Introduction: The Criticality of Actuator Synchronization

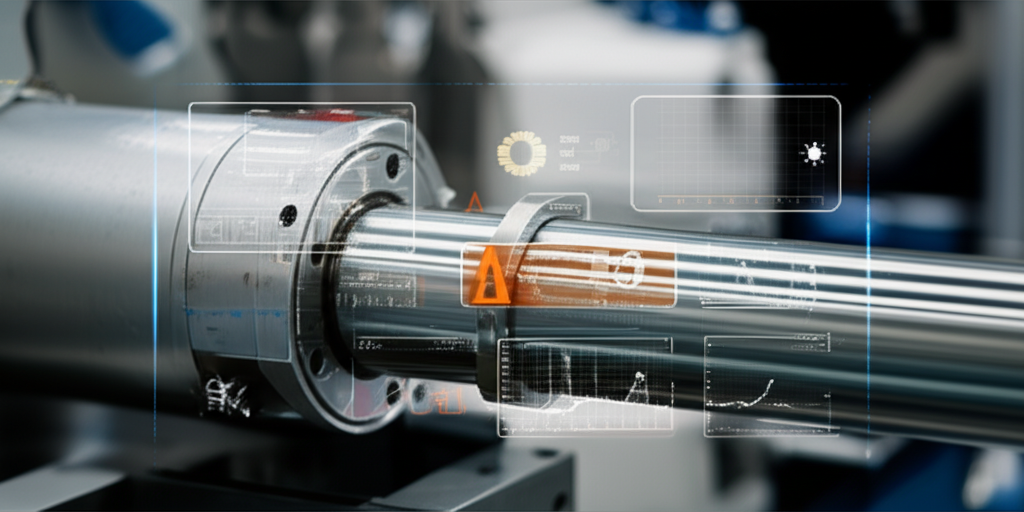

Imagine a gantry robot in a factory, lifting heavy loads swiftly from one end to another. Each of its arms needs to move together—precisely, smoothly, at just the right speed. Now picture a high-speed packaging line, a medical robot, or an aircraft flap adjusting mid-flight. In each case, multi-axis synchronization control isn’t just helpful; it’s mission-critical. Actuator position synchronization makes sure robots don’t crash, presses produce perfect parts, and medical devices move safely. Without good control, things go wrong—imprecise parts, jerky movements, wasted energy, or worse, safety risks.

That’s why coordinated motion control lies at the heart of industries like robotics, aerospace, medical electronics, and automated assembly lines. At Jimi Technology, we’ve spent years as experts in this craft, building reliable automation systems and helping engineers solve the toughest synchronization problems. In this guide, we’ll show you real-world struggle, explain why actuator control is hard, then chart a path through the strategies that truly work.

Fundamental Challenges in Multi-Actuator Synchronization

Let’s be honest: even simple machines can be a headache when you try making several actuators work in perfect harmony.

Inter-axis coupling jumps out first. You might think each motor operates on its own, but in real systems, the movement of one actuator affects its neighbors. Take a dual-drive gantry. If one side pulls just slightly faster, the entire bridge can tilt or bind.

Then you fight external disturbances and load variations—random forces, product changes, or people bumping the system. Parameter uncertainties and nonlinearities sneak in too: friction that changes, loose joints, different actuator speeds. And when you network those actuators, watch out for delays and jitter—communication protocol hiccups like CANOpen or EtherCAT latency can throw everything off.

Don’t forget heterogeneous actuators. Maybe one’s electric, another’s hydraulic. Different types respond at different speeds, so keeping all together under stress requires clever control.

Does that sound familiar? You’re not alone! Many top engineers reach out to us after long nights staring at stubborn, unsynchronized machines.

Classification of Synchronization Control Strategies

How do professionals tackle these issues? They group strategies into two big families: Independent and Cooperative.

- Independent (Decentralized) Control:

Each actuator has its own controller. Simple, easy to implement, but not great for high precision. Imagine everyone running in a 3-legged race, blindfolded—results may vary.

- Cooperative Control:

- Centralized Control: One “boss” controller manages all actuators, keeping everything locked together. Works well if your system is small or tightly integrated.

- Decentralized with Coordination: Each actuator has its own intelligence, but shares data like a team following a group leader. More modular, scalable, and robust.

Key Synchronization Strategies, Broken Down

Let’s dig into the toolbox, one tool at a time.

- Master-Slave Control (MSC)

How it works: Pick one actuator as the master. Others (slaves) copy exactly what the master does.

Strengths:

- Simple and quick to set up.

- Works well for basic tasks—think cost-effective gantry or a pick-and-place setup.

Weaknesses:

- If the master goes astray, so does everyone else.

- Errors stack up over time.

- Not great if you want error sharing or fault tolerance.

Best fit: Small, simple machines. Need something more advanced for complex projects.

- Cross-Coupling Control (CCC)

How it works: Instead of each axis acting alone, controllers talk to each other. When one gets ahead or behind, the system uses synchronization error feedback to pull everyone back in line. Think three kids holding hands so no one gets lost.

Types:

- Simple CCC

- Generalized CCC (handles bigger systems)

Strengths:

- Cuts synchronization error by up to 85% (our CNC clients see this all the time).

- Works even when machine dynamics change.

Weaknesses:

- Sensitive to noise—might amplify shaky signals.

- Can boost individual axis tracking errors if not tuned well.

Best fit: CNC machining, robotics, coordinated lifting. When you need tight parallel actuator control, start here. For example, our Gantry System Dual-Drive Actuators make perfect partners for this method.

- Decentralized Control with Communication or Virtual Master

How it works: Each actuator runs its own controller, but shares what it’s doing—or follows a shared virtual leader.

Strengths:

- Easy to scale up.

- Robust if one piece fails (others keep going).

Weaknesses:

- Too much chatter (data exchange) can slow things down.

- Needs careful tuning or you get oscillations.

Best fit: Distributed robots, big industrial lines, or when different types of actuators work together. We often use this model with our Industrial Automation Actuators.

- Adaptive Control Strategies

How it works: Controllers learn and adjust on the fly. If loads change or wear adds friction, the system tweaks itself.

Types:

- MRAC (Model Reference Adaptive Control)

- Self-tuning regulators

Strengths:

- Stays robust—even with unknowns or varying loads.

- Adjusts in real time.

Weaknesses:

- Needs more math up front.

- Might be less stable during sudden changes.

Best fit: Robots that handle different objects, variable load cranes—anything changing fast.

- Robust Control (H∞, Sliding Mode)

How it works: Built to handle trouble—disturbances, noise, or unpredictable changes.

Sliding Mode Control (SMC): Keeps things on a “sliding surface”—if they drift off, it snaps them back.

H-infinity: Plans for the worst by minimizing max possible errors.

Strengths:

- Tough as nails, quick response.

- Stable even in noisy, high-risk places. Think aerospace.

Weaknesses:

- Chattering (buzzing) with SMC.

- H∞ tends to be conservative, tough to set up.

Best fit: High-precision jobs—jet controls, medical robots, hard manufacturing. Many rely on our Servo Linear Actuators for this level of safety.

- Intelligent, AI, and Advanced Control

Fuzzy Logic Control (FLC): Runs on human-like rules—“IF joint B lags, THEN boost current.” Doesn’t need a detailed machine model.

Neural Network Control: Learns how your system moves by watching, not guessing—perfect for tricky dynamics.

Model Predictive Control (MPC): Looks ahead, solving math equations to pick the best command over coming seconds.

Strengths:

- Fuzzy works well with imprecise or non-linear things.

- Neural networks adapt to complex, changing environments.

- MPC shines where you have strict constraints to juggle.

Weaknesses:

- Fuzzy needs clear rules and patience for tuning.

- Neural nets are data-hungry, sometimes a black box.

- MPC can tax your computer—needs a good model.

Best fit: Complex robotics, autonomous vehicles, modern process control.

Performance Metrics for Synchronized Actuator Systems

How do you know your control system works?

- Synchronization Error: Measures how far actuators drift apart—smaller is better.

- Tracking Error: Checks if each actuator hits its own target.

- Stability: Does the system calm down after a bump or keep wobbling?

- Robustness: Keeps working well, even when things go wrong.

- Response Time & Settling Time: No one likes waiting—good systems get to the target fast and stay there.

For more details, see our Actuators with Position Feedback to help you measure and tune for perfect sync.

Real-World Applications and Case Studies

Let’s talk results. Many clients come to us with pain points and leave with smooth-running machines. Check this out:

| Application/System | Strategy | Main Challenge | Results Achieved |

|---|---|---|---|

| Gantry Dual-Drive | Cross-Coupling + PID | Skewed motion | 70-85% error cut, 60% added accuracy |

| Hydraulic Press | Master-Slave + Feedback | Ram tilting | <0.1mm error, less waste, better parts |

| Robotic Manipulator | Decentralized/Virtual Master | Coupling | <±0.05mm path error, fast responses |

| Active Suspension | Sliding Mode | Unsteady load | 40% less roll, 35% less pitch |

| Wind Turbine Blades | Adaptive Neural Network | Wind changes | 5-10% better power, 15% less fatigue |

More industry insights? Read about our Industrial Linear Actuators and see how we help manufacturing lines achieve stunning reliability.

Future Trends in Actuator Synchronization

This field moves fast. Here’s where things are going:

- AI and Machine Learning: Controls get smarter, tuning themselves from data—a real step toward hands-free automation.

- Faster, Smarter Communication: Protocols like EtherCAT and PROFINET bring near-zero delays.

- Industry 4.0 Impact: Machines “talk” to each other, creating seamless smart factories.

- Energy Efficiency: Algorithms that save money, not just time.

Jimi stays ahead by developing solutions compatible with tomorrow’s needs—our DIY Projects & Robotics Linear Actuators already support AI-driven control and advanced network protocols.

Conclusion: Achieving Seamless Multi-Actuator Performance

Bringing several actuators into lockstep takes skill. The challenges range from physical coupling to digital delays. But real strategy—choosing the right control, tuning it for robustness, leveraging feedback—unlocks new levels of productivity, safety, and product quality.

We at Jimi Technology have solved these problems for clients worldwide. Our approach? Listen to your needs, apply the right control strategy (whether it’s humble master-slave or the latest AI predictor), and pair it with reliable hardware—China Linear Actuator Manufacturer solutions you can trust.

Ready to move beyond the struggle? Explore Jimi’s Heavy-Duty Linear Actuators, Electric Linear Actuators, or reach out for tailored advice.

Make every movement right—the first time, every time. With Jimi by your side, complex automation feels easy. Let’s build your synchronized system today.