Introduction: The Big Change in Factory Motion

Do you want things to work better, smoother, and cleaner? Old cylinders, like pneumatic and hydraulic, can be noisy, leaky, and hard to control. Many factories have used them for years. But now, there is something better: electric actuators. These tools use electricity to move things up, down, push, or pull with just the press of a button.

At Jimi Technology Co., Ltd., we help people move into the future. With our high-quality electric actuators and smart automation systems, you get easy motion, clean operation, and safe workspace. In this guide, I will show you how you can switch from old cylinders to electric actuators, improve your machines, and save money.

Why Make the Switch? The Clear Benefits of Electric Actuators

You need tools that work well every day. Old cylinders can break, need a lot of air or oil, and make loud sounds. Here is why electric actuators are a smart choice:

- Super Control and Accuracy

- You can stop, start, and change direction—fast.

- Move to any spot you want (multi-position control) with repeatability.

- Use programmable motion profiles to set the speed, force, and position.

- Great for delicate jobs where tiny movement matters.

- Save Energy and Money

- No more wasting energy on compressed air or hydraulic fluid.

- Lower costs because you use only the power you need.

- Need less fixing and have fewer breakdowns.

- These actuators can last over 10 years!

- Work Quietly and Cleanly

- No hissing air or messy oil leaks.

- Cleaner machines are better for making food or medicine.

- Quiet operation is gentle on workers’ ears.

- Better for People and the Planet

- Little noise makes it safer and more comfortable.

- No leaks, so no danger of slipping or contamination.

- Uses less energy, so the earth is happier too.

- Quick Change and Smarter Factories

- Change jobs with a few taps—no wrenches needed.

- Works with Industry 4.0, IoT, and smart computers.

- Easy integration with robotics and modern control systems.

Let’s Compare: Why Electric Actuators Win

Here’s a simple table. It shows how electric actuators beat pneumatic and hydraulic cylinders:

| Feature | Pneumatic Cylinder | Hydraulic Cylinder | Electric Actuator |

|---|---|---|---|

| Energy Efficiency | 15-25% | 40-60% | 80-90% |

| Precision | ±0.5-5mm | ±0.1-0.5mm | ±0.005-0.05mm |

| Maintenance | High | High | Low |

| Noise | High | Moderate/High | Very Low (<60dB) |

| Cleanliness | Leaks & Dust | Oil Leaks | No Leaks, Clean |

| Setup Time | Medium | Medium | Fast (software) |

| Lifespan | 2-5 years | 5-10 years | 5-15+ years |

| Cost Savings | Low Energy, High Fixes | Oil Cost, High Fixes | Saves $20,000+/year |

| Best For | Simple Moves | Heavy Loads | Precision, Clean, Quiet |

References:

Tolomatic Case Study, Bosch Rexroth Application Story, Parker, Festo, Industry Reports

How to Change: Step-by-Step from Cylinder to Electric Actuator

Are you ready to say goodbye to old cylinders? Here is a simple plan.

Step 1: Look at What You Need

- How heavy is your load?

- How far and how fast should it move?

- How many times will it move each day?

- What special needs (temperature, dust, clean room) are there?

Step 2: Pick the Right Electric Actuator

- Choose the type: Rod-style, Rodless, Ball Screw, or Roller Screw Actuators.

- Get the right motor: Stepper motors for simple moves, servo motors for high-precision.

- Pick the size using actuator sizing software—don’t go too big or too small.

- Think about communication: PROFINET, EtherCAT, or Ethernet/IP for connecting to your PLC.

Find the perfect actuator for your need at our China Linear Actuator Manufacturer page.

Step 3: Install the Actuator

- Remove your old cylinder carefully.

- Mount the electric actuator with right brackets.

- Double-check alignment for smooth motion.

- Manage cables neatly to avoid tangles.

Check out our mounting brackets and actuators with position feedback.

Step 4: Connect the Wires & Program

- Wire the actuator to the power supply.

- Set up the controller or PLC with simple software.

- Use the HMI for easy start, stop, and speed changes.

- Tune for best motion—get perfect results.

Step 5: Test and Train

- Run the actuator and watch for smooth moves.

- Check if the position is just right.

- Teach your team how to use the new system.

What to Watch For

Not every job is the same. Here are some things to remember:

- Size right: Too big wastes power, too small breaks fast.

- Check the room: Hot, cold, wet, or dusty? Choose the right actuator.

- Match controls: Make sure it works with your PLC or HMI.

- Know your budget: Electric actuators save money over time, so check your return on investment.

Want to see more about industrial automation actuators and special solutions? Visit our site!

Real Stories: See the Results!

Factories everywhere trust Jimi’s electric actuators. Here are some wins:

- Packaging Plant: Switched out 15 pneumatic cylinders. Saved over $20,000 a year in energy. Changeover time went from 30 minutes to 5 minutes.

- Car Parts Maker: Replaced hydraulic press. Now gets perfect position every time, less than 0.01mm off. No more oil leaks.

- Food Producer: Uses our clean, quiet actuators—no risk of spills. Meets all food safety rules.

- Medical Device Company: Needs super clean and exact moves. Electric actuators hit the mark every time.

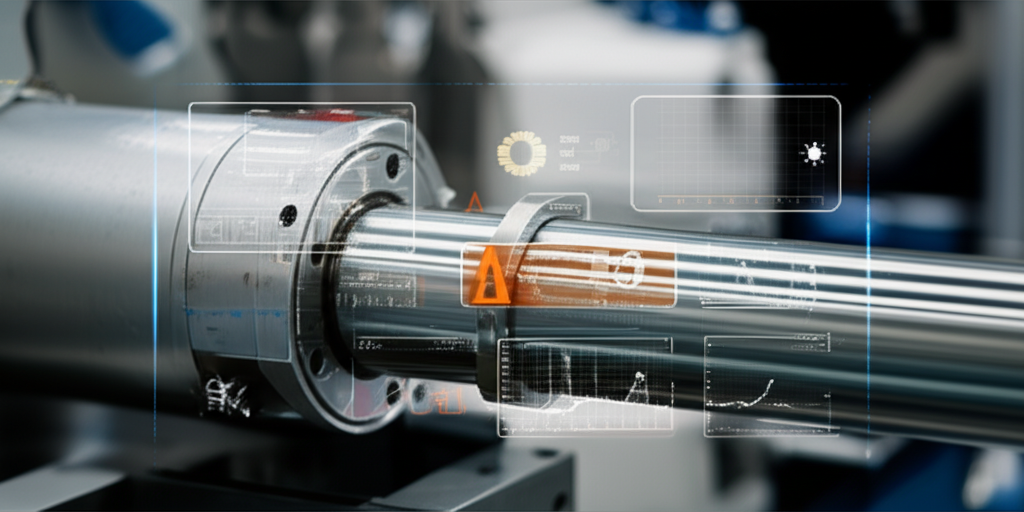

The Future: Smarter, Safer, Better

Electric actuators are getting even smarter. Some now have sensors that tell you when to grease or fix them—predictive maintenance. Others connect right to your phone or computer, so you can watch them work from anywhere.

At Jimi, we are always bringing out new features, like real-time data, digital twin technology, and advanced diagnostics. This helps you work faster and smarter.

Why Choose Jimi? Your Best Partner in Motion

At Jimi Technology Co., Ltd., we do more than sell actuators. We help you plan, choose, set up, and support your new systems every step of the way.

- Over 10 years making electric actuators, TV lifts, and automation solutions.

- Experts in precision control actuators, ball screw actuators, and servo electric actuators.

- Trusted by big names in food and beverage, medical, packaging, and automotive manufacturing.

- Clean, quiet, and long-lasting tools that save you money and help the planet.

See all our latest electric linear actuators and how they fit your need.

Take the Next Step: Upgrade with Confidence

You want smoother work, less waste, and more control. Now is the time to move up from old cylinders to electric actuators. With Jimi, you get expert help, top products, and lasting support.

Ready to start? Get in touch with our China electric cylinder factory to talk to a real engineer, see solutions, and unlock better automation today.

References:

- Parker, Festo, Tolomatic, Bosch Rexroth, Industry Benchmarks

- China Electric Cylinder Factroy

- Internal data from recent Jimi customer case studies

See More: