Imagine this: you’re loaded down with grocery bags, your hands aren’t free, and rain threatens to soak you. Yet your car’s tailgate opens, smooth and silent, with simply a wave. Or, on a hot day, you rise, touch a button, and your sunroof relapses, letting in light and wind. That simple magic comes from electrical actuators– hidden assistants that make life easier, much safer, and more comfy.

The Core of Automotive Automation: What Are Electric Actuators?

Electric actuators are special devices in your car. They transform electrical power into activity– either relocating points in a straight line (straight actuator) or transforming them (rotary actuator). In cars, these smart movers do more than spin or push. They give you precise, repeatable motion for jobs like raising a tailgate or sliding open a sunroof.

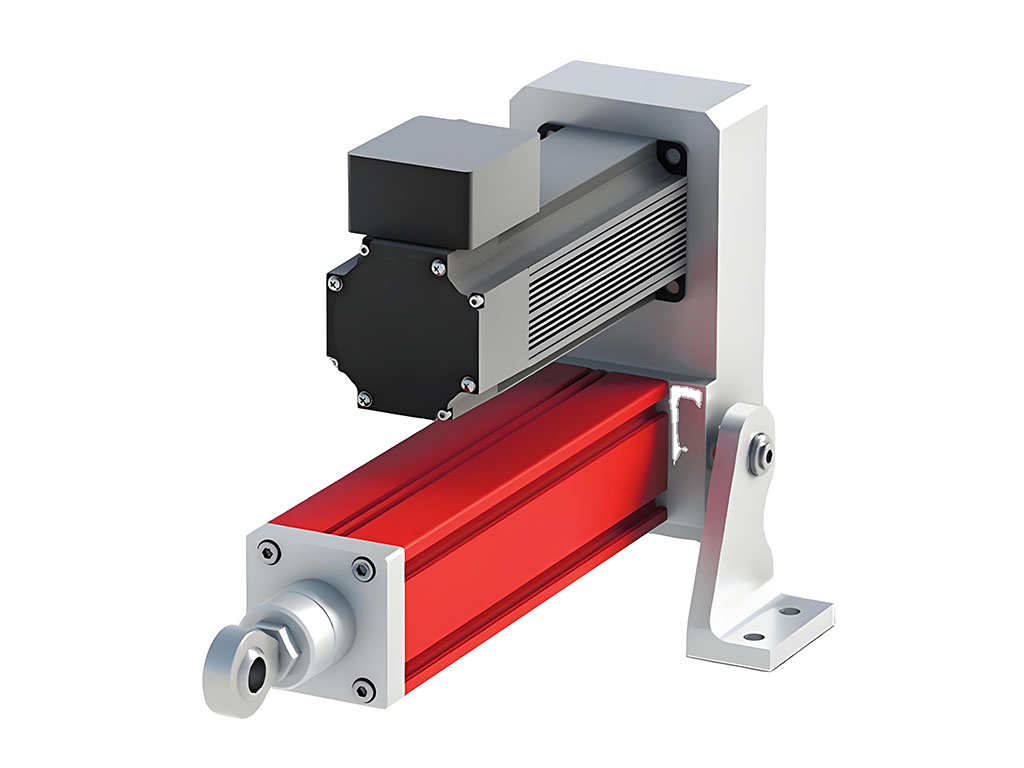

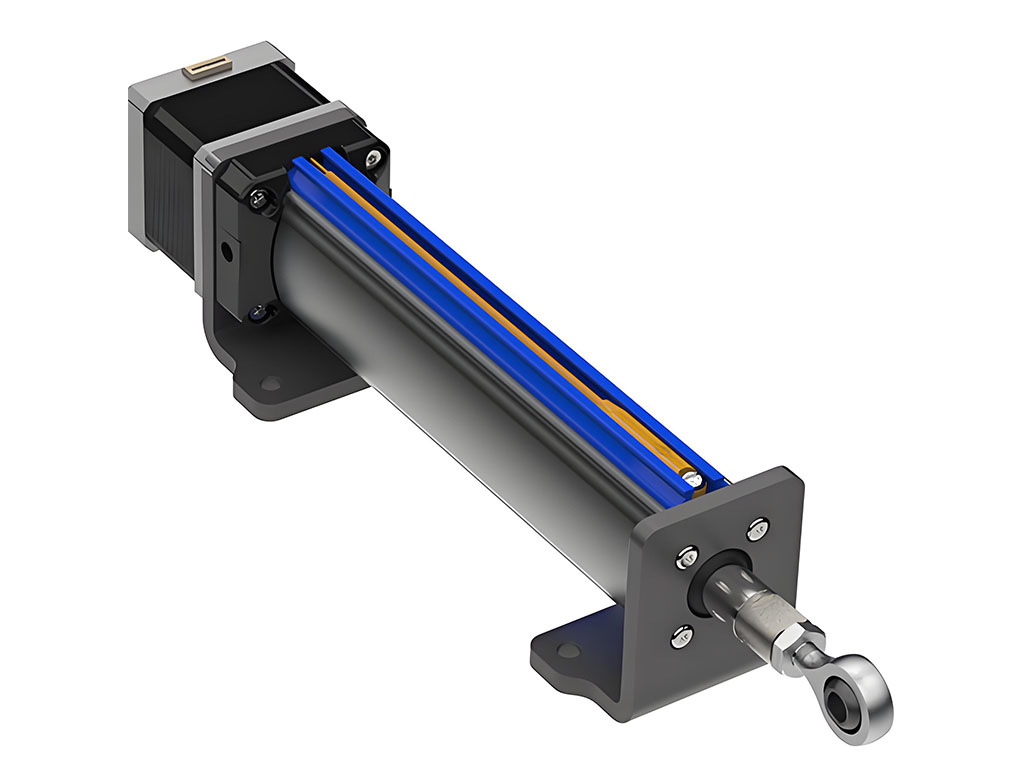

Below’s how it works. An electric actuator utilizes a small electric motor, usually with a gearbox, to develop activity. Then, smart design transforms that rotating into controlled motion, occasionally utilizing a lead screw or a shelf and pinion. All of this gets managed by basic digital controls. Unlike a plain electric motor, the actuator relocates simply the correct amount, quits where it should, and keeps things smooth and peaceful.

Why do car manufacturers select actuators over various other systems? You obtain:

- Precision: Stops exactly where required.

- Control: Quiet, mild movement– no slamming or unexpected jerks.

- Efficiency: Uses energy just when required.

- Clean operation: No oil leakages or unpleasant hydraulics.

Driving Sunroof Innovation: Electric Actuators in Action

Sunroofs include light and air, making any type of trip feel open and fresh. Today’s sunroofs can be found in many kinds– sliding, turning, breathtaking, also convertible tops– all with different actuator needs.

Let’s break it down:

- Sliding and turning sunroofs make use of tiny direct actuators that press or pull the panel along a track.

- Panoramic roofs may require several actuators for smooth, even movement.

- Some roofs need a rotary actuator if the panel must tilt.

The magic happens when you press a button. The motor whirs, a cable or track guides the panel, and position sensors track every move. Want it open halfway? No problem—the actuator stops mid-track, every time.

Safety matters, too. Most sunroof systems have robust anti-pinch features. If something blocks the panel, sensors find the obstacle and the actuator reverses instantly, keeping fingers, hands, or anything else secure. Systems like these frequently meet difficult safety laws like ECE R21 or FMVSS 118.

And what does this mean for you? You get a sunroof that’s:

- Easy to control with one touch.

- Reliable, opening smooth and quiet for years.

- Built with your safety in mind.

Seamless Access: How Electric Actuators Power Automated Tailgates

Now, think about the trunk. No lifting, no fuss—just a gentle, automatic rise and close. That’s the power of electric tailgate actuators at work.

Here’s the recipe:

- A linear actuator (often called a spindle drive) does the heavy lifting.

- Sometimes, gas struts help by supporting the weight.

- Sensors watch for obstacles or overloads.

- Electronics manage the open, close, and stopping points.

You don’t even need a free hand. With hands-free sensors, a kick under the bumper is enough to trigger the works. Many systems let you set how high the tailgate opens—no more bumping the garage roof. Advanced models even use energy efficiently, needing as little as 0.2 kWh per 100 cycles.

Safety shines right here as well. If the gate hits something on the way down, the system reverses, soft-closes, and lets you understand with a beep. These protocols secure people, animals, and your car itself.

A Real-World Example

One major automaker used compact linear actuators in its new tailgate system. The result? A stunning 15% space saving and 20% weight reduction. Less weight means better fuel efficiency, and more room means sleeker design.

Delving Deeper: Types and Technologies of Automotive Electric Actuators

Linear vs. Rotary Actuators for Vehicle Applications

- Linear actuators push, pull, lift, and lower. You’ll find them in tailgates, power seats, and windows. They shine where you need a straight-line movement.

- Rotary actuators twist or turn. They handle things like air vent controls or some tilt features.

Choosing between linear and rotary comes down to the job at hand. Need to slide a sunroof panel? Go linear. Want to spin an HVAC damper? Pick rotary.

Understanding the Driving Force: Motor and Gearbox Integration

Three motor types rule this world:

- DC Brushed Motors – Simple and affordable, often seen in basic applications. Learn more about Brushed DC Actuators

- Brushless DC (BLDC) Motors – More efficient and long-lasting. Perfect for heavy-duty needs.

- Stepper Motors – Great for step-by-step, precise movement.

But motors alone can’t do it well. That’s where gearboxes come in—think of them as muscle-multipliers. They increase torque, slow down the speed, and give pinpoint accuracy. Mix in a lead screw or rack and pinion, and you turn rotary spins into straight movements.

For those curious about advanced options, Electric Linear Actuators, Ball Screw Actuators, and even Servo Motor Actuators all play their part.

The Brains Behind the Brawn: Control Systems and Sensors

Actuators are the muscle. However what informs them what to do? Electronic Control Units (ECUs).

- ECUs take signals from buttons, sensors, or your key fob.

- They use protocols like CAN bus or LIN bus to “talk” with the car’s brain and other systems.

- Sensors keep a close eye—Hall effect sensors track position (often accurate to 0.1mm), current sensors spot overloads, and temperature sensors help with longevity.

This tight synergy allows your sunroof or tailgate action with a mind behind the brawn– safe, smooth, and wise.

Design Challenges, Reliability, and Future Outlook for Automotive Actuators

Getting Over Design Hurdles: Space, Load, and Environment

Modern vehicles pack a lot into small spaces. Actuators must fit into tight spots, lift heavy weights (like a giant glass tailgate), and handle brutal conditions—heat, cold, bumps, and moisture. Noise can’t sneak in either, since you want rides that are smooth and quiet. Design matters.

Guaranteeing Long-Term Performance: Reliability and Maintenance

Quality matters. At Jimi, we design actuators that last—over 100,000 cycles without fail, according to industry tests. That means your tailgate should open and close for years with no hiccups.

What could go wrong? Sometimes a motor may fail, a sensor may give up, or wiring might loosen. Most problems are rare, but if they do show up, replacement is straightforward. Most systems are built to be nearly maintenance-free.

If you want extreme resilience, Heavy-Duty Linear Actuators and Waterproof Linear Actuators supply additional assurance.

The Road Ahead: Emerging Trends and Innovations

Actuators maintain getting smarter and lighter. We see:

- Integration with smart vehicle features—think predicting wear or talking with navigation systems.

- Better sensors so systems adjust for safety before trouble strikes.

- Miniaturized styles for smaller, lighter vehicles.

- Environmentally friendly products and manufacturing to shield the world.

FAQ

What is an electric actuator in a cars and truck?

It’s a gadget that turns electric power into activity, letting you open or close things like sunroofs or tailgates.

Just how does an electric tailgate job?

A linear actuator presses or pulls the tailgate while sensors and a controller take care of motion and security.

What type of motor is utilized in a sunroof?

Mainly DC or brushless DC (BLDC) motors, selected for peaceful, trusted, and controlled motion.

Are electric sunroofs reliable?

Yes. Quality sunroof actuators can last for over 100,000 cycles and use sensors to avoid pinching or damage.

Can you manually open an electric tailgate if it fails?

Most systems let you override or manually open the tailgate in emergencies—always check your car’s manual.

What is the distinction between an electrical motor and an actuator?

A motor spins or relocates, yet an actuator utilizes that activity in a controlled way to do a certain work.

What are the benefits of an electric tailgate?

Hands-free operation, adjustable height, improved convenience, more safety for you and your things.

Just how much power does an electrical tailgate system take in?

Common modern-day systems utilize just 0.2 kWh per 100 open/close cycles.

That are the leading makers of vehicle actuators?

Jimi, Bosch, Continental AG, Magna International, Johnson Electric, and Nidec Corporation.

What prevail issues with electric tailgate actuators?

Rare motor failings, defective sensing units, or wiring concerns– generally easy to deal with or replace.

Conclusion & Next Steps

Electric actuators are the silent champs of modern-day vehicles. They bring you comfort, security, and ease, whether you’re opening up a sunroof to capture the wind or packing your trunk in the rain. With market development strong–$14.2 billion by 2027– it’s clear these systems are the way ahead.

At Jimi, we don’t just make actuators– we innovate, test, and supply reliability you can rely on. Our products integrate smart style, tough materials, and advanced technology, making us the companion of selection for both automakers and enthusiasts. Need more info or want to upgrade your system? Dive into our advanced Electric Linear Actuators, explore precision Ball Screw Actuators, or check out how Actuators with Position Feedback make everything smarter.

Ready to unlock more convenience? Reach out to Jimi—your trusted expert in automotive automation—and turn possibility into reality.