Understanding Industrial Cylinders: The Foundation of Motion Control

Visualize a maker on a hectic that gets hefty boxes, lines them in excellent heaps, and never ever misses out on a beat. How does it move things so smoothly? The unsung hero is often a linear actuator—the powerhouse behind opening, pushing, lifting, or tilting in every corner of modern industry. Whether you are an engineer searching for peak precision or an operations chief who wants fewer breakdowns, the type of actuator you pick sets the pace. The big three? Electric, pneumatic, and hydraulic cylinders.

Each cyndrical tube uses different techniques. That implies your selection can change everything, from exactly how fast a maker relocates to just how quietly it works. Allow’s check out why it matters, and exactly how making the right choice can provide your company a genuine edge.

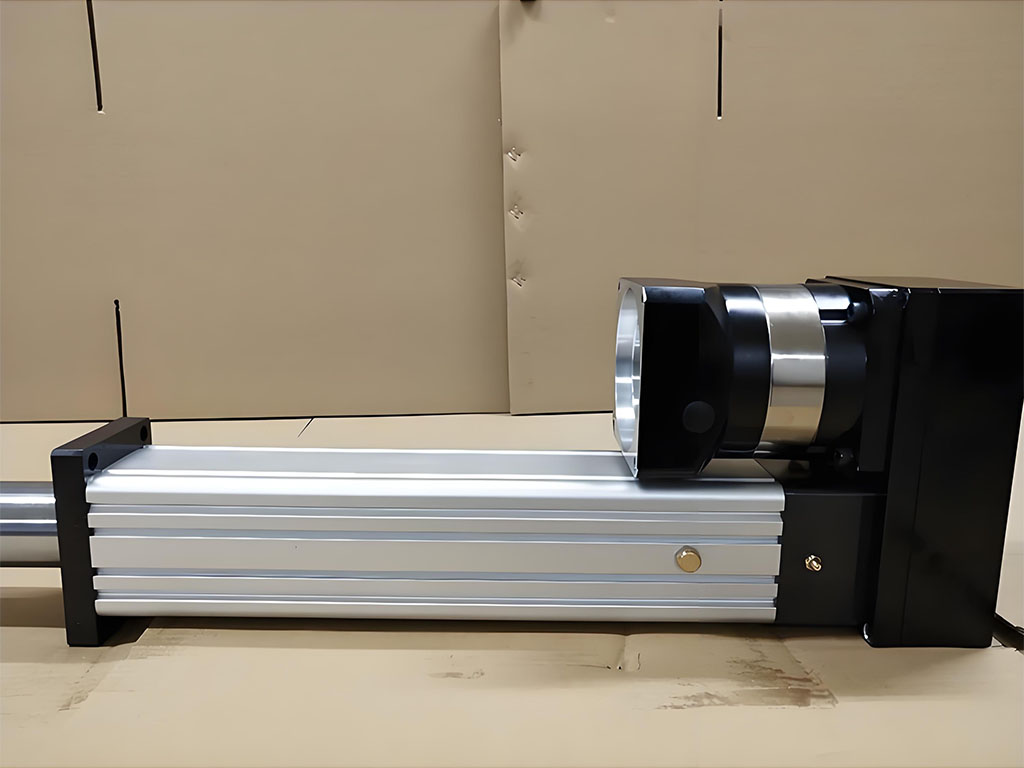

Electric Cylinders: Precision, Efficiency, and Control

Electric cylinders are like the “smart kids” of actuators. They change electrical energy into line movement. Inside, small but mighty servo motors or stepper motors turn ball screws or lead screws to push or pull with amazing accuracy.

Why do so many engineers love electric cylinders? Here’s why:

- Pinpoint Precision: You can stop or start at any spot, over and over, down to 0.005 mm.

- Energy Efficient: Power up only when moving. No extra waste.

- Clean and Quiet: No leaky oil, no loud hum. Perfect for labs or clean rooms.

- Flexible Control: You get programmable moves for any task using a Programmable Logic Controller (PLC).

- Minimal Maintenance: Fewer parts to wear out means less downtime.

Yet, there are some tradeoffs:

- Higher Upfront Cost: Cutting-edge parts and controls cost more early on.

- Force Limits: They punch hard but can’t compete with hydraulics for the very heaviest jobs.

- Heat Sensitivity: Extreme temperatures require extra sealing.

Common uses: Electric cylinders rule in packaging, lab automation, precise presses, robotics, and medical devices. They’re everywhere clean speed and precision count. Want to see what peak electric actuation looks like? Check out Electric Linear Actuators and our flagship Electric Cylinders.

Pneumatic Cylinders: Simplicity, Speed, and Cost-Effectiveness

Think of pneumatic cylinders as the “fast sprinters” of the group. They use compressed air to drive a piston, moving things in a flash. Simple inside, speedy outside.

What’s great about pneumatics?

- Low Start-Up Cost: Hardware is simple and widely available.

- Easy Install and Repair: Plug them in, and you’re off.

- Quick Moves: Ideal for rapid, back-and-forth action in picking, clamping, and sorting.

- Safe: No hazardous fluids or wires.

The snags?

- Lower Precision: Air compresses, so stops can be a little soft. That means less exact placement.

- High Energy Usage: Compressing air eats up lots of electricity, upping the bill.

- Noisy Operation: Expect some hissing.

- Limited Force: Pushing power maxes out at a few thousand pounds.

- Air Leaks Waste Money: Bad seals mean wasted air and cash.

Common uses: Pneumatic cylinders shine in assembly lines, door openers, food handling, and other jobs where quick, simple movement matters. For solutions built to last, explore Pneumatic Linear Actuators.

Hydraulic Cylinders: Raw Power, Durability, and Heavy-Duty Performance

Need to lift something as heavy as a car? Enter hydraulic cylinders—the “strongmen” of actuation. They use pressurized oil, powered by a hydraulic power unit (HPU), to move a piston with stacks of force.

Here’s what they bring:

- Maximum Power: Handle millions of pounds—no sweat.

- Size-Efficient: Small packages, big muscle.

- Toughness: Built to survive in harsh and dirty places.

- Consistent Force: Smooth, steady power with strong shock absorption.

Still, heavier power comes with challenges:

- Complex Install: HPUs, fluid lines, and piping get tricky.

- Messy and Noisy: Watch for oil leaks and hums from the pumps.

- Higher Maintenance: Seals and fluids need regular care.

- Less Efficient: Always running the pump drains energy.

- Possible Fire Hazards: Some oils can burn.

Where they rule: You’ll find hydraulic cylinders in cranes, presses, construction gear, marine lifts, and anywhere raw force is key. When you need all-out strength, check Hydraulic Linear Actuators.

Direct Comparison: Electric vs. Pneumatic vs. Hydraulic Cylinders Side-by-Side

You’re probably wondering, “Which is best for me?” Here’s a simple breakdown:

| Feature | Electric | Pneumatic | Hydraulic |

|---|---|---|---|

| Max Force | High (100,000 lbs+) | Low (few 1000 lbs) | Extreme (millions lbs) |

| Speed | Fast, controlled | Fastest (light load) | Steady (heavy load) |

| Precision | Highest (±0.005mm) | Low | Good (needs controls) |

| Energy Efficiency | 80-90% | 10-20% | 40-60% |

| Initial Cost | High | Low | Moderate-High |

| Maintenance | Low | Moderate | High |

| Noise | Quiet | Noisy | Loud |

| Cleanliness | Cleanest | Clean air only | Can be messy |

| Footprint | Small-medium | Small | Large |

| Typical Life | Longest | Moderate | Long (with care) |

Want more details? Our China Electric Cylinder Factory has in-depth comparisons and a full range of options.

Choosing the Right Cylinder for Your Application: Key Decision Factors

There’s no “one size fits all” cylinder. Here’s what to ask yourself:

- How much force and speed do I need?

Lifting a truck? Think hydraulic. Rapid, light movement? Pneumatic. Need pinpoint stops? Electric.

- What environment will it run in?

Is it wet, dusty, hot? Electric needs protection in harsh spots, hydraulics shrug off dirt.

- What’s my budget?

Upfront cost matters, but so does total cost of ownership (TCO). Electric often costs less to run and maintain over time.

- What energy sources are handy?

Plenty of air? Go pneumatic. Strong electrical? Choose electric. Already have hydraulic in place? Add a cylinder there.

- Who will maintain it?

Electric is simple—less mess, less fuss. Hydraulic needs more skilled hands.

- How important is safety and compliance?

Each type has safety needs—pressure, power, environmentally safe fluids.

Not sure? Give us your project specs and we’ll recommend the best fit—fast.

Future Trends and Innovations in Actuation Technology

Machines get smarter every day. So do actuators.

- Surge of Electric: Electric cylinders are leading the fee with Industry 4.0 and IoT.

- Crossbreed Power: New systems mix electrical and hydraulic for the very best of both globes.

- Smart Data: Sensors and analytics forecast break downs before they happen.

- Smaller sized, Stronger: Shrinking dimensions, increasing force– for exact moves in limited spaces.

We at Jimi constantly look ahead. Our engineers get on the edge of automation trends, creating quieter, lighter, and cleaner services for tomorrow’s wise factories.

Often Asked Questions (FAQ)

What is the primary difference between pneumatically-driven, hydraulic, and electric cylinders?

Pneumatic uses air, electric uses electric motors, hydraulic usages oil. Each brings its very own staminas.

Which kind of cylinder is one of the most effective?

Hydraulic cylinders win for power. They move the heaviest loads.

Are electric cylinders better than hydraulic in general?

Hydraulic cylinders win for power. They move the heaviest lots.

What are the disadvantages of pneumatic cylinders?

Lower precision, high energy cost, and less pushing power.

Which cylinder system is the most energy efficient?

Electric. It uses only the power you need.

What are the pros and cons of hydraulic cylinders?

Massive power and durability are pros. Mess, noise, and maintenance are cons.

When should you use an electric linear actuator?

Use one when you need clean, quiet, programmable, and accurate movement.

Is pneumatic or hydraulic actuation more expensive to run?

Pneumatic is typically the costliest over time due to energy use.

Can electric actuators completely replace hydraulic systems?

Not for the heaviest loads—yet. For medium jobs, they’re catching up fast.

What factors determine the choice of an industrial actuator?

Force, speed, precision, environment, cost, energy, and maintenance needs.

Jimi Technology: Your Trusted Partner in Motion Control

Why trust Jimi? Simple. **We don’t just sell actuators—**we solve problems. With years of hands-on experience, top-grade manufacturing, and strict quality control, we’ve built solutions for robotics, factories, medical systems, and more.

Need a custom solution or large-volume reliability? Let our team help. Our products—from Servo Linear Actuator Factory to Heavy-Duty Linear Actuators —are made to move your world.

Conclusion & Next Steps

There’s no single best cylinder. Each type fits its own job. Take a good look at your needs—force, speed, environment, budget, and safety. Ready to take the leap? Dive into our product pages for Industrial Linear Actuators or Actuators with Position Feedback. Reach out to Jimi Technology and let’s set your automation in motion—smarter, faster, stronger.