Introduction: The Crucial Role of the Load-Speed Curve in Actuator Performance

You can picture it: a machine works fine, then suddenly, it drags. Maybe the desk you swore was “height adjustable” hums slower and slower when loaded with your monitors. Or the robotic arm in your workshop just doesn’t keep up the pace when it’s lifting a heavier part. That’s not just random bad luck. Usually, it comes back to a little squiggle on a chart—the load-speed curve.

If the words “load-speed curve” sound like calculus flashbacks, don’t worry. This curve is your cheat sheet for system safety, energy savings, and long actuator life. Ignore it, and your equipment overheats, slows to a crawl, or burns out twice as fast. Master it, and you pick the right linear actuator every single time.

Let’s break it down so your projects—and your back—enjoy a little less drama.

What is a Linear Actuator's Load-Speed Curve? Deconstructing the Basics

Linear Actuator Fundamentals

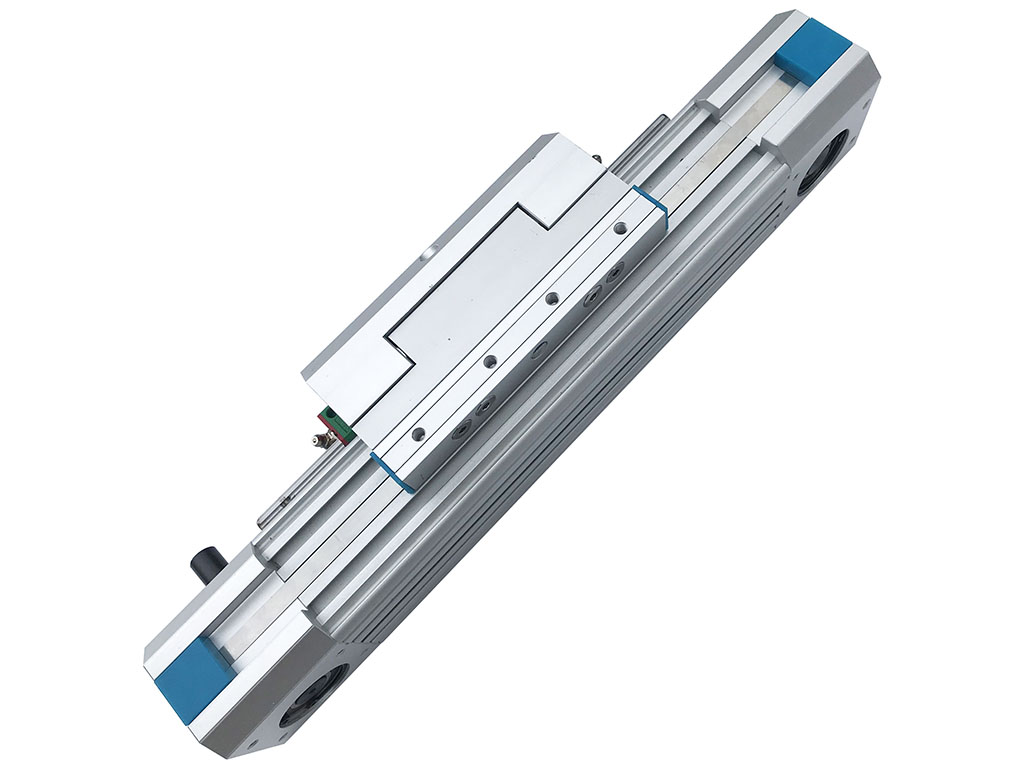

A linear actuator is an electric device that pushes, pulls, lifts, or lowers things in a straight line. It’s the hidden muscle in adjustable desks, smart homes, solar panels, hospital beds, and robots. The secret? Inside every actuator lives a motor that turns round and round. This rotary movement gets turned into straight motion, usually by a lead screw, ball screw, or a clever gearbox.

When you hit that button, you’re not just moving a desk. You’re controlling a tiny, powerful engine that teams up with mechanical magic to make things move easily—no more heavy lifting required.

Defining Load and Speed

Two friends always dance together in motion control: load and speed.

- Load (Force or Thrust): This is the object’s weight or resistance the actuator has to move. Think newton (N), pound-force (lbs), or kilograms (kg).

- Speed (Velocity): How fast the actuator makes its move, usually in millimeters or inches per second.

Here’s the catch—speed and load pull on opposite ends of the rope. The more weight the actuator pushes, the slower it goes. If there’s no load? It zips at full speed. Ask it to push its max? It slows way down to the “stall”—and that’s when the magic smoke tries to escape your motor.

Interpreting the Curve: Key Points on the Graph

Anatomy of the Load-Speed Graph

Grab any linear actuator datasheet. You’ll spot the load-speed curve—a smooth line sloping down, cutting across a graph.

- X-axis (left to right): Load or force, rising as you move right.

- Y-axis (bottom to top): Speed, fastest at the bottom left, slows as you move right.

The curve itself? It maps every possible combo of load and speed your actuator can handle. If you want both high speed and high force—sorry, you can’t have it all at once.

Critical Performance Points

- No-Load Speed (Free Speed): This is top speed when the actuator slides with zero weight (the curve’s left tip, where load is nothing).

- Stall Force (Static Load/Max Thrust): This is the heaviest object you can possibly try to move. It’s the curve’s right tip, where speed drops to zero. If you run your actuator at stall, you’re asking for a quick trip to the repair shop.

Think of no-load speed like your car going downhill with nobody inside. Stall force is like trying to start driving while hauling a trailer full of bricks. The smart bet? Stay in between for a smooth, safe ride.

Beyond the Basics: Understanding Duty Cycle and Operating Regions

The Importance of Duty Cycle

Take a kitchen blender: you wouldn’t run it non-stop blending concrete, would you? Every actuator has a “duty cycle”—how long it can work at a set load and speed before it gets tired (overheats).

- Continuous Duty: The actuator can run for long stretches at a gentler pace—lower load, moderate speed, cooler temperatures.

- Intermittent Duty: It can push harder or speed up, but just for sprints. Then it needs a rest (a cooling-off period).

Actuators don’t call for a coffee break, but they’ll stop cold or get damaged if you push them too hard for too long.

Identifying Your Operating Point

Imagine plotting your project’s needs on the graph—a point that matches your load and speed. Is it floating on the curve, somewhere close to its middle? You’re golden. Creeping toward one edge, or hovering above? Warning! You’ll run up against thermal cutouts, blown fuses, and bald spots (from tearing out your hair).

Stick with the “sweet spot”—well away from the extreme ends. This is also called the “safe operating area,” where the actuator lives a long and happy life. It’s like the cruise control on your car, not floorboarding it nor crawling at a snail’s pace.

Thermal and Current Limitations

The more you ask from your linear actuator—heavier load, faster speed—the harder the motor works. All that effort turns into heat. If temperature climbs too high (60–80°C above the room is common), your actuator faces early retirement.

What else affects the curve? Electric current. High current equals more heat, and your actuator will trip its wiring like a circuit breaker if you push past its limit.

Keep an eye on both—the real enemies of actuator life are heat and overload, not just the ticking clock.

Practical Application: Using the Curve for Actuator Sizing and Selection

Step-by-Step Actuator Sizing

Ready to size an actuator like a pro? Here’s how:

- Determine the Load: What’s the heaviest thing your actuator needs to push, pull, lift, or lower? Write down the force in newtons or pounds.

- Determine the Speed: How fast do you need that job done? Short strokes or long stretches, jot the speed you want.

- Plot Your Point: Find your load and speed on the manufacturer’s load-speed curve.

- Check the Duty Cycle: Are you in the continuous (long-run) region, or pushing into intermittent (short bursts) territory?

- Add a Safety Factor: Multiply your load by 1.25–2. If your load is 500N, you need an actuator rated at least 625N. Always plan for a bump, rattle, or surprise heavy box.

- Optimize the Choice: Stay in the curve’s “comfort zone” (usually 20–60% of stall force, 40–80% of no-load speed) for the best efficiency and life.

Factors Influencing the Curve Shape

Several things can nudge that curve around:

- Input Voltage: More voltage, up to the safe limit, means more speed—and sometimes more force.

- Ambient Temperature: Hotter room, less performance before things overheat.

- Gear Ratio and Motor Type: A higher ratio or a different type of screw (like ball screw actuators) changes the slope.

- Internal Friction: More friction, less efficiency, lower speed.

See the difference? Just like shoes come in many sizes for different jobs, actuators do too. Details matter.

The Role of Manufacturer Datasheets

When in doubt, trust the datasheet. It’s the treasure map that tells you the whole story:

- Load-speed curve? Check.

- Stroke length, mounting style, IP rating? Check.

- Extra features like feedback sensors or special safety factors? Absolutely.

Need an actuator matched for a sunny rooftop, a medical device, or a noisy factory? Start with the datasheet. You’ll spot all the details, from voltage ranges to waterproof ratings. Want some real examples? Check out our Electric Linear Actuators, Ball Screw Actuators, and Actuators with Position Feedback to see how specs shape up in the real world.

Common Pitfalls and Troubleshooting Tips

Let’s bust a few myths and dodge some landmines.

Misinterpreting Stall Force

Stall force is the biggest push an actuator can make, but you should never run here for long. Think of it as the redline on your car’s tachometer. Hit it for a split second? Fine. Camp out there? Say goodbye to your motor.

Neglecting Duty Cycle

Ignoring rest time leads to heat build-up and shortens actuator life. If your device starts smelling toasty or stops dead, you’ve probably pushed the duty cycle too far.

Underestimating Load

Don’t just guess or use the weight of your main load. Add in friction, acceleration, bumps, and anything extra that could surprise you. Over-build for safety.

Voltage Fluctuations

If your power supply sags or spikes, your actuator’s curve shifts. Lower voltage? Your actuator crawls. Higher? It might run fast but heat up—dangerously.

Conclusion: Optimizing Actuator Performance and Longevity

Choosing the right actuator is not guesswork—it’s part art, part science. The load-speed curve makes it simple: you see, with your own eyes, what an actuator can and can’t do. By understanding this curve, you dodge downtime, save energy, and build systems that run trouble-free for years.

At Jimi Technology, we don’t just sell actuators. We help you pick, size, and customize the perfect fit for jobs big or small. That’s why engineers, designers, and automation experts worldwide trust Jimi—from China Electric Cylinder Factory to leaders in Industrial Linear Actuators worldwide.

Need a hand reading that next curve? Or wondering if you can stretch your load or speed just a bit more? Our team is ready to help. Visit us for Servo Linear Actuator solutions, Electric Cylinders, and every automation answer in between.

Shape your world the smart way—read the curve, master the fit, and let Jimi help you move forward.