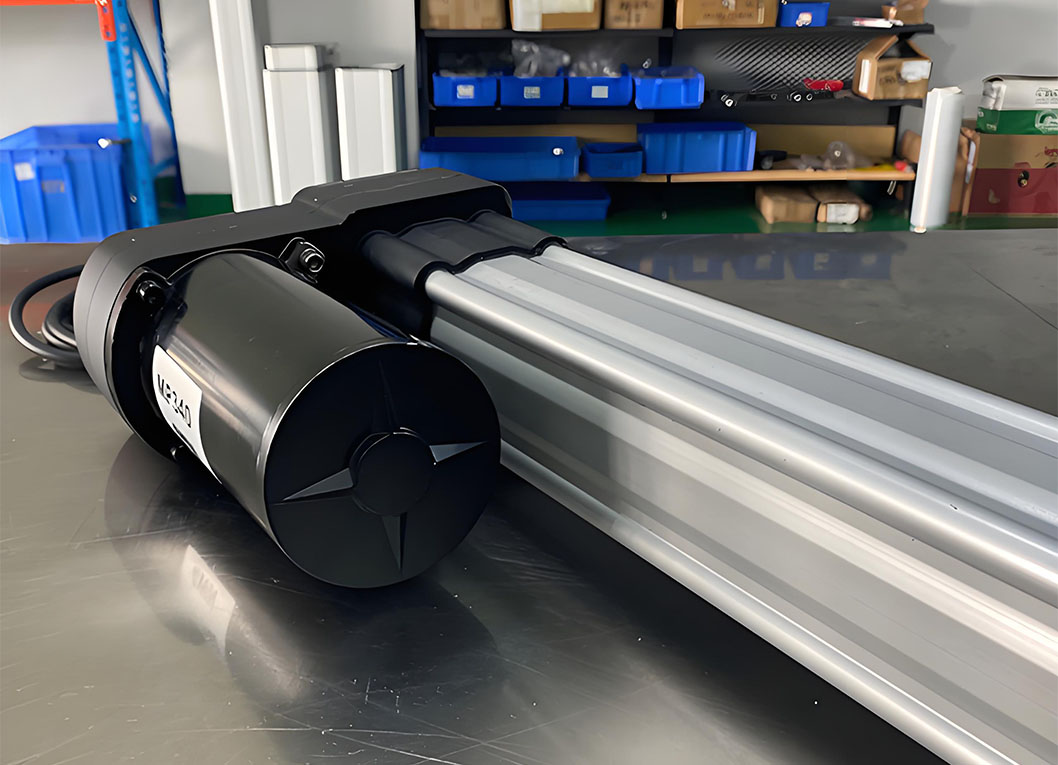

Vous le voyez tourner. Vous le voyez s'arrêter. Vous le voyez partir.

Il s'agit d'une actionneur rotatif au travail. Je fais en sorte que ce soit clair pour vous. Je fais en sorte que ce soit simple.

I. Le pouvoir de la rotation contrôlée

Vous voulez que les choses tournent au bon moment. Vous voulez des mouvements sûrs. Vous voulez de la vitesse. Vous voulez précision.

Un actionneur rotatif vous offre mouvement rotatif que vous pouvez faire confiance. Il tourne avec couple. Il tourne à un moment donné vitesse de rotation. Il contient un ensemble déplacement angulaire.

Je travaille avec le mouvement toute la journée. Je vous aide à choisir le bon outil. Je vous aide à gagner sur systèmes d'automatisation et contrôle des processus.

II. Qu'est-ce qu'un actionneur rotatif ?

Un actionneur rotatif transforme l'énergie en un mouvement de rotation au niveau de l'arbre. arbre de sortie. Il peut utiliser de l'air. Il peut utiliser de l'huile. Il peut utiliser moteurs électriques.

- UN actionneur pneumatique rotatif utilise pression pneumatique.

- UN actionneur hydraulique rotatif utilise pression hydraulique.

- Un actionneur rotatif électrique utilise tension électrique.

Certains donnent rotation limitée comme un actionneur quart de tour ou un actionneur multitour. Certains donnent rotation continue.

Vous choisissez par besoin sortie de couple, angle de rotation, la vitesse, et source d'énergie.

III. Comment cela fonctionne-t-il ?

Le principe de fonctionnement de l'actionneur est simple. L'énergie fait bouger des pièces à l'intérieur. Des pièces comme pistons, ailettes, râteliers, pignons, engrenages, et boîtes de vitesses. Cette poussée fait basculer le arbre de sortie. Ce virage fait avancer votre machine.

- Pneumatique : l'air agit sur un mécanisme du piston et du cylindre ou un type d'aube corps.

- Hydraulique : le fluide agit de la même manière, mais il donne plus. transmission de puissance et élevé couple.

- Électrique : un moteur entraîne un actionneur à engrenage ou un mécanisme de liaison actionneur. Il peut s'agir d'un courant alternatif ou continu. Il peut s'agir d'un servomoteur rotatif ou un actionneur rotatif pas à pas.

Vous pouvez ajouter retour d'information sur la position avec capteurs de position et interrupteurs de fin de course. Vous pouvez ajouter signaux de commande d'un PLC (Programmable Logic Controller) ou IHM (interface homme-machine) ou SCADA (contrôle de surveillance et acquisition de données). Vous pouvez utiliser électrovannes pour changer d'air. Vous pouvez utiliser systèmes de contrôle pour guider vitesse angulaire et s'arrêter là où vous le souhaitez.

IV. Principaux types

- Actionneurs pneumatiques rotatifs

- Actionneur à crémaillère: a piston déplace un support. Le support transforme un pignon.

- Actionneur à palettes: l'air pousse ailettes pour déplacement angulaire.

- Il s'adapte automatisation des vannes et des charges plus légères. Il est rentable.

- Actionneurs hydrauliques rotatifs

- Crémaillère et pignon, girouette, ou actionneur à arcade scotch.

- Il donne des résultats élevés couple et robuste action. Il s'adapte charges lourdes.

- Actionneurs électriques rotatifs

- Moteur entraîné par CA, DC, servomoteurs, ou moteurs pas à pas.

- Il donne positionnement précis et un contrôle intelligent. Il est efficacité énergétique dans de nombreux emplois.

- Modèles de service

- Actionneur double effet

- Actionneur à ressort de rappel

- Actionneur quart de tour et actionneur multitour

V. Pièces maîtresses

- Port d'entrée ou connexion électrique

- Cylindre ou le logement

- Piston, girouette, ou moteur

- Crémaillère et pignon ou mécanisme d'engrenage

- Arbre de sortie

- Joints et roulements

- Indicateurs de position et intégration des capteurs

VI. Comment sont-ils utilisés ?

Vous voyez des actionneurs rotatifs dans de nombreux endroits. Je vous présente des cas d'utilisation clairs.

- Automatisation des vannes

- Vannes quart de tour comme robinets à boisseau sphérique, vannes papillon, et vannes à clapet.

- Il contrôle le flux dans automatisation des usines de traitement.

- Vous les trouvez dans actionneurs pour le pétrole et le gaz, actionneurs pour le traitement chimique, actionneurs pour le traitement des eaux usées, actionneurs pour l'industrie alimentaire et des boissons, et actionneurs pour la fabrication de produits pharmaceutiques.

- Vous voyez également actionneur de vanne quart de tour, actionneur de vanne à boisseau sphérique, actionneur de vanne papillon, et actionneur de vanne à clapet ensembles.

- Machines industrielles et fabrication

- Applications robotiques et robotique industrielle utiliser rotation de la pince robotique, tableaux d'indexation, et poignet se déplace.

- Équipement de manutention utilise mécanismes de serrage, mécanismes de basculement, et appareils rotatifs.

- Machines d'emballage et machines d'emballage l'utiliser pour les bouchons et les étiquettes.

- Automatisation des lignes d'assemblage et chaînes de montage et bandes transporteuses ont besoin d'un tour et d'un lieu.

- Mouvements de machines industrielles aime les tournures simples et fortes.

- Énergie et services publics

- Actionneurs pour la production d'énergie pour turbine et contrôle du clapet.

- Actionneurs de systèmes CVC pour amortisseurs et actionneurs de clapet de four.

- Actionneurs de porte de four ouvrir et fermer les portes chaudes.

- Grands champs

- Actionnement aérospatial et défense pour les volets et le train.

- Actionnement de dispositifs médicaux dans les laboratoires et les lits.

- Applications marines et équipement des plates-formes offshore pour les mers agitées.

- Actionneurs pour équipements miniers, actionneurs pour l'industrie automobile, actionneurs pour machines agricoles, actionneurs pour machines textiles, actionneurs pour les presses d'imprimerie, et actionneurs pour la fabrication de semi-conducteurs ont besoin de virages serrés.

VII. Pourquoi choisir un actionneur rotatif ?

Tu veux l'automatisation et l'efficacité. Vous voulez moins de travail manuel. Vous voulez actionneurs à réponse rapide.

Tu veux précision et contrôle pour un positionnement précis.

Tu veux caractéristiques de sécurité actionneurs pour assurer la sécurité des personnes.

Tu veux polyvalence pour de nombreux emplois.

Tu veux des actionneurs durables et des solutions d'actionnement fiables pour les sites difficiles.

Tu veux efficacité énergétique des actionneurs et un actionneur de conception compacte où l'espace est restreint.

VIII. Ce qu'il faut vérifier avant de choisir

- Conditions d'application: couple, vitesse, angle, précision

- Disponibilité de la source d'énergie: l'air, le fluide ou l'électricité

- Conditions environnementales: chaleur, poussière, pulvérisation, corrosifs, actionneurs antidéflagrants

- Exigences de contrôle: on off, proportionnel, retour d'information

- Mesures des performances de l'actionneur et coût des actionneurs rotatifs

- Installation des actionneurs, entretien des actionneurs, et dépannage des actionneurs

- Actionneurs à indice de protection IP comme IP65 ou IP67 pour l'eau et la poussière

- Directive ATEX zones et API 6D et ISO 5211 brides pour vannes

Utiliser un calculateur de dimensionnement des actionneurs rotatifs pour obtenir le bon sortie de couple. Utiliser des outils intelligents considérations relatives à la conception de l'actionneur pour éviter les risques.

IX. Rotatif ou linéaire : Choisir le meilleur mouvement

Certains emplois nécessitent mouvement de rotation. Utiliser un actionneur rotatif.

Certains travaux nécessitent une poussée ou une traction. Utilisez un actionneur linéaire.

Je dirige avec une aide claire. Mon équipe à Jimi (Jimi Technology Co., Ltd.) fait actionneurs linéaires de haute qualité, Ascenseurs TV, et systèmes d'automatisation. Nos produits se transforment énergie électrique en mouvement linéaire. Vous élevez. Vous abaissez. Vous poussez. Vous tirez. Vous inclinez. Vous le faites d'un simple toucher. Je ne suis pas seulement un vendeur. Je suis un expert, a fournisseur de solutionset un autorité de confiance dans ce domaine.

Si votre travail nécessite une unité linéaire, je vous guide rapidement vers la bonne unité. Voir notre gamme complète de actionneurs linéaires électriques pour une énergie propre et intelligente : actionneurs linéaires électriques à haute performance.

Si votre emploi nécessite positionnement précis avec des boucles intelligentes, je vous aide à actionneurs de servomoteur et un mouvement serré : servomoteurs linéaires pour un positionnement précis.

Si vous construisez des usines ou des machines, je vous soutiens avec des piles complètes pour actionneurs d'automatisation industrielle: automatisation industrielle solutions d'actionneurs.

Si vous souhaitez un retour d'information solide, je peux vous fournir des spécifications. actionneurs avec retour de position pour faciliter IHM et PLC des liens : actionneurs linéaires avec retour de position pour le contrôle en boucle fermée.

Je vous aide également à combiner le linéaire et le rotatif en une seule fois. mécatronique plan. Je fixe systèmes de contrôle qui relient les PLC, le IHM, le SCADA, et votre domaine actionneurs de vannes. J'ajoute capteurs de position et interrupteurs de fin de course. I set électrovannes pour l'air. Je m'adapte boîtes de vitesses sur les entraînements. Je fais bouger votre ligne comme une horloge.

X. Tableau de comparaison rapide

| Type | Puissance | Couple typique | Angle | Idéal pour | Remarques |

|---|---|---|---|---|---|

| Crémaillère pneumatique | Air | Moyen | 90° à 180 | Automatisation des vannes | Simple et rapide |

| Palette pneumatique | Air | Faible à moyen | 0° à 270° | Outils légers | Compact |

| Crémaillère hydraulique | Huile | Haut | 90° à multi-tour | Machines lourdes | Force élevée |

| Etrier hydraulique de type scotch | Huile | Très élevé | 90° | Grandes vannes | Forte échappée |

| Servo électrique | Électrique | De faible à élevé | Tous | Robotique et positionnement précis | Programmable |

| Pas à pas électrique | Électrique | Faible à moyen | Marches indexées | Tables d'indexation | Faible coût |

Je peux accorder vitesse angulaire et vitesse de rotation par taille de soupape ou par jeu d'entraînement. Je peux dimensionner actionneurs double effet ou actionneurs à ressort de rappel pour la sécurité intégrée.

XI. Représentation graphique simple de la gamme de couples

- Pas à pas électrique : ""

- Servo électrique : ███████

- Crémaillère pneumatique : █████

- Crémaillère hydraulique : ██████████

- Etrier hydraulique de type scotch : ████████████

Plus de bars, c'est plus sortie de couple.

XII. Marques, normes et confiance

Je connais le domaine. Je lis les spécifications. Je teste le matériel. Je travaille avec des données provenant de leaders tels que Festo, Parker Hannifin, SMC Corporation, Rotork, Norgren, Siemens, Bosch Rexroth, Bimba Manufacturing, Flowserve, AUMA, et Emerson. Je m'aligne sur ISO 5211 règles de montage. Je suis les Directive ATEX dans les zones à risque. Je taille à API 6D pour vannes quart de tour.

Je vérifie Actionneurs à indice de protection IP pour les lavages. J'apparie amortisseurs dans CVC. Je m'adapte systèmes de transport et la manutention des matériaux cadres. Je construis systèmes d'automatisation qui se déroulent proprement dans chaînes de montage et machines d'emballage.

XIII. Coût, entretien et disponibilité

Je garde coût des actionneurs rotatifs en fonction des besoins. Je planifie le nettoyage installation des actionneurs. J'ai mis en place des entretien des actionneurs. J'écris dépannage des actionneurs que votre équipe peut utiliser.

I log mesures de performance de l'actionneur afin que vous puissiez vous améliorer. Je surveille de près l'usure des scellés et roulements. Je vérifie pistons, cylindres, ailettes, pignons, et entraînement par engrenage s'adapter.

XIV. Votre besoin et ma promesse

- Attirer l'attention

Vous voulez un virage en douceur. Vous le voulez tout de suite.

- Souligner le besoin

Votre ligne doit respecter les délais. Votre usine doit rester sûre. Vos vannes doivent se fermer à temps.

- Répondre aux besoins

Je taille le bon pneumatique, hydraulique, ou électrique unité rotative. J'ajoute des retour d'information sur la position. Je le renvoie à votre PLC, IHM, et SCADA.

- Positionner le produit

Lorsque vous avez besoin de pousser et de tirer, je fais appel à notre Jimi actionneurs linéaires. Ils s'associent bien à vos ensembles rotatifs. Ils soulèvent. Ils abaissent. Ils poussent. Ils tirent. Ils inclinent. Ils le font en appuyant sur un bouton.

Voir mon expérience actionneurs linéaires électriques maintenant. Voir mon actionneurs de servomoteur pour un contrôle optimal. Voir mon actionneurs d'automatisation industrielle pour alimenter votre ligne. Voir mon actionneurs avec retour de position pour les boucles serrées. Je vous aide à passer du plan à la course.

XV. Tendances futures

Je vois actionneurs intelligents et IdO liens. Je vois miniaturisation. Je vois plus l'efficacité énergétique. Je vois des liens plus étroits avec les mécatronique et systèmes de contrôle.

Je vous apporte la meilleure solution aujourd'hui. Je vous prépare à l'avenir.

Références

- Rotork. Valve Actuation Basics. Consulté en 2025.

- Emerson. Actuator Selection Guide. Consulté en 2025.

- ISO 5211. Robinetterie industrielle - Accessoires pour actionneurs à fraction de tour. Édition actuelle.

- API 6D. Spécification pour les vannes de tuyauterie et de tuyauterie. Édition actuelle.

- Directive ATEX 2014/34/EU. Matériel pour atmosphères explosives.

- Festo, Parker Hannifin, SMC Corporation, Bosch Rexroth, Flowserve, AUMA. Fiches techniques sur les actionneurs pneumatiques, hydrauliques et électriques.

- Notes d'application sur les commandes et les pneumatiques de Siemens et Norgren. Consulté en 2025.

Résumé

Vous savez maintenant ce qu'est un actionneur rotatif. Vous savez comment il fonctionne. Vous savez types d'actionneurs rotatifs. Vous connaissez la clé applications des actionneurs rotatifs.

Vous pouvez choisir en toute confiance. Vous pouvez planifier avec soin. Vous pouvez agir maintenant.

Je suis là pour vous aider. J'apporte expérience, expertise, autorité, et fiabilité. Je suis à vos côtés, de l'idée au démarrage. Je vous aide à avancer.