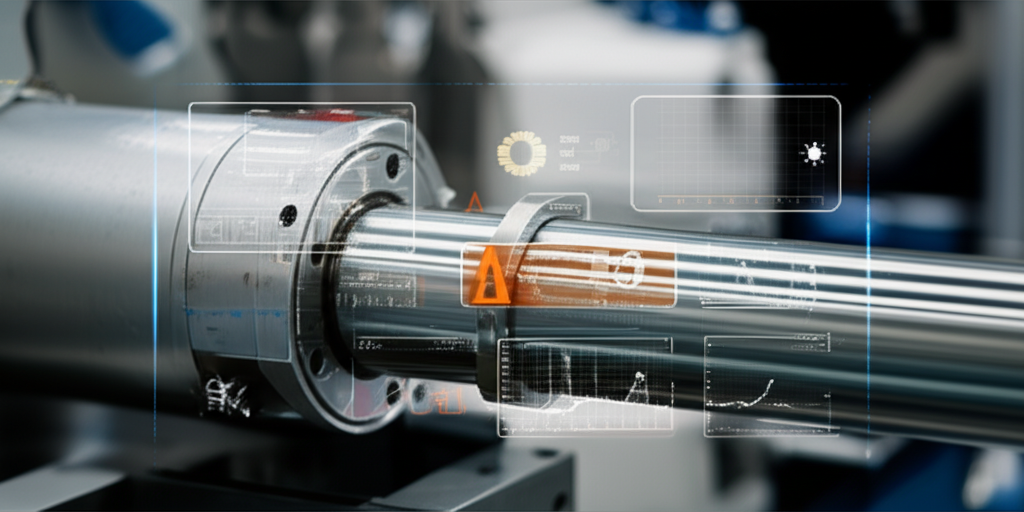

Unlocking Innovation: Why Custom Linear Motion Solutions Are Essential for Special Applications

When Off-the-Shelf Simply Isn't Enough

Picture this: you’re deep into a big engineering project. You order a linear actuator or a motion stage, confident it’ll fit where you need it. Then you open the box—only to find that one key corner won’t clear your system’s frame by less than a millimeter. Or you fire it up and realize the off-the-shelf model shakes at high speed or can’t handle the extreme heat or cold your process requires. Now, you’re spending hours trying to make a generic component work in a world where nothing about your application is “average.”

This headache is everywhere. Medical diagnostics, aerospace controls, semiconductor handling, advanced robotics, and specialized test benches all challenge “standard” solutions. They need bespoke linear stages, precision linear actuators, and customized automation solutions built just for them.

Custom linear motion isn’t about fancy add-ons—it’s about survival in niche fields. Can a basic actuator survive a deep vacuum at -100°C or hold its own in a Class 1 cleanroom? Will it keep that wafer aligned within 30 nanometers, time after time? Not likely.

Custom solutions bring three big wins:

- Optimized performance for high-precision linear motion

- Compact designs that use each millimeter of space

- Extreme reliability and a longer working life

With these, you stop wrestling with parts and start controlling your world.

Understanding the Gaps: Why Generic Solutions Fail

Precision, Payload, and Speed Constraints

Standard actuators look good on paper until you stress them with real-world loads. As errors add up, application-specific accuracy falls apart. If your payload is heavy or awkwardly shaped, the lack of high rigidity linear guides turns “precision” into guesswork.

You might need high-speed linear motion or a unique speed/acceleration pattern—a “motion profile” as distinct as a fingerprint. Off-the-shelf parts can’t match your script, so you’re stuck with workarounds that eat up time and money.

Environmental Hostilities and Compatibility Issues

Not all actuators play nice in tough spaces. Vacuum linear motion brings outgassing issues with poor material choices. In a cleanroom linear system, basic grease or plastic spells contamination. High or low temperatures, corrosive splashes, or radiation? Standard parts weren’t made for that battle. You’ll deal with material compatibility headaches, lubrication nightmares, and hardware that ages fast.

Integration, Footprint, and Longevity

A one-size-fits-all design ignores your real-world constraints. Can you fit that actuator into a tight enclosure, or lay it flat inside a thin robotic arm? Probably not. Business-critical automation needs compact linear motion solutions with exact footprints. And if your system runs non-stop, a standard actuator might fall apart at the seams. Over time, those failures add up, costing you real money and forcing stops you can’t afford.

Where Precision Customization Becomes Indispensable

Precision isn’t a luxury in the industries we serve—it’s a job requirement. Let’s explore where custom linear motion leads the way.

Medical & Life Sciences

Surgeons trust robots for millimeter-perfect moves. Labs need quiet operation and biocompatibility in their equipment. Diagnostic tools require the kind of steady, clean, repeatable motion that generic components just can’t deliver.

- Surgical robotics

- Laboratory automation

- Drug discovery platforms

All these depend on ultra-precision linear stages and custom gantry systems. Even the tiniest vibration can throw off results or compromise safety.

Semiconductor & Electronics Manufacturing

Here, the game is fast and precise. Handling a wafer at nanometer scale inside a Class 1 cleanroom is business as usual. A small misalignment in chip bonding or inspection equipment linear platforms means defects or scrap. Custom solutions allow you to push limits on speed, accuracy, and cleanliness.

Aerospace & Defense

Satellite positioning and onboard systems need vacuum compatibility, light weight, and shock/vibration resistance. An actuator must survive massive temperature swings and relentless shaking, all while hitting targets exactly. Any slip isn’t just a nuisance—it could cost millions.

Industrial Automation & Special Machinery

Whether it’s large-scale assembly, additive manufacturing, or material handling, every application wants heavy loads moved far, fast, and often in rough conditions. Downtime—or poor fit—burns profit. With application-specific linear motion, you build uptime, not just output.

Research & Scientific Instruments

Physicists and chemists push past the possible every day. Microscopy stages, particle accelerators, and custom prototypes all need accuracy measured in fractions of a micron, often in unique layouts or wild conditions. Only a solution as unique as their experiment will work.

From Concept to Commissioning: The Custom Journey

We at Jimi Technology don’t sell you a product off the shelf and say “good luck.” Our process is about partnership—from your first sketch to a running system.

Requirements Definition & Feasibility Study

It starts with questions. What temperature range? How clean must it be? What about shocks, or odd load shapes? We gather every detail for a true custom engineered motion profile. We size up risks and outline the project.

Conceptual Design & System Architecture

Using CAD software like SolidWorks or AutoCAD, we map options and simulate performance. Which servo motors, ball screws, bearings, and guides work best for your footprint and goals? We predict problems before they happen.

Detailed Engineering & Prototyping

Every piece—drive, sensor, bracket—gets checked. Imagine a high-force actuator for a surgical robot. We choose biocompatible alloys, compress the package, double the force, and keep the weight down. We 3D print or machine prototypes, keeping the leap from digital to physical clean and precise.

Testing, Validation, & Optimization

You can’t cut corners here, not if you want parts to last. We test repeatability with nanometer stringency. We run systems through environmental extremes (think vacuums, thermal cycling, or radiation exposure) to check if they measure up. Only then do we approve full production.

Manufacturing, Assembly & Integration

After all checks, we build with ISO 9001 certified processes. Our team keeps every actuator, rail, and stage clean, sealed, and ready for integration into your line. We support installation, debug with you on site, and stay until it’s right.

Engineering Excellence: What Sets Custom Solutions Apart

Precision, Accuracy, & Repeatability

You want less than a human hair’s width of error. We deliver by pairing the right bearings, drives, and feedback encoders. Smart electronics and tight software control make each move count—down to the micron, or even nanometer.

Environmental Resilience

Got a harsh workspace—chemical washdowns, high vacuum, radioactive conditions? We look past the usual metals, build with advanced composites or sealing steps, and spec lubricants that survive where petroleum or silicone fails.

Load Capacity & Stiffness

Want to move a two-ton beam or hold still while imaging single cells? Our custom designs use smart geometry, optimized bearing configurations, and rock-solid frames for strength without the bloat.

Dynamic Performance (Speed, Acceleration, Throughput)

Some processes need motion so fast it’s a blur. Others want smooth, controlled ramps. We tune motor sizing, drive types, and control loops so you hit your mark—every time, with no overshoot.

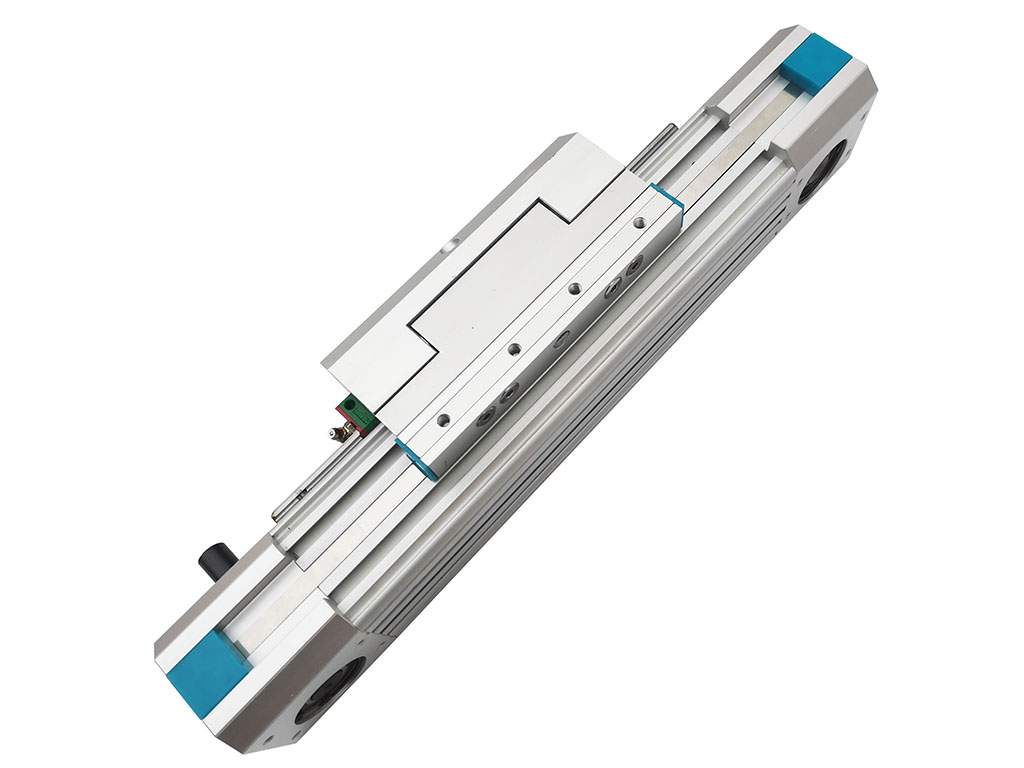

Footprint, Weight, and Maintainability

Space gets tight. Mobile gear needs every gram cut. We design for compactness, simplicity in service, and long-lived, low-maintenance performance. That’s how your investment keeps earning, cycle after cycle.

Why Partnering with a Custom Linear Motion Expert Matters

Let’s face it: Not every supplier speaks your language. At Jimi, we don’t just make products—we offer solutions.

Deep Engineering Acumen & Cross-Industry Experience

Our team includes specialists in mechanics, electronics, and controls, drawing on years of mechatronics and precision engineering for industries from semiconductors to defense. Each project expands our playbook.

Advanced Manufacturing & Testing Capabilities

Our in-house tools mean we can machine, assemble, and stress-test parts to the highest standards. Cleanrooms, climate chambers, and all the latest tech work for your build. Certifications like ISO 9001 show our seriousness.

Risk Mitigation & Cost-Effectiveness

Problems get fixed early so you don’t pay later. And though custom builds might cost more at first, less downtime and smarter performance mean big savings on maintenance, energy, and scrap over time.

Ongoing Support & Future-Proofing

You don’t want a supplier who waves goodbye after project handoff. We stay on board, supporting upgrades, maintenance, and changes so you’re ready for tomorrow’s needs. It’s not just about today—it’s about lasting value.

Selecting Your Partner for Innovation

Not all providers are equal. Here’s a checklist when choosing your custom motion partner:

- Expertise & Track Record: Do they deliver in your field? Ask for success stories in semiconductor, aerospace, research—real testimonials.

- Capabilities: Can they handle design, build, and test all in-house? Are they versatile, working with electric cylinders, servo motor actuators, or ball screw actuators as the job demands?

- Collaboration: Do they involve you throughout? Are milestones clear? Fast response and open dialogue matter.

- Quality & Standards: What’s their approach to certification? ISO 9001? Cleanroom practices? These prove their commitment.

- Support: How do they handle installation and long-term care? Look for clear service agreements and a track record of post-sale support.

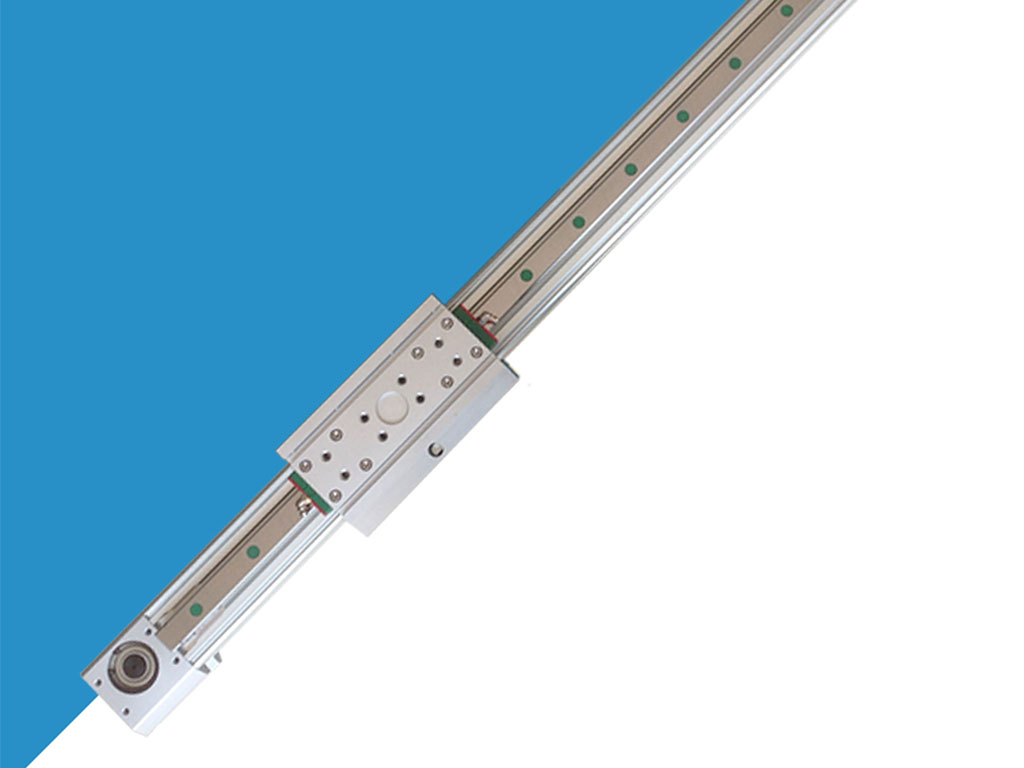

For examples of robust, proven linear solutions, check out our Electric Linear Actuators, Servo Motor Actuators, and Ball Screw Actuators. Find even more specialty designs at our Industrial Linear Actuators and Rodless Actuators pages.

The Future of Advanced Automation Relies on Custom Solutions

Here’s the bottom line: Off-the-shelf parts can’t keep up with the pace of special applications. True innovation in aerospace, medical, research, or industry means custom linear motion solutions—built with your exact challenge in mind.

You need a partner, not just a product. At Jimi Technology, we’re ready to engineer and deliver the reliability in motion and precision that sets your project apart from the pack.

Ready for a motion solution as unique as your application? Contact our experts today. Let’s help you leave the headaches behind and push boundaries no “standard” solution ever could.

Discover more about our custom motion solutions and see how Jimi can unlock innovation on your next project. Your challenge is waiting. So are we.