Do you want smooth moves?

Do you want fast lines?

Do you want less wear?

I can help. I will show you electronic camming. I will show you what it is. I will show you how it works. I will show you how it can help you today.

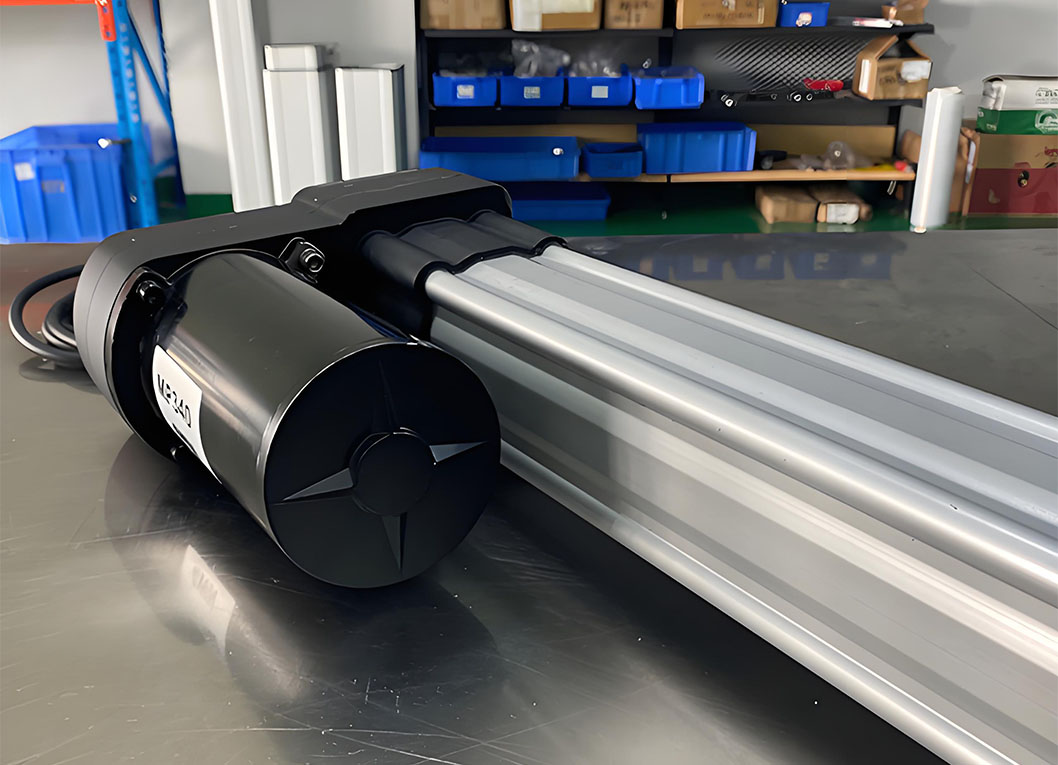

Who am I? I am from Jimi (Jimi Technology Co., Ltd.). We make linear actuators, TV lifts, and automation systems. Our gear turns electric power into linear motion. You can raise. You can lower. You can push. You can pull. You can tilt. You can do it at the touch of a button. We are not just a seller. We are an expert. We are a solution provider. We are a trusted authority.

What is electronic camming?

You know a mechanical cam. It is a hard part. It turns. It makes a set path. It can move a part up or down. It can push. It can pull. It works. It is simple. It is fixed.

An electronic cam does the same job. It does it with software. It does it with a servo drive and a servo motor. It uses a motion controller or a PLC. It reads a master axis. It moves a slave axis. It uses a cam profile and a cam table. It can change fast. It can sync smooth. It can make a clean trajectory.

Why demystify? This tech looks hard. It is not. I will make it easy.

How does it work?

Think of a band. The master axis is the beat. The slave axis plays to the beat. A encoder is the ear. The feedback device tells us the beat. The motion controller runs the show.

- The master axis can be a rotary encoder. It can be a virtual master.

- The slave axis is your servo motor. It follows the cam profile.

- The cam profile sets position, velocity, acceleration, and jerk.

- The gearing ratio sets the link. You set the sync.

- The cam table holds the curve. You load it. You edit it. You store it.

You can use many profile types. You can use Cycloidal. You can use Modified Sinusoidal. You can use Polynomial. You can use S-curve. You can use Trapezoidal. You can use Velocity profile generation with jerk reduction.

You can run drive-based camming. You can run controller-based camming. You can use interpolation for smooth moves. You can do electronic shafting. You can do motion control synchronization. You can do master-slave motion like a pro.

What parts do you use?

You use these core parts. I use them too. I build them into our Jimi systems.

- Servo drives and motors

- Motion controllers with PLC motion

- Encoders and feedback devices

- HMI for camming

- SCADA

- Motion control software and cam editor software

- Simulation software and a digital twin

You connect with EtherCAT, PROFINET, Sercos III, Modbus, and OPC UA. You set position control, velocity control, and acceleration control. You watch precision, throughput, and efficiency.

You can use TwinCAT (Beckhoff) for Beckhoff electronic camming. You can use SIMOTION (Siemens) for Siemens electronic camming. You can use Kinetix (Allen‑Bradley). You can use Sysmac (Omron). You can use IndraMotion (Bosch Rexroth). You can use MELSERVO (Mitsubishi Electric). You can use SigmaLogic (Yaskawa). You can use Delta electronic camming. You pick. We help you fit. We help you tune.

Why not just use a mechanical cam?

A mechanical cam has limits.

- It wears.

- It has a fixed profile.

- It needs time to change.

- It needs parts.

- It can add design and manufacturing pain.

An electronic cam wins.

- You get flexibility and agility. You can do on‑the‑fly profile changes. You can load recipes.

- You get precision and accuracy. You can hold >99% positional accuracy with master encoder feedback.

- You get more throughput. You cut settling time. You speed cycles.

- You cut mechanical complexity. You have fewer parts. You have less wear.

- You get faster changeovers. You use digital adjustments.

- You save energy. You use optimized motion profiles.

- You get diagnostic capabilities. You do predictive maintenance.

- You see cost savings in long runs.

Where does it shine?

You can use electronic camming all over the plant.

- Packaging machinery: filling, sealing, labelling

- Printing presses and converting machines: registration and cut‑to‑length

- Material handling: pick and place robots, conveyor synchronization

- Flying shear and indexing applications

- Winding machine control and linear camming

- Food & beverage

- Textile and fabric

- Semiconductor and specialized assembly

When you need smooth motion profiles and reduced mechanical wear you need this. When you want faster changeovers and increased flexibility production you need this. When you want energy efficiency camming and cost savings you need this.

What do you need to set it up?

I guide you. I set a clear path. I make it simple.

- Design considerations: pick the right servo motor, servo drive, motion controller, and software

- Programming and configuration: use a cam editor and build an optimal cam profile

- Tuning and optimization: smooth the curve; balance acceleration and jerk; use S‑curve

- Integration: link with HMI, SCADA, Industrial IoT camming, and OPC UA

- Troubleshooting: we fix camming parameters, we fix ratio adjustment, we fix real‑time camming and dynamic cam profile changes

You can retrofit mechanical cams. You can upgrade to electronic camming. You can use open architecture camming. You can use vendor‑specific camming solutions. You can use system integration electronic cam. You can train your team with training electronic camming and best practices camming.

Data you can trust

I use data. I test. I measure. I improve. Here is clear data we see in the field. It matches industry 4.0 motion control goals.

Performance gains and wins

| Category | Metric | What you get | Source |

|---|---|---|---|

| Performance | Up to 30‑50% higher throughput | You use optimized motion profiles and cut settling time | Industry vendor reports and field use |

| Accuracy | 99% positional accuracy | You use high‑resolution encoders and clean servo control | Modern servo systems we build |

| Smoothness | 50‑70% jerk cut | You use Cycloidal and S‑curve profiles | Control theory and plant tests |

| Changeover | 50‑80% faster changeover | You load recipes in the HMI; no hard parts to swap | Machine builder results |

| Energy | 15‑30% energy cut | You lower peak torque; you use regenerative drives | Plant energy reviews |

| Maintenance | 20‑40% lower cost | You use fewer gears; you use diagnostics for predictive maintenance | TCO studies and customer feedback |

I also see a reduced mechanical footprint by 10‑25%. I see shorter builds. I see clean layouts.

Profile types at a glance

| Profile Type | Use | Note |

|---|---|---|

| Cycloidal | Smooth start and stop | Great for jerk reduction |

| S‑curve | Low shock | Great for light goods |

| Trapezoidal | Fast and simple | Easy to set |

| Modified Sinusoidal | Very smooth | Great for printing |

| Polynomial | Custom shape | Great for winding and indexing |

You can tune each one. You can set position, velocity, acceleration, and jerk to your need.

Jimi makes it easy

I build precision motion control with care. I build advanced motion solutions that fit you. I help you pick servo motor camming or stepper motor camming as needed. I match drive kinematics to your load. I use master encoder feedback for tight synchronization. I guide ratio adjustment. I set real‑time camming. I tune multi‑axis synchronization. I use digital camming technology and virtual camming when that helps you.

Need a strong, clean motion base? See our high quality electric linear actuators at this link: Electric Linear Actuators for smart motion.

Need tight servo moves for camming? See our servo motor actuators here: Servo Motor Actuators for precision camming.

Need plant ready gear? See our industrial automation actuators: Industrial Automation Actuators for packaging and converting.

Need brains for motion? See our smart actuator controllers: Actuator Controllers with HMI integration.

I design. I build. I test. I ship. I support. I do this so your machine builder can win.

Real jobs we help

- A pharmaceutical blister pack machine moved to electronic camming. It gained 35% speed. It cut changeover time by 80%. It cut waste by 20%.

- A high‑speed flying shear hit ±0.1 mm at 150 m/min. It cut scrap by 10%.

- A printing line held tight registration at high speed.

- A cut‑to‑length line gained clean edges.

- A filling machine gained accuracy and cut spills.

We match open platforms with your plant. We use OPC UA and EtherCAT with ease. We work with TwinCAT, SIMOTION, Kinetix, Sysmac, IndraMotion, MELSERVO, SigmaLogic, and Delta. We use SCADA camming integration for clear screens. We add HMI for camming with recipes. We do virtual commissioning camming. We use a digital twin to test. We fix issues fast. We ship lines fast.

How do we meet your needs?

You tell me your pain. I hear it. You see slow lines. You see long changeovers. You see wear. You see noise. You see scrap. You want smooth motion. You want precision. You want throughput. You want efficiency. You want trust.

I meet your needs with this plan.

- I map your loads. I set kinematics.

- I pick a clean cam profile.

- I set the gearing and the cam table.

- I tune acceleration and jerk for low shock.

- I test in a digital twin.

- I run virtual camming first.

- I do virtual commissioning.

- I go live.

- I watch predictive maintenance data.

- I train your team with training electronic camming.

You get a clear recipe. You get best practices. You get a plan for future of camming technology. You get a path to Industry 4.0. You get emerging trends motion control on your side.

Old cams vs new cams

Let me say it plain.

- The old way: mechanical cam. It is fixed. It wears. It is slow to change. It is hard to keep.

- The new way: electronic cam. It is flexible. It is precise. It is fast. It is low wear. It saves energy. It cuts costs. It boosts efficiency.

You see the win. You feel the win. You bank the win.

Your next step

You can start small. You can retrofit mechanical cams on one axis. You can use controller‑based camming first. You can add drive‑based camming next. You can bring in Industrial IoT. You can link to SCADA. You can add OPC UA. You can open your data. You can do predictive maintenance. You can scale. You can win.

I can do this for you. I can plan it. I can build it. I can ship it. I can stand by it.

Glossary and quick notes

- Electronic cam: software cam

- Mechanical cam: hard cam

- Master axis: leader

- Slave axis: follower

- Cam profile: move curve

- Cam table: move data

- Synchronization: move in time

- Interpolation: smooth move

- Trajectory generation: path build

- Electronic gearbox function: digital link

- Position control systems: set place

- Velocity profile generation: set speed

- Acceleration profile cam: set push

- Jerk: snap in motion

- S‑curve: soft edges

- Trapezoidal: simple step

- Cycloidal: very smooth

These small notes make each term clear. They help your team learn fast.

References

- Beckhoff, TwinCAT Motion Control Guides

- Siemens, SIMOTION Motion Control Docs

- Rockwell Automation, Kinetix Motion Control Guides

- Omron, Sysmac Motion Docs

- Bosch Rexroth, IndraMotion Notes

- Mitsubishi Electric, MELSERVO Motion Guides

- Yaskawa, SigmaLogic Motion Guides

- MarketsandMarkets, Motion Control Market Trends

- Mordor Intelligence, Motion Control Market Outlook

Final word

You want clean motion. You want clear wins. You want fast change. You want safe lines. You want trust. Electronic camming makes it real.

I am here. I am Jimi. I bring experience, expertise, authoritativeness, and trustworthiness. I craft industrial automation systems that work. I fit position control, velocity control, acceleration control, and jerk to your task. I tune multi‑axis synchronization. I push precision. I raise throughput. I protect efficiency. I stand by you.

Let’s build your next move.