Do you want to make things move in tough places? Some places are hot. Some are cold. Some shake and get wet. In the world of defense, everything must work all the time. You need strong parts. You need smart designs. That is where actuators help.

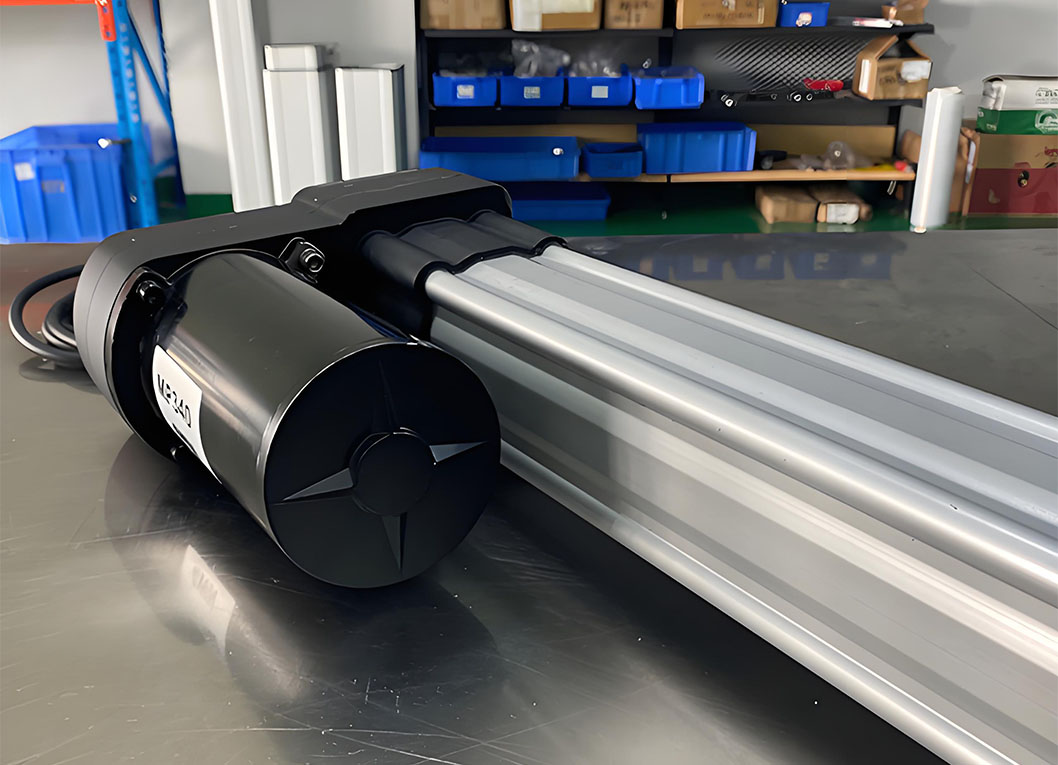

I am with Jimi (Jimi Technology Co., Ltd.). We are experts in making high-quality linear actuators, TV lifts, and automation systems. Our products make things go up, down, in, out, or turn—just by pressing a button. We help you lift, push, pull, or tilt heavy stuff, even in the hardest spots.

The Need for Strength in Defense Systems

A defense system must never stop. Actuators are a key part. They help control, guide, and protect. When you use military-grade actuators, you trust them to work in the cold, heat, dust, water, shock, and more.

Why Are Harsh Environments Tough?

Think about these places:

- Ice-cold arctic bases

- Blazing hot deserts

- Dusty, sandy tanks

- Wet and salty ships

- Sky-high planes in deep cold

- Submarines deep under water

- Rockets facing shock and noise

Do you see? Things break if not built strong. This is why defense systems need rugged actuators.

What Makes An Actuator Strong and Durable?

Actuators are much more than simple moving sticks. They are smart, solid helpers that give reliable control every time. Here is what matters:

Environmental Needs

- Extreme Temperatures: Work from freezing -55°C up to hot +125°C

- Shock and Vibration: Handle big shakes, bumpy rides, and explosions

- Dust, Water, Chemicals: Stay safe inside even if it is wet and dirty

- EMI/RFI: Block strong waves from radios, radars, or other machines

- Radiation: Survive high up, deep down, or even in space

If one part fails, the whole mission may fail.

Operational Needs

- Long Life: Must work for 100,000 moves or more

- Quick Response: Need fast, smart action for safety

- SWaP: Use small size, light weight, and low power

- Few Repairs: Hard to fix when in the field

Actuators for defense must be:

- Robust

- Reliable

- Resistant

Types of Durable Actuators

You can find many kinds of actuators. Each has good points for tough jobs.

Electromechanical Actuators (EMAs)

- Best for: Planes, drones, rockets, sensors (easy digital control)

- Good because: High precision, low repairs, uses less oil and fluid

- Watch out: Needs good cooling

Hydraulic Actuators

- Best for: Tanks, turrets, ships (needs strong push)

- Good because: High power, strong grip, quick motion

- Watch out: Beware of leaks and cold; fluids can freeze

Pneumatic Actuators

- Best for: Light arms, valves

- Good because: Easy, moves fast, light

- Watch out: Not very strong

Hybrid and Special Actuators

- Use new tech: Mix electric, fluid, piezo, or shape memory

- Perfect for: The most special needs

For all these, we make custom actuator solutions, just for you.

How We Make Actuators Strong

Let me show you what we do at Jimi:

Smart Materials and Coatings

- We use titanium alloys, stainless steel, and high-temperature plastics

- Add special coatings that fight rust and chips

Seals and Protection

- Dynamic and static seals keep dust, sand, or water out

- Get high IP ratings for top waterproof actuators

- Hermetic designs for deep sea or hot engine rooms

Robust Mechanical Design

- Big bearings and gears last longer

- Add shock absorbers to soften big hits

- Vibration isolation for smooth rides

Smart Electronics

- Shield from EMI and RFI

- Use radiation-hardened chips

- Double up on important parts for safety

Cool Under Pressure

- Add heat sinks or cooling pipes

- Let parts expand but not break in heat

Redundancy

- Use backup channels for mission safety

Meeting Defense Standards

We always follow the rules:

- Mil-Spec: MIL-STD-810G for tough weather, MIL-STD-461 for strong waves, MIL-STD-704 for plane power

- Aerospace: AS9100, RTCA DO-160

- Quality: ITAR/DFARS for export safety

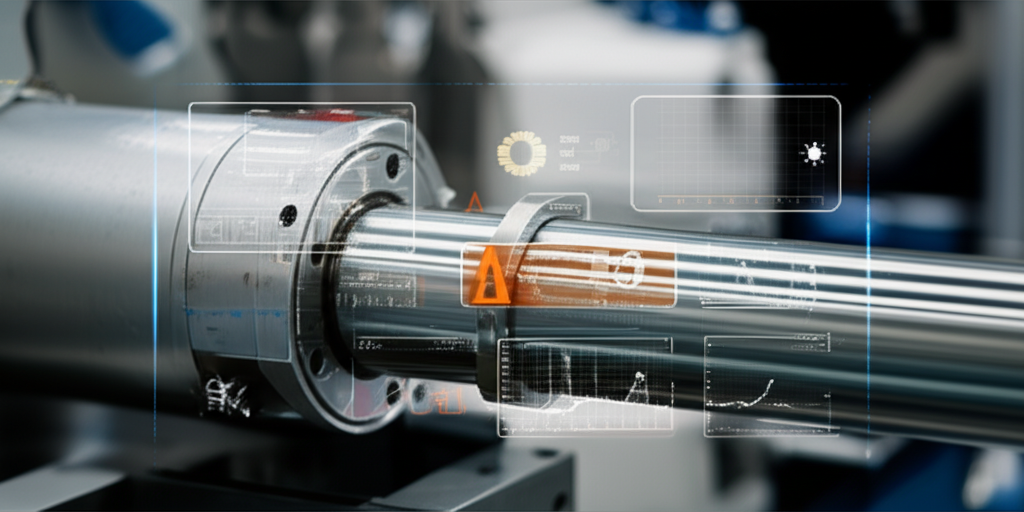

See How Strong Our Actuators Are

Here is a simple chart. You can see how tough we make our actuators.

| What We Test | How Strong | Why It’s Important |

|---|---|---|

| Temperature Range | -55°C to +125°C | Works in sun or snow |

| Shock | Up to 100G | Stands up to blows and bumps |

| Vibration | 10G RMS (20-2000 Hz) | Won't shake apart |

| Water/Dust Protection | IP67, IP68, IP69K | Survives dust storms and rain |

| Rust Resistance | 2000 hours in salt fog | Lasts on a ship or at sea |

| Life Cycles | 1 million moves | Lasts year after year |

| Precision | Less than 0.1% error | Aims, points, and positions well |

| Size & Weight | Up to 30% less in new models | Make systems faster, lighter |

Data from Jimi factory, MIL-STD-810G, and defense industry sources.

Real-Life Stories: How Actuators Win Missions

1. Keeping UAVs Up High

Old actuators in spy planes got too cold or heavy. We used strong, light EMAs and smart cooling. Now they fly in freezing skies for days. No leaks. No fuss.

2. Navy Ships That Keep Firing

Salty water and big shocks made turret actuators fail at sea. We swapped in marine stainless parts, IP68 seals, and shock absorbers. Guns always aim, even in storms.

3. Tanks That Ride Smooth

Rough trails shook suspension actuators to bits. We designed big, heavy-duty ones with triple seals and damping inside. Troops roll smoother, sensors last longer.

Want to see how heavy-duty linear actuators work in real robots? See our real customer videos.

Where Do You Use These Actuators?

Our actuators help everywhere in defense and industry:

- UAV and drone wings and tails

- Missiles and bullet guidance

- Submarine rudder and hatch doors

- Army tank roof hatches and turrets

- Ship gun turrets and valves

- Satellites and rockets

- Sensor and radar antennas

- Mobile robots and smart vehicles

Looking for servo motor actuators? Or need smart feedback on position? We have actuators with position feedback to keep you in control.

The Future of Smart, Durable Actuators

Tech keeps getting better. The new actuators are:

- Smaller and lighter—but stronger

- Smart—They talk to your systems

- Predict problems before they happen

- Use new, lighter, better materials

- Work with robots and AI to keep you safe

Why Jimi? Why Trust Our Actuators?

At Jimi, we do more than just sell. We are your solution partner. We:

- Test every actuator to the hardest standards

- Build for harsh places: defense, navy, arctic, desert

- Offer custom linear actuator manufacturing

- Help you choose the perfect actuator for your need

- Deliver robust, reliable, ready-to-deploy components with full support

Let’s Keep Your Mission Moving

If you need actuators for tough jobs, talk to Jimi. Contact our actuator experts in China. See our full line of military-grade, smart, sealed, servo, and heavy-duty actuators. From high-cycle servo linear actuators to custom automation for armored vehicles, Jimi is with you.

References:

- Jimi Technology Co., Ltd. engineering and test reports

- China Linear Actuator Manufacturer

- MIL-STD-810G, RTCA DO-160, AS9100 standards

- Servo Motor Actuators

- Industry white papers and reliability data

Want to keep your mission moving, no matter what?

Trust Jimi. We build actuators that last.