You want smooth motion. You want small size. You want big power. I get it.

I help you build fast, safe, smart machines. I make motion simple. I make motion right.

I am Jimi Technology Co., Ltd. I lead in linear actuators, TV lifts, and automation systems. My gear turns electric power into straight motion. You press a button. Things raise, lower, push, pull, or tilt. I am not just a seller. I am an expert. I am a solution provider. I am a trusted authority. You can count on me.

What is a frameless motor?

- It is two parts. A stator and a rotor.

- No case. No shaft. No bearings.

- You put it right in your machine.

- It is direct drive. It has zero backlash.

- It can be BLDC or PMSM.

- It can be slotless or distributed winding.

- It can have a hollow shaft. You can pass wires through.

- It can have high pole count for smooth feel.

- It brings high torque density in a compact motor design.

- It cuts weight and size. It saves space.

What is an encoder?

- It is a tiny eye. It tells position and speed.

- It can be absolute. You know spot right on power up.

- It can be incremental. You count steps.

- It can be optical, magnetic, or inductive.

- It can use Hall effect sensors.

- It can send digital or analog output.

- It can talk BiSS, SSI, Sin/Cos, or quadrature A/B/Z.

- It drives closed loop control with PID or FOC.

Why put them together?

- You get precision positioning and repeatability.

- You get high dynamic response with quick start and stop.

- You get low cogging torque. Motion feels silky.

- You cut mechanical complexity. No belts. No gear lash.

- You improve thermal management. Heat flows to your frame.

- You raise reliability and MTBF.

- You hit tight spaces with space-saving motor kits.

I build this into smart actuator components. I pair servo motor frameless kits with encoder feedback systems. I size them with performance curves, torque speed characteristics, continuous torque, peak torque, torque constant (Kt), back EMF constant, winding resistance, winding inductance, rotor inertia, thermal resistance, and operating temperature range. I design for EMI shielding, insulation class, environmental protection, and the right IP rating.

The promise to you

- I attract your eye. Small motor. Big push. Clean look.

- I point out the need. You want accuracy. You want safety. You want speed.

- I meet the need. I build to your spec. I test. I prove.

- I position my product as your fix. I make it fit. I make it work. I back it up.

Benefits at a glance

| Feature | What it means | Your win |

|---|---|---|

| High torque density | More torque in less space | Smaller machine with more power |

| Direct drive | No gear lash | Zero backlash and smooth motion |

| Integrated encoder | Real time position and speed | Precise closed loop control |

| Hollow shaft | Cable or tube pass through | Clean build and easy service |

| Thermal path | Heat to frame | Longer life and stable output |

| Custom windings | Winding to match drive | High efficiency and cool run |

| Protocols | CANopen, EtherCAT, PROFINET | Fast setup in your PLC line |

| Harsh duty | Cleanroom, vacuum, IP, radiation tolerant, submersible | Run in tough sites with ease |

How the encoder helps

- Absolute encoder: safe start, no homing, fast boot.

- Incremental encoder: low cost, simple build.

- Watch key specs:

- Resolution in bits or CPR

- Accuracy and repeatability

- Output interface and noise care

I match encoders from Renishaw, Heidenhain, Sick AG, Dynapar, Lika Electronic, Leine & Linde, Baumer, and BEI Sensors. I also support resolver feedback for heat and shock.

Where you can use it

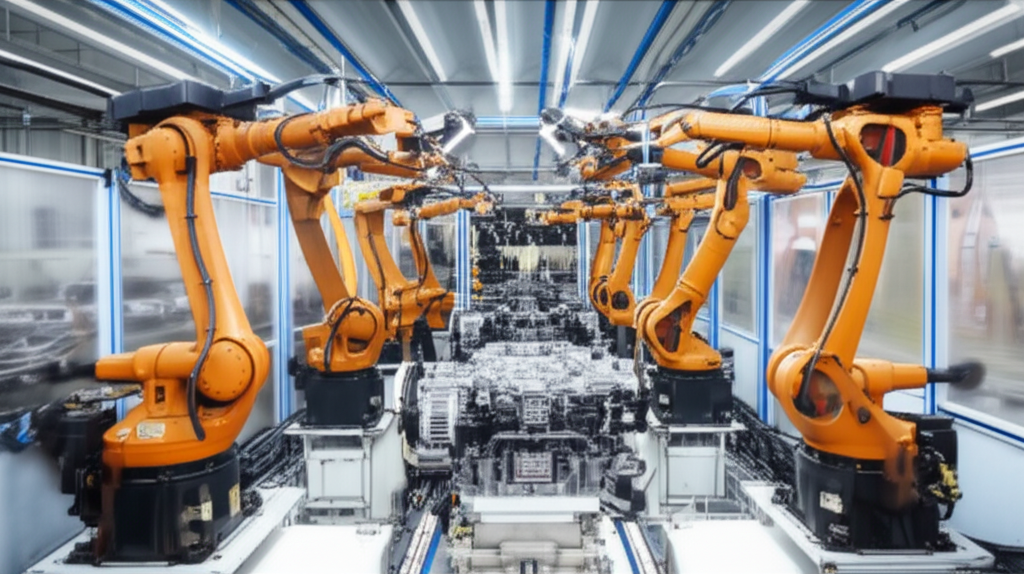

- Robotics: collaborative robots, industrial robotic arms, end effectors, direct drive robotics, Harmonic Drive joints

- Mobile robots: AGV motor solutions and AMRs

- Medical: surgical robotics, tools, drills, prosthetics, exoskeletons, and diagnostic imaging like CT and MRI

- Aerospace & defense: gimbal systems, surveillance, aircraft control surfaces, guidance systems, UAVs, drone gimbal

- Industrial automation: semiconductor manufacturing, wafer handling, vision systems, pick and place systems, packaging machinery, ATE

- Other sites: cleanroom compatible motor, vacuum compatible motor, radiation tolerant motor, submersible motor, harsh environments

Pick the right kit: simple guide

| You ask | I check | What I pick |

|---|---|---|

| How much torque | Continuous and peak torque | Right stack and torque constant |

| What speed | RPM range and torque speed curves | Poles and slot style for speed |

| How tight | Accuracy, repeatability, encoder resolution | Absolute or incremental, optical or magnetic |

| What space | OD, ID, length, hollow shaft | Reduced size motor, weight-saving motor |

| What site | Temp, vibration, dust, IP rating | Environmental protection and sealing |

| What drive | Motor drive compatibility, bus volts, amps | Match to drive/controller, PID, FOC |

| What life | Motor life expectancy, MTBF | Cool run and right thermal management |

| What cost | Cost-benefit analysis | Customization vs standard fit |

I plan prototype motor development, small batch production, and volume production. I set connector options, cable lengths, and mounting options. I document technical specifications and application notes.

My ecosystem: I fit what you use

I support drives and lines from Kollmorgen, Maxon, Faulhaber, Portescap by Sensata Technologies, Tecnotion, Moog Inc., Parker Hannifin and Parker Electromechanical, Celera Motion (Novanta), and Allied Motion. I sync with Copley Controls and Elmo Motion Control. I interface to Yaskawa, Mitsubishi Electric, Siemens, Fanuc, KUKA, Universal Robots, and Stäubli systems. I follow NEMA and IEC rules. I meet EMI/EMC needs.

A quick look: performance chart

Torque Density ██████████ 10/10

Positional Hold ██████████ 10/10

Smooth Motion █████████ 9/10

Thermal Control █████████ 9/10

Footprint Size ██████████ 10/10 (smaller bar is better, lower is great)

Note: Your exact score can change by model and load and site.

Why Jimi for your build

- I bring experience in motion control systems for machine builders and OEM teams.

- I deliver design considerations that cut risk.

- I solve system integration challenges fast.

- I give full engineering support from idea to field.

- I help you win a competitive advantage with faster time to market.

Want a ready path for linear motion today? See my lines:

- Explore high-accuracy electric linear actuators with servo precision: Electric Linear Actuators

- Add smart feedback to your system with tight control: Actuators with Position Feedback

- Build compact power stages for OEM motion: Servo Motor Actuators

- Scale robust motion in plants and labs: Industrial Automation Actuators

A peek inside the tech

I can pair a brushless DC frameless motor or a permanent magnet synchronous motor frameless with your load. I tune PID controller gains and set field‑oriented control. I shape the inertia match. I map performance curves. I verify repeatability. I check noise reduction and vibration reduction. I plan thermal resistance paths. I guard with EMI shielding.

I test in cleanroom, vacuum, IP67, IP65, heat, and shock. I set operating temperature range. I note mean time between failures (MTBF). I align to motor insulation class.

I choose the right encoder resolution for your job. A robot joint needs high bits. A conveyor needs fewer counts. A gimbal motor needs Sin/Cos for smooth blend. A lab tool may need BiSS for noise immunity.

I match the stack to your controller on EtherCAT, CANopen, or PROFINET. I route cables through a hollow shaft. I mount to your frame with simple bolts. I set cable lengths and connector options that fit your panel.

Real world use cases

- A collaborative robot joint with a direct drive motor and absolute encoder. The arm starts safe with no home move and no pinch risk.

- A surgical robot hand tool with a slotless frameless motor. It runs smooth and quiet. It fits in a tight shell.

- An AGV hub with a servo motor frameless kit and magnetic encoder. It gives high dynamic response and holds torque on ramps.

- A semiconductor wafer stage with optical encoder integration and vacuum compatible motor. It hits precision positioning with high repeatability.

- A drone gimbal with low cogging torque motor and incremental encoder. It makes video steady.

My promise

You need speed. You need space. You need control. I deliver. I build custom frameless motor kits. I design for OEM motor integration. I bring design flexibility. I keep cost vs performance in line. I ship on time.

I can guide you with a motor sizing guide and motor selection criteria. I share application notes and technical specifications. I support prototype, small batch, and volume production.

When you want lift and tilt too, I bring full lines in lifting columns, TV lifts, and desk standing gear. I can tie a frameless motor with encoder to your actuator assemblies so your build stays clean and fast.

Summary

- Frameless plus encoder gives precision, power, and seamless integration.

- You get compact design, zero backlash, and high efficiency.

- You gain closed loop control and smarter motion.

- I help you pick and build. I stand by you.

References

- Kollmorgen. Direct Drive Frameless Motors Selection Guide.

- Renishaw. Encoder Fundamentals and Applications Notes.

- Heidenhain. Absolute vs Incremental Encoders Technical Overview.

- IEC 60034 Series. Rotating Electrical Machines Standards.

- NEMA MG 1. Motors and Generators Guidance.

- Celera Motion (Novanta). Inductive and Optical Encoder Technologies.

- Copley Controls. FOC and Servo Tuning Application Notes.

- Allied Motion. Frameless BLDC Motor Integration Guide.