Do you need an actuator for a hot or cold place? That’s a big job. At Jimi (Jimi Technology Co., Ltd.), we make actuators that can work in many tough spots. We know what you need and how to help.

Let us tell you why picking the right high temperature actuator or low temperature actuator is so important. If you use the wrong one, it can break, get stuck, or even leak. That means lost time, trouble, or even danger. Let's learn how to stay safe and smart with your choice.

Why Extreme Temperatures Are a Big Deal

Extreme heat or very cold can do bad things to machines.

- High heat actuators can get too hot. Metal parts can bend or get soft. Seals can melt.

- Low temperature actuators feel the freeze. Some parts crack or get stiff.

- Both cryogenic actuators and harsh environment actuators live in the tough zone.

- If you pick the wrong actuator, it might fail. When that happens, work stops. Or worse, something breaks and people might get hurt.

“Extreme temperature” means anything too hot or too cold for normal machines. For example:

- Hot: Over 150°C (like in a furnace valve or steam turbine)

- Cold: Below -40°C (like cryogenic systems or cold storage automation)

What Happens to Actuators in Hot or Cold Places?

Let’s look at what can go wrong:

- Materials

- Thermal expansion: Metal or plastic parts change shape when hot or cold. Things can stick or not fit right.

- Material degradation: Softening, cracking, or melting can happen.

- Corrosion: High temps make rust worse.

- Some materials work better than others. For example:

- Use austenitic stainless steel in cold

- Use superalloys in high heat

- Seals and Gaskets

- Seals keep oil in and dirt out.

- In hot spots, elastomer seals (like FKM, FFKM) might melt—use metal bellows.

- In the cold, PTFE or silicone can stay soft.

- Lubrication

- In hot: Oil breaks down fast or burns away.

- In cold: Grease gets thick and sticky.

- Pick the right lube:

- Synthetic oils stay slick in the cold

- Dry film lube (like MoS2) helps in the heat

- Electronics & Wiring

- High heat can break wires or chips in electric actuators.

- Cold can crack insulation or make poor connections.

- Mechanical Parts

- Bearings might crack in cold or wear out fast in the heat.

Table 1: How Extreme Temperatures Hurt Actuators, and How We Solve It

| Problem | What Happens? | Jimi Solution | Success Story |

|---|---|---|---|

| Seal Degradation | Seals melt, crack, leak | Special FFKM, PTFE, metal bellows | 10x longer life in furnace |

| Lubricant Fails | Oil burns or thickens, actuator seizes | Synthetic grease, internal heaters | Runs smooth at -50°C |

| Materials Crack | Metal or plastic parts snap | 304L steel, Inconel, smart composites | No cracks at -196°C |

| Electronics Fail | Chips and wires break in heat | Heat sinks, insulation, remote electronics | Zero signal lost in desert |

How To Pick the Best Actuator for Hot or Cold Jobs

Let’s keep it easy. Here are five big things you must check:

- What is the real temperature?

Is it always hot or cold? Or does it change a lot, like a thermal cycling system?

- What type of actuator do you need?

- Pneumatic actuators: Use air, good for dusty hot spots and some cold jobs.

- Hydraulic actuators: Use oil, strong but the oil can break down in heat or freeze in the cold.

- Electric actuators: Need good thermal management for high or low.

You may want to see our Electric Linear Actuators for smart, safe motion.

- What materials are in the actuator?

- Housing, shaft, piston, gears—what are they made from?

- Match them to your temperature. In the cold, use stainless steel. In the heat, superalloys rock.

- How are the seals made?

- If you need special gaskets or O-rings, pick from our big list. Metal bellows for super hot, PTFE seals for super cold.

- Power source and safety

- Is your power steady and safe?

- For dangerous spots, check IP rating or ATEX certification.

Cool Real-Life Examples

High Temperature Work

- Glass factory furnaces: Need heavy-duty, high temperature actuators for dampers.

- Oil & gas rigs: Actuators on downhole tools see big heat and pressure.

- Power plants: Steam valves must stand up to hot and wet for many years.

Cryogenic/Cold Applications

- LNG plants and storage: Very cold. Standard seals freeze—use our custom cryogenic actuators.

- Refrigerated warehouses and trucks: Automation must always work, even at -50°C.

Need more ideas? See how our Heavy-Duty Linear Actuators keep working no matter the weather.

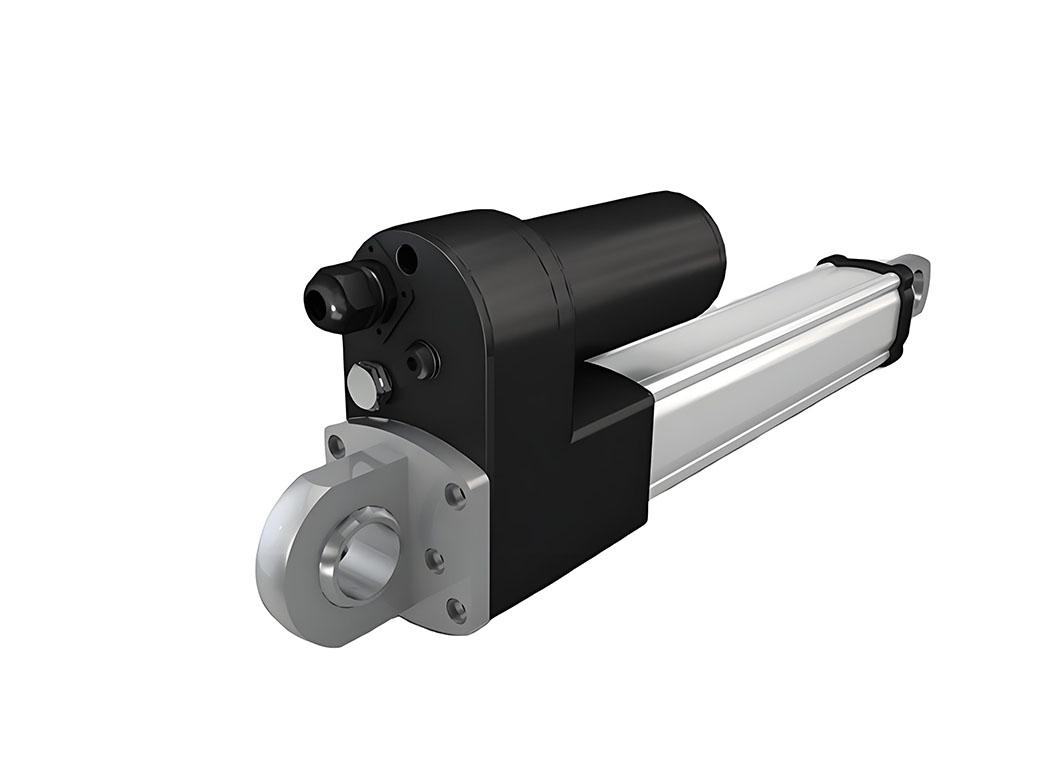

What Makes Jimi Actuators Special?

At Jimi, we don’t just make actuators—we solve your problem. We have:

- Linear actuators, TV lifts, rodless actuators, and more.

- Lots of materials and parts choices—like metal bellows or custom elastomers.

- Smart design: Handles thermal expansion, shock, and corrosion.

- Testing: We pre-test every actuator to make sure it works at your temperature.

- Predictive maintenance: Sensors built in. We tell you before trouble starts.

Our strengths:

- Fast answers from our experts

- Custom designs for any job

- Long life and safe work

- Big range: Stainless Steel Actuators, Waterproof Linear Actuators, Actuators with Position Feedback

If you want something special, just ask. We build what you need.

How To Keep Your Actuator Happy

- Install it right: Stops thermal stress before it starts.

- Test before use: Try it in high or low temp (we help with pre-checks).

- Inspect often: Look for leaks, weird sounds, odd moves.

- Talk to us: We're here for advice, troubleshooting, or upgrades.

Table 2: Pick the Right Actuator Based on Your Conditions

| Condition | Best Actuator | Why Choose This? | Jimi Product to Try |

|---|---|---|---|

| High Heat (>200°C) | Pneumatic or custom electric | Handles heat, needs few seal changes | Industrial Linear Actuators, Ball Screw Actuators |

| Super Cold (<-50°C) | Hydraulic or electric | Special seals, stays strong | Heavy-Duty Linear Actuators, Cryogenic Kits |

| Thermal Cycling | Servo motor or ball screw | Deals with size change | Servo Motor Actuators, Ball Screw Actuators |

| Dusty/Dirty | IP68-rated actuators | Stops dirt and water | Waterproof Linear Actuators, Stainless Steel Actuators |

Why Trust Jimi?

We are not just a seller. Jimi is a trusted company in the world of automation. We have real world skills, strong solutions, and many happy customers.

- All actuators pass strict tests for dust, vibration, high pressure, and more.

- Our designs help you avoid failure, save money, and stay safe.

- Customers love our help—quick, clear, and always expert.

Want to know if an actuator will last? We use smart predictive maintenance and long-life designs. You get less downtime, and more uptime.

Jimi: Your Expert Partner in Extreme Temperature Work

Are you ready for easy automation in hard places? Do you want your machines to keep moving, even in the toughest heat or cold? Start with Jimi.

Explore our China Linear Actuator Manufacturer, Electric Cylinders, or Stainless Steel Actuators today. Our know-how, top parts, and careful testing make us your best choice.

Need help? Contact Jimi now—let us make your job simple and your result strong.

References

- Jimi Technology Co., Ltd. internal product test results and field case studies.

- Industry standards for actuator selection: IECEx, ATEX, IP68 ratings.

- Data compiled from users in glass, oil & gas, LNG, and industrial processing plants.

We use the best ideas, the best designs, and bring them right to you. That's why customers who need actuators for extreme temperatures come to Jimi—every time.