Hello, Friend! Let’s Fix That Linear Actuator Together

Is your linear actuator not moving? Do you hear a funny noise, or see your favorite chair stuck in the wrong spot? Maybe the TV lift will not come down. You are not alone! I know how tricky actuators can be. But I also know you can fix many problems by yourself. I will show you how, step by step. You will save time, money, and maybe your day!

If you want to know more vedioes about linear motors and electric cylinders, you can go to visit our Youtube Chanel.

I am from Jimi Technology Co., Ltd. We make the best linear actuators, TV lifts, and all sorts of automation tools. Our products help you push, pull, tilt, or raise any object with just a button. We do not just sell things. We solve your problems and help you get the most out of your machines.

What Is a Linear Actuator?

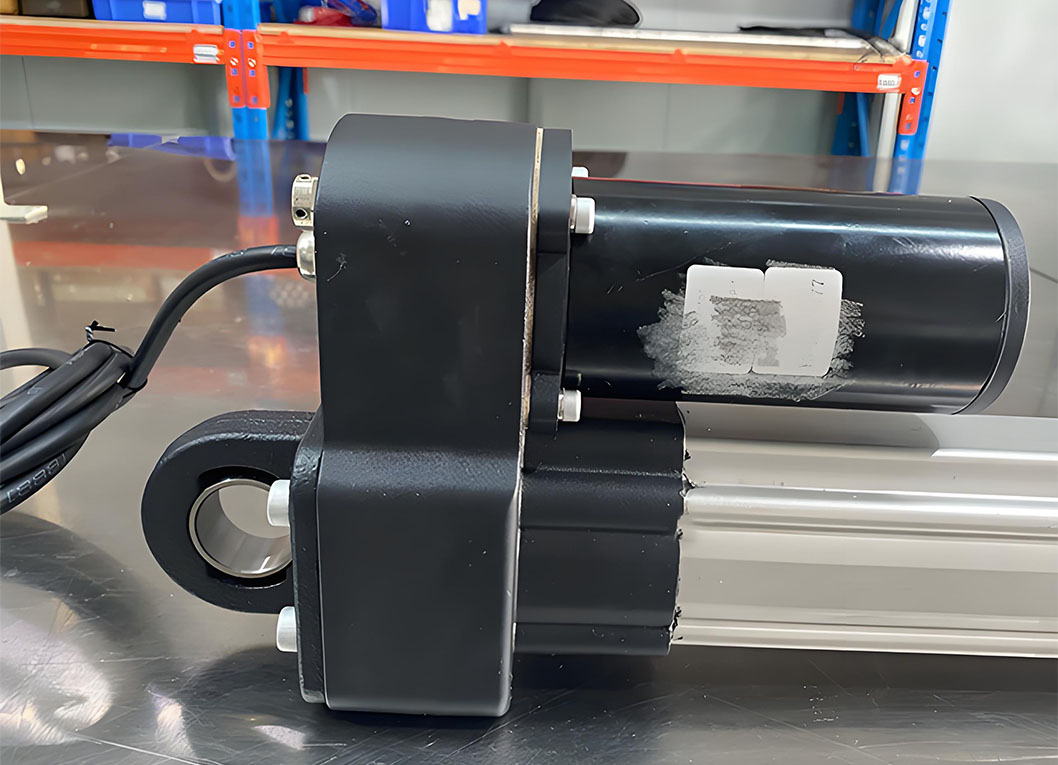

A linear actuator is a smart tool. It turns electricity into motion in a straight line. This means you can move heavy things up and down, in and out, fast or slow. A TV lift uses a linear actuator. So do beds, desks, doors, even robots!

Key Parts of a Linear Actuator

- Electric Motor

- Lead Screw

- Gearbox

- Limit Switch

- Rod

- Housing

- Wires

- Mounting Brackets

- Wiring Diagram

When you press a switch or remote, the actuator responds. The controller tells the actuator to go in or out. The limit switches tell it when to stop.

Why Troubleshooting Matters

If your actuator stops, you lose time. Maybe a bed will not move, or your solar panel won’t turn. You want a quick fix now—not next week! When you learn how to troubleshoot and fix your actuator, you:

- Save money on repairs

- Shorten downtime

- Learn new skills

- Make your machines last

Stay Safe!

Before you touch anything, turn off the power. Make sure your hands are dry. Never open an actuator that is plugged in. Some parts can pinch. Always follow the steps.

Common Actuator Problems & Reasons

You might see or hear different troubles. Here are the top ones, what causes them, and how you spot them.

Problem Table

| Problem | Cause | What You See/Feel | Easy DIY Fix |

|---|---|---|---|

| No Movement/Power | Bad power, loose wire | Nothing moves | Yes |

| Humming/Clicking, No Move | Jammed rod, stripped gear | Noise, still stuck | Sometimes |

| Slow or Weak Movement | Low power, dry gears | Moves, but slow/weak | Yes |

| Grinding Noise | Worn gears, bent screw | Bad noise, shaky move | Sometimes |

| Overheating | Running too much | Feels hot, shuts down | Yes |

| Won’t Fully Retract/Extend | Bad limit switch | Stops too soon | Yes |

| Erratic Operation | Loose wires, bad controller | Works, then fails | Yes |

Source: Jimi Technology industry analysis, 2024.

Step-by-Step Troubleshooting: Let’s Get to Work!

Here’s how I check and fix a broken linear actuator. Follow these steps and watch your problem disappear.

- Look and Listen

- Are wires loose?

- Is something hot, melted, or broken?

- Does it try to move but cannot?

- Check the Power

- Turn off the unit.

- Use a multimeter. Is the voltage right? Most units need 12V or 24V.

- Plug in a different power supply if you can.

- Look for blown fuses. Replace any you find.

- Examine the Wires and Controller

- Gently tug wires. Do they pop out? Fix any loose ones.

- Bypass the switch to see if the motor starts.

- Open the controller board. Burn marks mean you might need a new one.

- Move Without a Load

- Remove heavy things from the actuator.

- Try it all by itself. Does it work now?

- Grease the lead screw and rod. Use a safe oil or grease.

- Inspect the Motor and Gears

- Listen for buzzing, clicking, or grinding.

- Briefly touch power to the motor only.

- Open the housing if you know how (some need tools). Are gears stripped or worn? New gears can bring it back to life.

- Test Limit Switches

- Manually press the switch. Does it click and stop?

- Adjust or replace if needed.

- Make sure nothing blocks the rod.

- Stop Overheating

- Let it rest. Never run more than the duty cycle.

- Lower the load. Heavy things make it work too hard.

- Place the actuator somewhere there is airflow.

Table: Common Causes & DIY Power

| Issue | Percent of Cases* | Easy DIY? | Typical DIY Savings |

|---|---|---|---|

| Power/Wiring | 30–40% | Yes | $50–$500 |

| Jam/Obstruction | 20–25% | Yes | $75–$300 |

| Slow/Weak Move | 15–20% | Yes | $50–$200 |

| Noise/Wear | 10–15% | Sometimes | $75–$300 |

| Overheating | 5–10% | Yes | $100–$500 |

| Limit Switch | 5% | Yes | $20–$100 |

Source: Jimi Technology after-sales records and forums, 2024.

Simple DIY Tools You Will Need

- Small screwdriver

- Multimeter

- Needle nose pliers

- Grease or light oil

- Safety glasses

Don’t Just Fix—Prevent! Simple Tips for a Long Life

Keep your actuator happy, and it will work hard for years.

- Clean dust and dirt often.

- Lubricate the rod, lead screw, and gears as directed.

- Don’t go beyond the actuator’s limit. Too heavy a load can break it.

- Respect the duty cycle. If the book says “run 10 minutes, rest 2 minutes,” follow it.

- Inspect wires and brackets. Fix them before they get worse.

Want to see a full checklist? Check our Preventative Maintenance for Linear Actuators guide!

Sometimes, You Need to Repair or Replace

Fixing is usually easy. But sometimes the problem is too big, or parts are very old. Ask yourself:

- Is the cost to fix more than half the price of a new actuator?

- Is the actuator older than its expected lifespan?

- Are parts hard to find?

If yes, you might need a new unit. That’s where Jimi Technology shines. We offer a full range of Electric Linear Actuators, from light-duty for home projects, up to Heavy-Duty Linear Actuators for industry.

Why Choose Jimi for Your Next Actuator?

- Trusted: We are a top China Linear Actuator Manufacturer.

- Expert: We help with every step, from picking parts to guiding you on repairs.

- Complete Range: Need servo motor actuators? Try our Servo Motor Actuators for precise jobs.

- Support: Our team is always here to answer, fast.

Many customers just like you have solved their DIY actuator repair problems with our help. They save money, keep projects moving, and never get left in the dark.

Let’s Wrap It Up – You’re Now the Troubleshooter!

Remember, most actuator problems have simple DIY fixes. Look for bad power, stuck rods, or dry gears first. Try every tip above, step by step. Most of the time, your actuator will be as good as new!

And if you ever want an upgrade, need a new part, or crave a smoother, quieter system—visit us at Electric Linear Actuators or talk to your China Electric Cylinder Factroy expert. We are here for you.

References

- Jimi Technology Co., Ltd. Customer Service & Technical Support, 2024.

- Industry study: Linear Actuator Maintenance Best Practices, 2023.

- User forums: Automation DIY, HomeTech 2023-2024.

Want more? Check out our guides for Industrial Automation Actuators and DIY Projects & Robotics Linear Actuators for more fun, simple ideas.

Let’s Make Your Machines Work, Together!

No job too big. No jam too tough. With Jimi, you fix it right, every time.