The Evolution of Wind Turbine Control Equipment

Think of a field loaded with high wind turbines, all turning silently in the wind. Every second, each one needs to adjust itself. It changes the angle of its giant blades or turns to face the wind just right. Years ago, these huge machines used oil and pumps—hydraulics—to move. That worked, but not for long.

From Hydraulic Reliance to Electromechanical Precision

Hydraulic systems use pumps and oil to move things. Sure, they push hard, but they can leak. Sometimes, the pipes break. Changing oil gets messy and costs money. In cold places, oil gets thick and slows down. In hot places, it breaks down. Plus, if oil spills in the sea, that’s pollution. Everyone hates leaks.

Here comes a change: electric cylinders. These tough machines use electric power, not oil. They act fast. They don’t leak. They don’t mind the cold. No more changing oil. No more mess.

The Critical Role of Actuators in Turbine Performance

But why do we care about these actuators? Simple. They turn the blades. We call this pitch control. When turbines find strong wind, the blades must lean into the wind or turn away for safety. That saves the machine from damage and helps it make more electricity.

Then, there’s yaw control. This means the huge box, the nacelle, on top twists to follow the wind, just like how you turn your head toward a sound. Get this wrong, and you lose power. Get it right, you catch every bit of wind.

What Are High-Load Electric Cylinders?

Defining High-Force Linear Actuators for Industrial Use

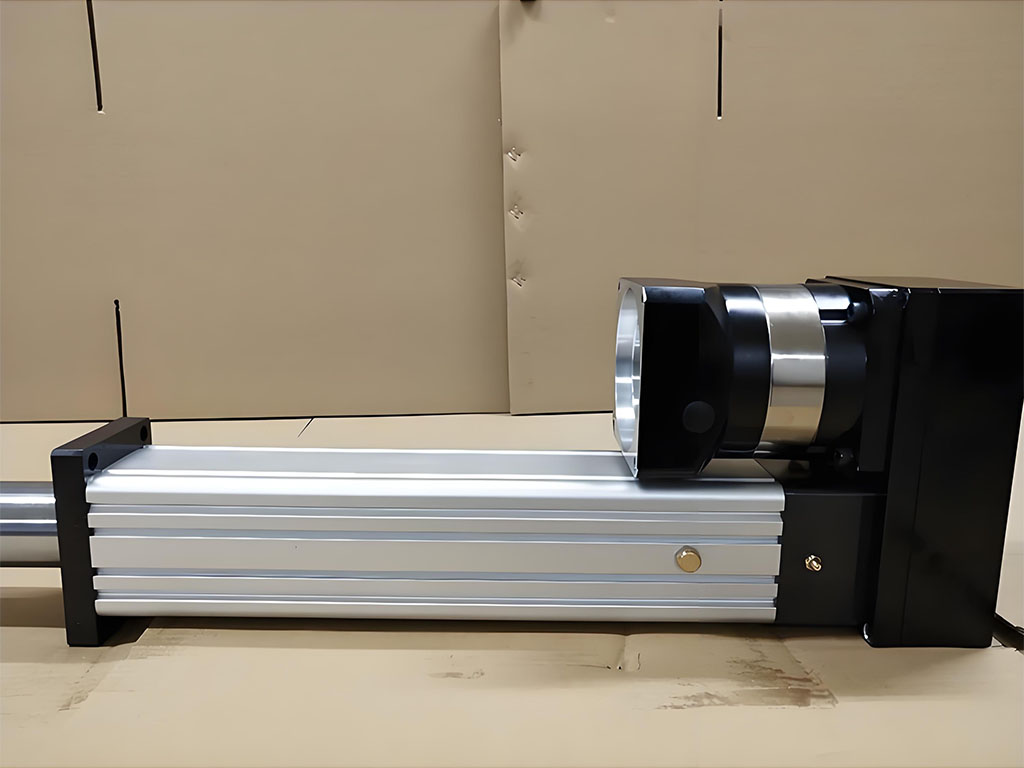

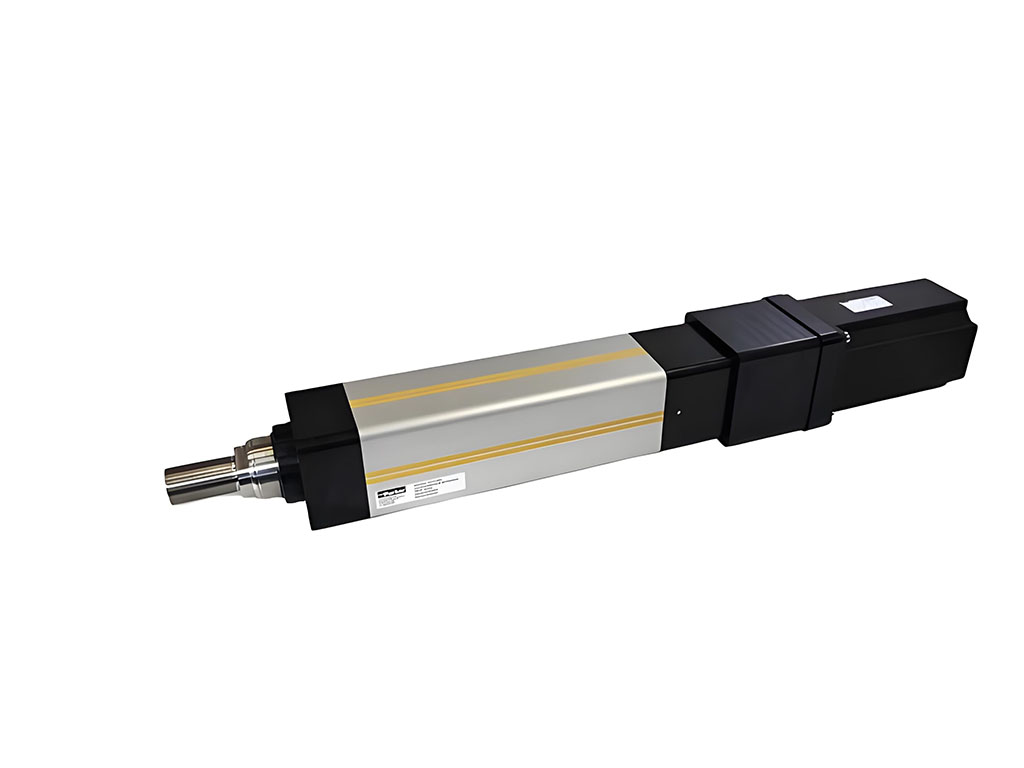

So what is a high-load electric cylinder? Consider it like an arm with large muscle mass. Inside, you’ll discover an electric motor, gearbox, a special screw, and a tough overview. The electric motor rotates, the screw turns, and the arm presses or pulls extremely hard. These machines work for days and nights without stopping. Some can move as fast as a rabbit, others as slow and steady as a turtle—there’s one for every job.

The word “high-load” means these cylinders don’t stop at small tasks. They can push or pull with huge force—up to 30 tons or more. That’s like lifting five elephants in one go!

How Electric Cylinders Function in Wind Turbine Applications

Inside a wind turbine, the high-load cylinder shifts a big pin. This pin tilts the blade—pitch control. Or the cylinder twists the top—yaw control. These jobs need both brawn and smarts. Electric cylinders connect straight to the turbine’s brain: a control box called a PLC or SCADA system. A computer tells the cylinder exactly what to do and when to move.

Everything happens at the push of a button—or, really, a signal from the control system. Quick moves mean the turbine stays safe from storms and can make more power in quiet winds.

Unrivaled Advantages: Why Electric Cylinders Are Superior for Wind Turbines

Let’s make this simple. Why do experts pick electric cylinders now?

Improved Energy Efficiency and Reduced Operational Costs

Electric pitch systems can save 20-30% on power contrasted to hydraulics (SKF Whitepaper, 2023). That’s massive. Why? No requirement for large pumps running continuous. No more buying oil, paying individuals to alter it, or repairing leakages.

Superior Precision, Control, and Responsiveness

With electronic control, electric cylinders struck the appropriate spot every single time. If one blade requires to move a little bit, it does– quick. Extra control means a lot more power out, even more stability for the grid, and less endure components. Required evidence? A wind ranch in Europe changed to electric pitch and saw power go up, downtime drop (DNV GL report, 2022).

Reduced Maintenance and Increased Reliability

Electric cyndrical tubes have less moving components, and they operate in sealed systems. That means you don’t have to stop to fix leaks or change out old parts as often. In some studies, turbines with electric actuators saw up to a 70% drop in maintenance costs across their lives (“Wind Turbine Actuators Report,” Allied Market Research, 2023).

Environmental Benefits and Safety Improvements

No oil means no spills. No spills mean you protect land and sea. Only clean, quiet work, even out in the ocean. There’s also much less risk of fires. For ports and offshore wind farms—where spills can ruin everything—this is a huge relief.

Advanced Monitoring and Predictive Capabilities

Modern electric cylinders come with smart sensors, so you can watch how your equipment is doing. A quick check finds problems early. The brains in the turbine predict issues before they stop your work. That keeps the turbines spinning.

Key Applications and Implementation in Wind Turbines

Precision Pitch Control Systems

Getting the blade angle right is key. If the blades point wrong, the turbine might break or produce less power. High-load electric cylinders help the blades twist quickly when the wind gets wild. They assist with an emergency stop, too.

Automated Yaw Alignment

Wind never stands still. The turbine must face it just right. Electric cylinders let the top box turn with the breeze. This gives the best chance to catch every gust. It even reduces stress on the tower and blades, helping them last longer.

Other Potential Applications

Electric actuators also help with things like braking (stopping the turbine) and controlling how smooth the ride is (active damping), even in very rough storms.

Technical Considerations and Selection Criteria

Picking the right electric cylinder isn’t magic. You need to check:

- Force needed (how hard it must push or pull)

- Speed (how fast)

- Stroke (how far it travels)

- Duty cycle (how often it works)

- IP rating (how tough it is against dirt, water)

- Temperature limits

- Will it fit your PLC or SCADA (the control brain)?

Retrofit? Many companies now switch old hydraulic lines to new electric systems without big changes. Some smart solutions help you do this quickly.

They must also survive tough places: salt air, dirty dust, freezing cold, boiling heat, and wild shaking. Every Jimi actuator, for example, comes tested for all these.

The Future of Wind Energy: Electrification and Smart Control

Industry Trends and Market Growth for Electric Actuators

You might wonder, is this just a new trend? Not at all. Global wind power keeps growing fast. Turbines keep getting bigger. Old hydraulics can’t keep up. Electric cylinders are grabbing more of the market each year, pushed by new rules and a demand for cleaner energy (Global Wind Energy Council, 2023).

Innovations in Electric Cylinder Technology

New features keep arriving. AI, IoT, and digital twins—a kind of computer “mirror” of each machine—help people watch and steer turbines from far away. Jimi Technology always keeps our electric cylinders ready for these tools, keeping you one step ahead.

Choosing the Right Partner: Leading Manufacturers and Solutions

Not every actuator works for wind power. You want a partner who gets it. The big names—SKF, Bosch Rexroth, Moog—each offer their specialties. But when you seek the right blend of custom design, reliability, and know-how, you want Jimi.

At Jimi Technology, we’re not just a electric cylinder seller. We make the engines, the screws, every part. We test them until they pass even the hardest checks—IP ratings for water, salt, and sand, cold and heat tests, shock and vibration.

Need a heavy-duty linear actuator for a giant turbine? Done. Need electric cylinders that fit your PLC? No problem. Want servo linear actuators for smart, fast moves? Order today. You can even customize the biggest models, 250 Series—all factory direct.

Here’s how we stack up in key specs:

| Jimi Series Example | Max Force (tons) | Max Stroke (mm) | Duty Cycle | IP Rating |

|---|---|---|---|---|

| 250 Series Custom | 30T | 1500 | 100% | IP66 |

| 190 Series High Load | 20T | 1200 | 80% | IP67 |

| 110 Series Heavy Duty | 15T | 1000 | 60% | IP66 |

Paving the Way for Sustainable and Efficient Wind Power

Electric cylinders are changing the wind industry, one strong push at a time. The move from old hydraulics to new, precise actuators means more power, less downtime, and a cleaner world.

We at Jimi see firsthand how these smart, strong tools lower costs and raise uptime. We help wind farms make more energy and protect our planet. If you’re ready to upgrade your wind project, there’s no better partner. Bring your big challenges. We’ll help you move them, one cylinder at a time.

Explore more about our electric linear actuators, industrial automation actuators, and see why so many global wind leaders trust Jimi. Let’s build the future of clean, efficient, reliable wind power—together.