What Are Food-Grade Stainless Steel Electric Cylinders and Why Are They Crucial for F&B?

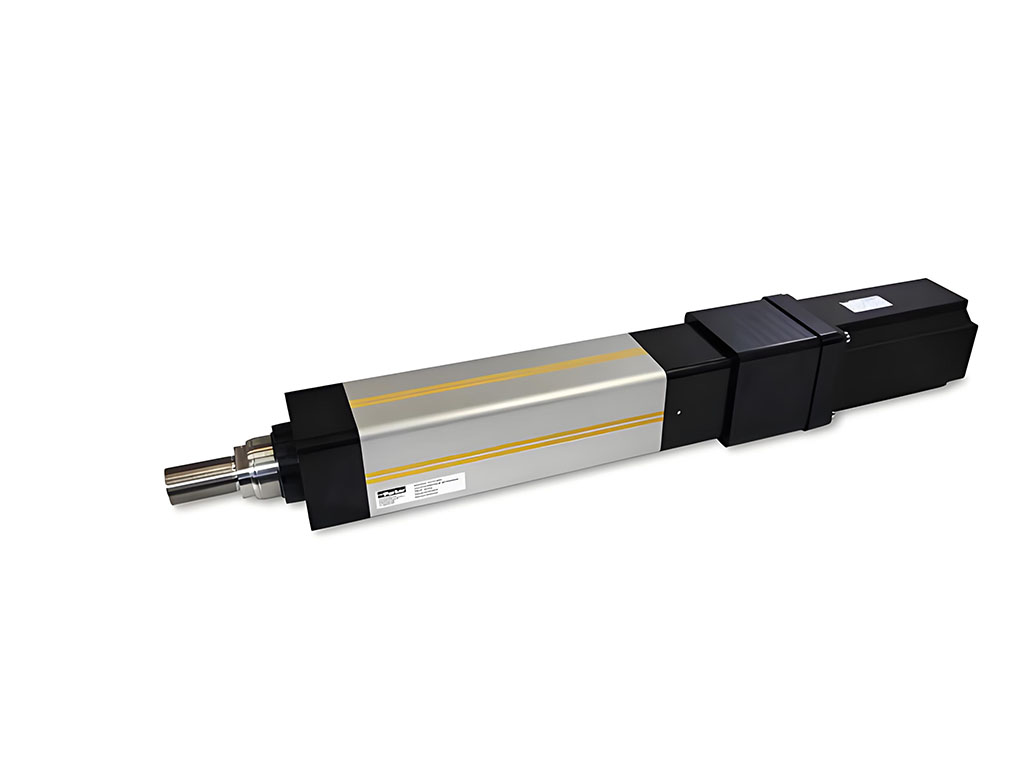

Photo a food factory where devices move with excellent precision, and every little thing looks clean and glossy. There’s a reason for that shine: food-grade stainless steel electric cylinders. These small but mighty devices power the lifts, pushes, and even the tilts you need in processing—just at the press of a button.

So, what is an electrical cylinder? It’s a basic gadget that utilizes an electrical motor to transform spinning activity right into straight-line (direct) activity. It’s like a magic arm that goes up, down, or laterally when you tell it to. The “food-grade stainless-steel” part suggests this arm can be utilized around food. It’s smooth, shiny, and does not rust. Frequently, you’ll see kinds like 304 or specifically 316L stainless steel. These qualities resist rust, clean up quickly, and will not trap germs or dust. In the food company, safety is crucial. Food-grade cylinders get designed with no sharp corners, minimal gaps, rounded edges, and tight seals. Bacteria or leftover bits? They don’t stand a chance here.

Why does this matter? You don’t want germs growing or food getting stuck where you can’t clean. These cylinders help prevent that—guaranteed.

Electric vs. Traditional Actuators: A Game-Changer for F&B Operations

Let’s look at how these compare to the old ways, like pneumatic cylinders or hydraulic cylinders. Maybe you’ve used them before—air or oil pushes a rod forward and back.

Unmatched Precision and Control for Critical Processes

Electric cylinders win big on precision. You can set them to stop at any type of area you desire, each and every single time. Need to fill up a container to precisely 300ml or slice cheese to a specific 10mm? No problem. This precise control means less waste and the same portion every run. According to major manufacturers, you get repeatability down to 0.02 mm—that’s like splitting a hair!

Significant Energy Savings and Reduced Operating Costs

Here’s a huge plus: you only use power when the cylinders move. No need to keep noisy air compressors running all the time. That means you save energy—and money. One technical paper shows switching from pneumatics to electric can cut power use by up to 90%. Over a year, that’s cash in the bank.

Enhanced Cleanliness and Reduced Contamination Risk

No oil leaks. No blown seals spraying air. Just smooth, sealed movement. This makes electric cylinders the safe choice for washdown environments. They help you fulfill rigorous food requirements, like FDA or EHEDG guidelines, where also a little leak might take the chance of a recall.

Lower Maintenance Demands and Longer Lifespan

Less moving parts mean fewer things break. If you’re tired of constant fixes or unscheduled downtime, electric cylinders show up strong here too. Some factories report up to 30% less surprise breakdowns after switching.

Key Features and Design Considerations for F&B Compliance

Let’s break down the essential features you’ll want.

The Importance of IP Ratings, Especially IP69K

Look for IP ratings—a number system that shows how well stuff handles water and dust. For food factories, the IP69K rating stands at the top. It means a cylinder can take high-pressure, high-temp water jets from all directions. That’s the toughest cleaning test gear can face.

Selecting the Right Stainless Steel Grade (304 vs. 316L).

Both 304 and 316L stainless steel sparkle, however 316L includes molybdenum– making it even harder versus severe cleaning agents and salt. Got sauces, dairy, or any kind of procedure with lots of salt?

FDA-Approved Materials and Seal Technology

The secret to true food safety isn’t just the metal—it’s also the seals and lubricants. Only FDA-approved elements must touch your items. Advanced securing quits water, dust, and cleansing fluids from sneaking in.

Holistic Hygienic Design: Beyond Just Materials

It’s not just regarding the steel– it has to do with the entire form and construct. Smooth, sloped surfaces assist water escape. No cracks or hidden spots. Simple details, like mounting bolts outside the food zone, all add up to one thing: easier cleaning and better safety.

Practical Applications of Food-Grade Electric Cylinders Across the F&B Industry

Where can you use these cylinders? Pretty much everywhere in a food plant:

Precise Filling and Dosing Systems

Electric cyndrical tubes allow you set exact fill degrees for containers, trays, or bags– no thinking, no waste.

Automated Cutting, Slicing, and Portioning.

Every piece or section comes out the exact same dimension, each time. That keeps your customers happy and saves you money in materials.

Reliable Packaging and Sealing Operations

From sealing bags to closing trays, these cylinders get timing and pressure right.

Dynamic Sorting and Diverting Mechanisms

Need to push snack packs onto the right conveyor? These are your go-to.

General Automation in Harsh Washdown Zones

If it needs to move and gets washed often, an electric cylinder with a high IP rating is the best bet. For heavy loads, check out solutions like heavy-duty linear actuators.

Navigating Regulatory Compliance: FDA, EHEDG, and Beyond.

Recognizing FDA Guidelines for Food Contact Materials.

The FDA spells out which products can securely touch food. FDA-compliant cyndrical tubes make use of accepted steels and seals, so you stay in the clear.

Adhering to EHEDG Principles for Hygienic Design.

The EHEDG establishes regulations for easy-to-clean devices. Adhering to these guidelines isn’t simply wise– it’s a have to for exporting to Europe or operating top-tier plants.

Other Relevant Certifications (e.g., NSF, ISO).

Some purchasers or markets need added stamps, like NSF or ISO marks. These reveal your arrangement’s genuinely first-rate.

Avoiding problem keeps your items secure and your track record strong. Ignore criteria, and you run the risk of recalls, fines, and mad headlines.

Picking the Optimal Food-Grade Electric Cylinder for Your Needs.

To select the right cyndrical tube:

- Know your called for pressure, rate, and just how usually it runs.

- Examine your plant’s temperature level, wetness, and chemicals.

- Ensure it’s suitable with your control systems.

- Believe beyond sticker price. Consider upkeep, downtime, and components expenses.

- Partner with trusted experts, not bargain-basement traders. China Electric Cylinder Factroy offers deep support and proven reliability.

A strong supplier will help you select, customize, and integrate the perfect fit.

FAQ (Frequently Asked Questions).

What is the distinction between pneumatically-driven and electric cylinders in food processing?

Pneumatically-driven cyndrical tubes make use of air. Electric cylinders use electric motors. Electric kinds bring more control, reduced power usage, and much less upkeep.

What stainless steel is food grade?

304 and 316L are both considered food grade. 316L has better corrosion resistance, especially with salt or harsh cleaners.

Are electric actuators food safe?

If labeled “food-grade” with appropriate materials, seals, and accreditations, of course– they’re risk-free for food call.

What IP ranking is needed for food handling devices?

IP69K is the gold criterion. It stands up to high-pressure, high-temp cleaning.

What are the advantages of electrical cyndrical tubes for sanitary applications?

They don’t leak, are easy to clean, save energy, and cut downtime.

Just how do electric cylinders guarantee tidiness in washdown atmospheres?

Hermetic sealing, smooth surfaces, and corrosion-proof products maintain them bacteria-free.

What is EHEDG accreditation and why is it important for F&B?

EHEDG checks gear for easy cleaning and germ resistance. It’s key for food safety and global trade.

How can electric cylinders reduce energy costs in food plants?

They use power only when moving. No need to run compressors all day.

What are common applications of electric cylinders in packaging lines?

Filling, sealing, pushing, sorting, and lifting—anything that moves or measures.

Where can I buy food-grade stainless steel electric cylinders?

Turn to China Linear Actuator Manufacturer or Stainless Steel Actuators for trusted products and remedies.

Conclusion & Next Steps

Food-grade stainless steel electrical cylinders are transforming the face of contemporary food automation. They keep your line clean, safe, and running at peak precision. They use less power, break down less, and clean up fast. That saves you money, keeps your products safe, and makes audits a breeze.

At Jimi Technology, we’ve spent years perfecting automation for food and drink factories. From smart design to rugged materials, our cylinders meet all the toughest standards. We’re not just a maker—we help you turn your ideas into a reality.

Ready to modernize your plant? Explore electric linear actuators and food-grade electric cylinders or contact Jimi for expert service. Future food factories run on safe, smart, energy-saving automation. Yours should too.