する。 トルク出力. .スマート アクチュエータ設計の考慮点 リスクを避けるためだ。.

IX.ロータリーとリニア:最適なモーションを選ぶ

仕事によっては 回転運動. .ロータリーアクチュエータを使用する。.

仕事によっては押したり引いたりする必要がある。その場合は リニアアクチュエータ.

私は明確なヘルプでリードする。私のチームは ジミ(ジミテクノロジー株式会社) 作る 高品質のリニアアクチュエータ, テレビリフト、 そして 自動化システム. .私たちの製品は electrical energy に 直線運動. .あなたが上げる。下げる。押す。引っ張る。傾ける。タッチでやる。私は単なる売り手ではない。私は エキスパート, a ソリューションプロバイダそして 信頼できる権威 この分野で.

リニアが必要な場合は、適切なユニットを迅速にご案内します。当社の全製品を見る 電動リニアアクチュエータ クリーンでスマートな電力のために: 高性能電動リニアアクチュエータ.

あなたの仕事に必要なもの 正確なポジショニング スマートなループで、私はあなたを助ける サーボモーターアクチュエータ そしてタイトな動き: 精密位置決め用サーボモーターリニアアクチュエーター.

工場や機械を作るなら、私はフルスタックでサポートする。 産業オートメーションアクチュエータ: 産業用オートメーション アクチュエーター・ソリューション.

確かなフィードバックをお望みなら、私にお任せください。 位置フィードバック付きアクチュエータ 簡単に HMI そして PLC リンク クローズドループ制御のための位置フィードバック付きリニアアクチュエータ.

また、リニアとロータリーを1つのクリーンに融合させる手助けもする。 メカトロニクス 計画私は 制御システム をリンクしている。 PLC、その HMI、その SCADA, そしてあなたのフィールド バルブアクチュエータ. .さらに 位置センサー そして リミットスイッチ.私は 電磁弁 空気のために。私は ギアボックス ドライブで。私はあなたのラインを時計仕掛けのように動かす。.

X.クイック比較表

| タイプ | パワー | 標準トルク | アングル | 最適な用途 | 注記 |

|---|---|---|---|---|---|

| 空気圧ラック&ピニオン | 空気 | ミディアム | 90°から180 | バルブオートメーション | シンプルで速い |

| 空気式ベーン | 空気 | 低~中 | 0°~270 | ライトツール | コンパクト |

| 油圧ラック&ピニオン | オイル | 高い | 90°~マルチターン | 重機 | ハイフォース |

| 油圧スコッチヨーク | オイル | 非常に高い | 90° | 大型バルブ | 強力な逃げ切り |

| 電動サーボ | 電気 | 低から高 | どんなものでも | ロボット工学と正確な位置決め | プログラム可能 |

| 電動ステッパー | 電気 | 低~中 | インデックス付きステップ | インデックス・テーブル | 低コスト |

チューニングできる 角速度 そして 回転速度 バルブサイズ別、またはドライブセット別。サイズ 複動アクチュエータ または スプリングリターン・アクチュエータ フェイルセーフのため。.

XI.トルクレンジの簡単な「チャート」表示

- Electric stepper: ███

- Electric servo: ███████

- Pneumatic rack and pinion: █████

- 油圧ラック&ピニオン

- 油圧スコッチヨーク

バーが増えるということは トルク出力.

XIIブランド、基準、信頼

私は現場を知っている。スペックも読む。ギアをテストする。私は次のようなリーダーたちのデータを使って仕事をしている。 フェスト, パーカー・ハネフィン, SMC株式会社, ロトルク, ノルグレン, ジーメンス, ボッシュ・レックスロス, ビンバ・マニュファクチャリング, フローサーブ, AUMA、 そして エマーソン.私は次のように調整する。 ISO 5211 マウントルール私は ATEX指令 リスクゾーンでサイズ API 6D のために クォーターターンバルブ.

私はチェックする IP定格アクチュエータ ウォッシュダウンのために。マッチ ダンパー で 空調. .私はフィットする コンベヤーシステム そして マテリアルハンドリング フレーム私は 自動化システム でクリーンに走る。 組立ライン そして 包装機械.

XIII.コスト、ケア、アップタイム

私は 回転アクチュエータのコスト ニーズに合わせて私はクリーンな計画を立てる アクチュエータの設置. .私は簡単に設定した。 アクチュエータのメンテナンス. .私は書く アクチュエータのトラブルシューティング クルーが使えるステップ.

Iログ アクチュエータ性能測定基準 そうすれば改善できる。私は、次のような点に注意している。 シール そして ベアリング.私はチェックする ピストン, シリンダー, ベンズ, ピニオン、 そして ギアドライブ フィットしている。.

XIV.あなたの必要性と私の約束

- 注目を集める

スムーズなターン。今すぐにでも。.

- 必要性を指摘する

ラインは時間を守らなければならない。工場は安全でなければならない。バルブは時間通りに閉まらなければならない。.

- ニーズを満たす

サイズ ニューマチック, 水理、 または エレクトリック ロータリーユニット私はスマートな ポジションフィードバック. .あなたの PLC, HMI、 そして SCADA.

- 製品の位置づけ

ストレートなプッシュ&プルが必要なときは、ジミを投入する。 リニアアクチュエータ. .ロータリーセットとの相性もいい。持ち上げる。下げる。押す。引く。傾ける。ボタンひとつでできる。.

私の実績を見てほしい 電動リニアアクチュエータ 今すぐ私の サーボモーターアクチュエータ トップコントロールのために。私の 産業オートメーションアクチュエータ を使用しています。私の 位置フィードバック付きアクチュエータ タイトなループのために。私は、あなたが計画から実行に移すのを助ける。.

XV.今後の動向

なるほど スマートアクチュエータ そして IoT リンクなるほど 小型化. .もっと見る エネルギー効率. .とのより緊密なリンクが見える。 メカトロニクス そして 制御システム.

私は今、あなたに最高のフィット感をもたらす。次に何が起こるかわからない。.

参考文献

- ロトルクバルブ作動の基本.2025年取得。.

- エマソンアクチュエータ選択ガイド.Retrieved 2025.

- ISO 5211.工業用バルブ-パートターン式操作部アタッチメント。最新版。.

- API 6D.パイプライン及び配管用バルブの仕様書。最新版。.

- ATEX指令 2014/34/EU。爆発性雰囲気用機器。.

- Festo, Parker Hannifin, SMC Corporation, Bosch Rexroth, Flowserve, AUMA.空圧、油圧、電動アクチュエータの製品データシート。.

- シーメンスとノルグレンの制御と空気圧のアプリケーションノート。2025年取得。.

まとめ

ロータリーアクチュエータとは何か、お分かりいただけただろうか。回転アクチュエーターがどのようなものか。そして ロータリーアクチュエータの種類. .キーポイント ロータリーアクチュエータの用途.

自信を持って選ぶことができる。慎重に計画を立てることができる。今すぐ行動できる。.

私は助けるためにここにいる。私は 経験, 専門知識, 権威性、 そして 信用性. .私はアイデアから立ち上げまで、あなたの側にいます。私はあなたを動かし続けます。.