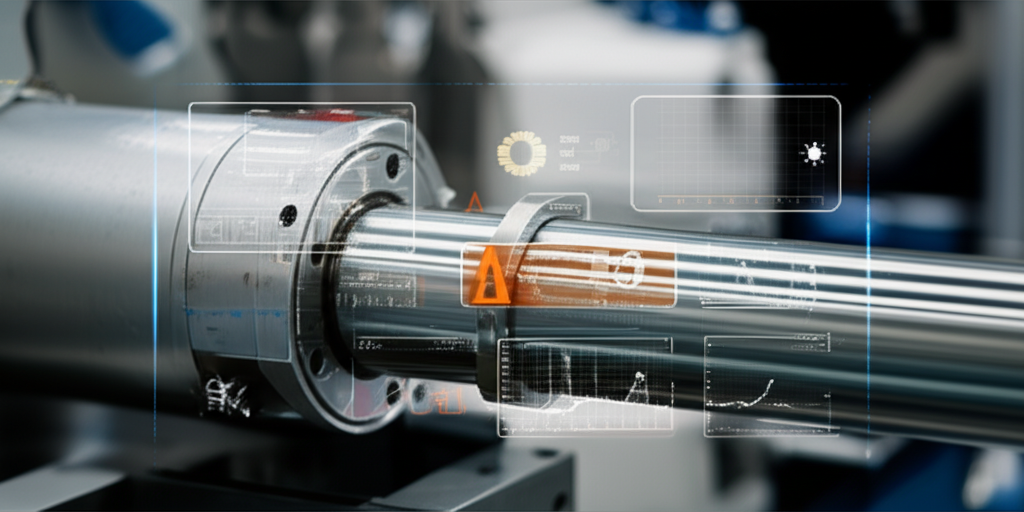

Do you need something special? Off-the-shelf linear actuators may not be enough for your job. Some jobs need more. Sometimes you want more power, a smaller size, or a smart actuator for a tough spot. Not every motion problem is the same. That’s where custom, non-standard linear actuators come in. At Jimi Technology Co., Ltd., we lead the way. We make bespoke linear actuators for all your tricky jobs. You press a button—our actuator does the lifting, the pushing, or the pulling. That’s smart, simple, and strong.

What Are Custom, Non-Standard Linear Actuators?

Every machine moves in a special way. Sometimes, you can’t buy the right part in a store. So, you need a part made just for you.

Beyond Off-the-Shelf: Defining Customization

Custom electric actuators are different. Standard actuators come in standard sizes and shapes. They have set stroke lengths and speeds. Sometimes that works. But what happens when your robot needs a tinier part, or your lab needs precision custom actuators to move in tiny steps? That’s when custom steps up. We listen, we design, and we build—just for your project.

Key Characteristics of Tailored Actuation

You get to pick:

- The stroke: Long or short, you choose.

- The force: Do you want strong like a gorilla or gentle as a feather?

- The speed: Fast like a rabbit or slow like a turtle.

- The shape: Skinny, short, or even waterproof.

- Added brains: Want feedback control or an integrated controller? It’s yours.

- Materials: Need stainless steel for harsh conditions? No problem.

Why Choose Custom? The Advantages of Tailored Linear Motion

Let’s ask: Why custom? Why not just buy what’s ready?

Unmatched Performance for Demanding Applications

Custom actuators give you the best fit, every time. You get:

- Precision: They can move as little as one micron at a time. That’s smaller than a hair! You need this in medical devices or lab tools.

- High force in tight spaces: Want more in less? Custom is how you get it.

- Smooth speed and long life: No overheating, no funny noises. Only smooth motion.

Solving Unique Design and Environmental Challenges

Think about where your actuator will live:

- Space is tight? We fit in.

- Is it too hot, too cold, very wet, or full of dust? We use special seals, stainless steel, and corrosion resistant materials.

- Is your actuator for a rocket or a food factory? Each place has its own “right” part.

Enhanced System Integration and Reliability

Want your actuator to play nice with other machines? We help them work together. No surprises. We make integration simple, with less wiring and easy setup.

Cost-Effectiveness in the Long Run

You may spend a little more at the start. But you save on repairs, downtime, and wasted time. Over five to ten years, you can cut the total cost by up to 30%! That’s real value.

When Do You Need a Custom Linear Actuator?

Performance Requirements Exceeding Standard Specifications

Sometimes your job is more than a catalog part can handle:

- Need high force in a tiny package?

- Very long strokes for a lab tool?

- Or do you need perfect repeatability and accuracy, as in a servo linear actuator or stepper linear actuator built just for you?

Environmental Extremes and Specialized Conditions

- Is your machine in a cleanroom, under the sea, or in a vacuum?

- Does it face very hot or cold conditions?

- Need ATEX or special safety certification? We handle those, too.

Unique Form Factors and Mounting Constraints

Some machines are oddly shaped. They need special mounting brackets or ways to hold the actuator. We make rodless custom actuators, trunnion mount, or inline custom actuators—whatever fits.

Application-Specific Needs and Industry Standards

- Medical devices need to be safe and super clean.

- Aerospace needs low weight and top strength.

- Food and Beverage needs easy-to-clean, non-magnetic options.

Key Design Considerations for Custom Linear Actuators

Want the perfect actuator? Here’s how you choose:

Defining Your Application’s Critical Parameters

- Force (How strong?)

- Speed (How quick?)

- Stroke (How far?)

- Duty Cycle (How often or how long it runs)

- Precision and accuracy

Environmental Factors and Material Selection

- Temperature, humidity, and contaminants

- Choose stainless steel for corrosion

- Need to keep out dust or water? Look for IP68 or IP69K sealing

Motor and Drive System Integration

Will you use a servo motor, stepper motor, or DC/AC? Want feedback from an encoder? Want a built-in controller? All these are choices you make.

Mechanical Components

Drive type changes everything. Do you want a ball screw actuator for quiet speed, or a lead screw actuator for steady lifting? Need gear driven, belt driven, or something else?

Mounting Options and Physical Constraints

Measure your space. We offer clevis mounts, flange mounts, special brackets, and smart cable management.

Real-World Applications of Custom Linear Actuators

Let’s see where custom actuators go to work:

Medical & Pharmaceutical

- Move lab fluids with precision.

- Operate surgical robots or imaging machines.

Aerospace & Defense

- Deploy satellite panels.

- Move surfaces on UAVs.

- Survive vacuum, radiation, and wild temperatures.

Industrial Automation & Robotics

- Pick-and-place robots on assembly lines.

- High-speed packaging.

- Fancy welding cells.

Scientific Research & Academia

- Fine-tune optics in labs.

- Move samples with accuracy.

Niche Industrial Sectors

- Make semiconductors.

- Package food safely.

- Keep pharma plants clean.

Table: Benefits & Applications of Custom, Non-Standard Linear Actuators

| Category | Metric/Benefit | Typical Improvement/Value Add | Real-World Example |

|---|---|---|---|

| Performance | Precision & Repeatability | Sub-micron steps | Medical imaging, lab tools |

| Force-to-Size Ratio | Up to 3x higher force | Compact robots, tight aerospace units | |

| Speed & Acceleration | Rapid or very slow movement | Packaging, dosing machines | |

| Duty Cycle | 100% operation | 24/7 factories, medical devices | |

| Environmental | Ext. Temp Range | -50°C to +150°C | Cryogenic labs, outdoor gear |

| Ingress Protection | IP68/IP69K | Marine, washdown, mining | |

| Vacuum Compatibility | UHV, no outgassing | Space simulation, particle labs | |

| Corrosion Resistance | Special alloys/coatings | Pharma, chemical plants | |

| Integration | Custom Form Factor | Unique dimensions/mounts | Drones, robotic arms |

| Integrated Electronics | Built-in sensors/controllers | Plug-and-play for robots | |

| ROI | Total Cost Ownership | 15-30% lower over 5-10 years | High-volume plants |

| Reliability | 2x standard lifespan | Life support, aerospace |

The Custom Actuator Development Process

How does custom work at Jimi?

- Consultation and Requirements Gathering: We listen to your needs. We ask about stroke, force, duty cycles, and more.

- Design, Simulation, and Prototyping: Like making a drawing before building a house, we check every step.

- Manufacturing and Quality Assurance: Using top materials and tests—just like we use for our Electric Linear Actuators.

- Testing, Validation, and Support: Every actuator is tested. Nothing leaves our factory until it’s right.

Choosing the Right Custom Actuator Partner

You want expertise. You need trust. With Jimi, you work with a team that brings:

- Years of motion control experience

- Modern manufacturing facilities

- Top-quality standards (we meet all industry standards like ATEX, ISO)

- Ongoing support after the sale

Check out our China Linear Actuator Manufacturer page for more on our factory and team.

Conclusion: Elevating Performance with Custom Linear Actuators

Not every job fits a catalog part. When you need more, custom non-standard linear actuators are the answer. Jimi Technology brings you strength, smarts, and lasting value—designed and made just for you.

Ready for a solution that works? Contact our experts today. We’ll help you build your perfect actuator, just like we’ve done for industry leaders in robotics, medical, aerospace, and beyond.

Want more details? See Electric Cylinders, check out Servo Motor Actuators or read about our Rodless Actuators.

References

- Electric Linear Actuators Product Guide

- Custom Automation Insights, Jimi Technology Co., Ltd., 2024.

- Industry Standards for Motion Control, ATEX & ISO Manuals, 2023.

- Peer-reviewed case studies: Medical Devices and Aerospace, Industry Data Reports, 2023.

Jimi Technology Co., Ltd.: Powering your ideas, one custom actuator at a time.