The Dawn of Smart Production: Why Industry 4.0 Needs Advanced Motion Control

Picture a factory floor filled with devices talking to each various other, all interacting without time out. Everything moves like clockwork. Decisions happen in a fraction of a second. This is not just a desire. It is the fact of Industry 4.0. Today, clever manufacturing links equipments, collects data, and utilizes automation for far better results. Assembly line have actually come to be living, believing systems.

Why does this issue? The world is scooting. Companies need to make items quicker, more affordable, and much better. Standard makers, like old compressed air cylinders, battle to keep up. They lack minds. They consume lots of power and can not inform you when something is incorrect. Factories require devices that are quicker and smarter.

That is where servo cylinders been available in. They are the whipping heart of modern motion control. Servo cyndrical tubes bring minds, muscle, and rate to manufacturing. They assist make factories cleaner, much safer, and smarter.

Unpacking Servo Cylinders: The Intelligent Actuators for Digital Factories

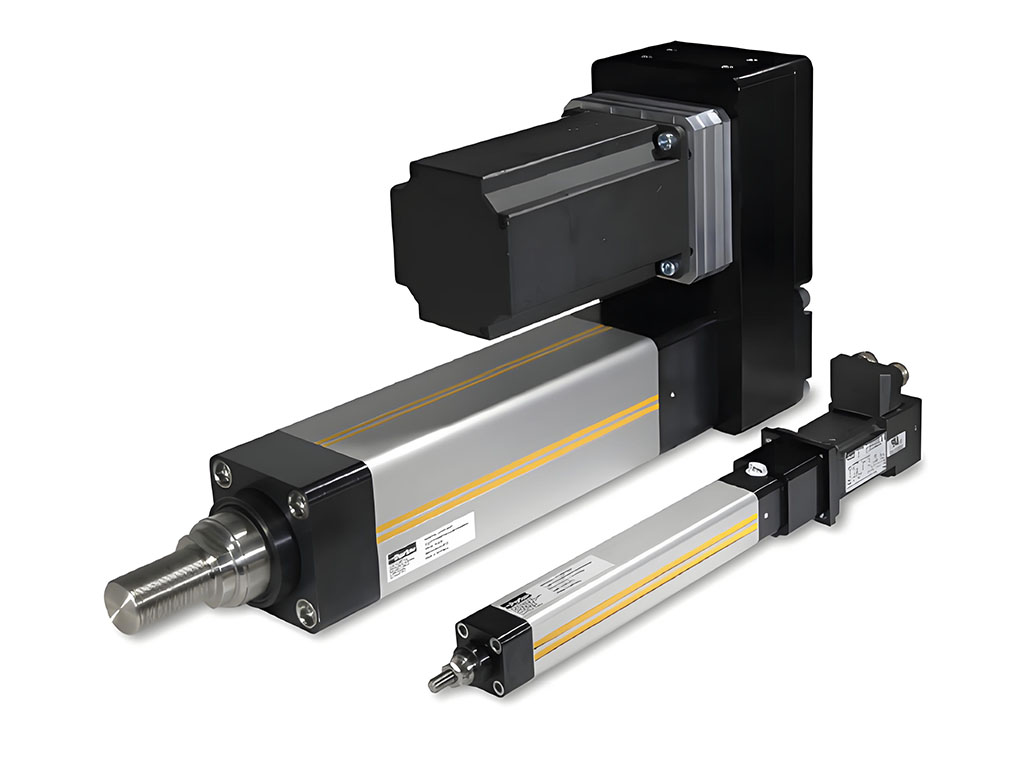

So, what is a servo cylinder? It is a powerhouse built from three things:

- A linear actuator

- A servo motor

- An encoder with a drive

Put together, these parts create precise movement. You press a button. The servo cyndrical tube pushes, pulls, or raises exactly the correct amount– no more, no less. It can duplicate this job thousands of times, never ever getting tired. It tracks its own position, speed, and force. You get total control.

Servo vs. Traditional: A Performance Showdown for Smart Lines

Let’s stack up servo cylinders against older options:

| Feature | Servo Cylinders | Pneumatic/Hydraulic Cylinders |

|---|---|---|

| Precision | Micrometer accuracy [Bosch Rexroth – Servo Actuators Guide] | Low—hard to control |

| Energy Use | 80–90% efficient [Festo – Energy Efficiency] | 10–25% efficient |

| Cleanliness | No leaks or oil | Oil leaks, mess |

| Noise | Quiet | Loud, can be distracting |

| Data & Control | Smart feedback | Minimal |

| Maintenance | Long intervals | Frequent, downtime is high |

In most smart factories, servo cylinders win hands down. They save energy, deliver accuracy, and do not make a mess. They even collect data as they work. That data can flag problems before they cause a shutdown.

Key Features Defining a Smart Servo Cylinder

Here’s why servo cylinders are the stars of the show:

- Closed-loop control: Constant feedback keeps operation tight and safe.

- Programmability: Adapt to any task, big or small.

- Multiple positions: Hit every point on your line, not just “push” or “pull.”

- Built-in intelligence: They spot wear, drift, or overload before disaster strikes.

Servo Cylinders as Catalysts for Smart Production Lines

In Industry 4.0, information is gold. Servo cylinders collect it at the ground level—right where things happen.

- Data acquisition: Temperature, current, rate, position, and pressure– all tracked and sent to the system.

- Analytics-ready: This information heads to the cloud or a programmable logic controller (PLC).

Smart servo cylinders ramp up Overall Equipment Effectiveness (OEE). They spot jams and wear early. You move from fixing problems after they happen to stopping them before they start.

Powering Predictive Maintenance & Condition Monitoring

With anticipating upkeep, you do not wait on machines to stop working. Instead, servo cylinders warn you with real-time data. For instance, a sudden rise in temperature might mean a worn bearing. The system can tell you exactly what is wrong and even schedule a service.

Installing predictive systems with smart servo cylinders can cut unplanned downtime by up to 50% [Deloitte – The Future of Manufacturing]. You produce more, waste less, and stress less.

Enabling Digital Twin Integration and Simulation

A digital twin is a virtual copy of your production line. It mirrors every move your actual equipment makes. Real-time data from servo cylinders helps fuel this model. You can test changes, plan upgrades, or tweak settings—all without touching a real machine.

Plants using digital twins see 10–15% better product quality and efficiency [Gartner – Predicts 2023: Digital Twin Adoption]. Servo cylinders make this possible.

Tangible Benefits & Real-World Applications

Precision & Quality Redefined

Servo systems can guide parts down to micrometers. For example, in electronics manufacturing, even a small mistake ruins a product. Servo cylinders ensure tight assembly, low scrap, and repeatable results every time.

They shine in:

- Automated assembly

- Sensitive testing labs

- Press forming operations

Unlocking Energy Efficiency & Cost Savings

Switching from air to electronic power is not just smart—it pays for itself. Electric servo actuators can reach 80–90% energy efficiency, while air systems waste up to 90% [Festo – Energy Efficiency].

Case in point: a packaging line swapped pneumatic actuators for servo cylinders. Throughput jumped 15%, and energy bills dropped by 25%, paying back the investment in just 18 months [Schneider Electric – Case Study: Smart Packaging].

Boosting Productivity & Flexibility

Want to run different products without reworking your line? Servo cylinders can do that. Their quick-change programming means faster switches and no long pauses. Productivity surges. You can see it in industries such as automotive, food product packaging, and electronics.

Explore more use cases for Electric Linear Actuators and Industrial Automation Actuators.

Overcoming Implementation Challenges & Glimpsing the Future

Nothing good comes easy. Here’s what to plan for:

- Upfront investment: Servo tech costs more at the start but pays back fast through lower bills and less waste.

- Training: Staff need to learn new tricks—but the skills pay dividends.

- Integration: Servo cylinders fit most production lines, but a solid plan safeguards a smooth transition.

The Road Ahead: Evolution of Servo Technology in Industry 4.0

Servo cylinders are evolving too. They are getting smarter, smaller, and more connected. AI and artificial intelligence drive automated adjustments– no human required. Quickly, they will certainly play a vital function in autonomous robots and collaborative systems. Envision makers that pick up when something is off and repair it on their own!

Industry 4.0 is growing at over 17% a year and will hit USD 530 billion by 2026 [ReportLinker – Industry 4.0 Market Report]. Want to be left behind? We did not think so.

Frequently Asked Questions (FAQ)

Just how do servo cyndrical tubes add to Industry 4.0?

They offer exact, programmable activity and come to be vital data factors in a smart factory. This details helps you area inefficiency quickly and repair it.

What are the main advantages of electric servo cylinders over pneumatic ones in smart factories?

Efficiency and control. Electric servos are 3–4 times more energy-efficient and offer pinpoint accuracy, while air cylinders waste energy and lack feedback.

What are the primary benefits of electric servo cylinders over pneumatic ones in clever factories?

Effectiveness and control. Electric servos are 3– 4 times more energy-efficient and deal identify precision, while air cyndrical tubes waste energy and absence comments.

What specific data can servo cylinders provide for analytics in Industry 4.0?

They offer you details like setting, force, speed, existing, temperature level, and cycle counts. All this information feeds into IIoT and diagnostic platforms.

How do servo cylinders improve energy efficiency in manufacturing?

They need less power to run and can turn off totally when not functioning, unlike air-driven systems that have to stay under pressure.

Conclusion & Next Steps

Servo cylinders are not just machine parts—they are the engines powering Industry 4.0. They pack precision, speed, and intelligence. They turn raw factory floors into smart, connected, and future-ready arenas.

At Jimi, we do not just sell servo cylinders; we deliver answers. With decades of know-how, robust designs, and a focus on your needs, we help you unlock new levels of performance. From selecting the right Servo Linear Actuators to integrating Industrial Linear Actuators and expert Actuator Controllers, we stand by you every step.

Ready to see how servo cylinders can transform your production line? Contact our experts for a tailored consultation or download our guide to selecting the right servo cylinder. The future is smart, and with Jimi, you are always a step ahead.