Precision Motion: Optimizing Fruit & Vegetable Processing with Advanced Linear Guides

You know the routine. The plant buzzes to life. Conveyor belts start to hum. Boxes of apples, crates of carrots, towers of tomatoes—each needing to be moved, sorted, weighed, sliced, and packed faster than ever. You push to boost yield. Sanitary checks hang over your head. Every part must be clean, precise, reliable. But do your machines keep up, or do they hold you back?

Let’s be honest: old motion systems jam, bend, or get all gummed up with every washdown. Tiny bits get stuck in crevices, threatening food safety. Operators waste hours fixing alignment. Downtime burns profit. Fatigue sets in when team members must push or adjust machines all day. It’s not just about speed. It’s about accuracy, hygiene, and repeating results—every shift, every day.

As pressure for higher quality and safer food grows, manual fixes just don’t cut it. Customers demand spotless produce. You need razor-sharp portioning, gentle handling, fewer recalls, and zero contamination. The big question: How can you hit these goals without making your machinery harder to clean, operate, or trust?

That’s where linear guides step in and change the game.

Why Linear Guides Are Must-Have Solutions in Fruit & Vegetable Processing

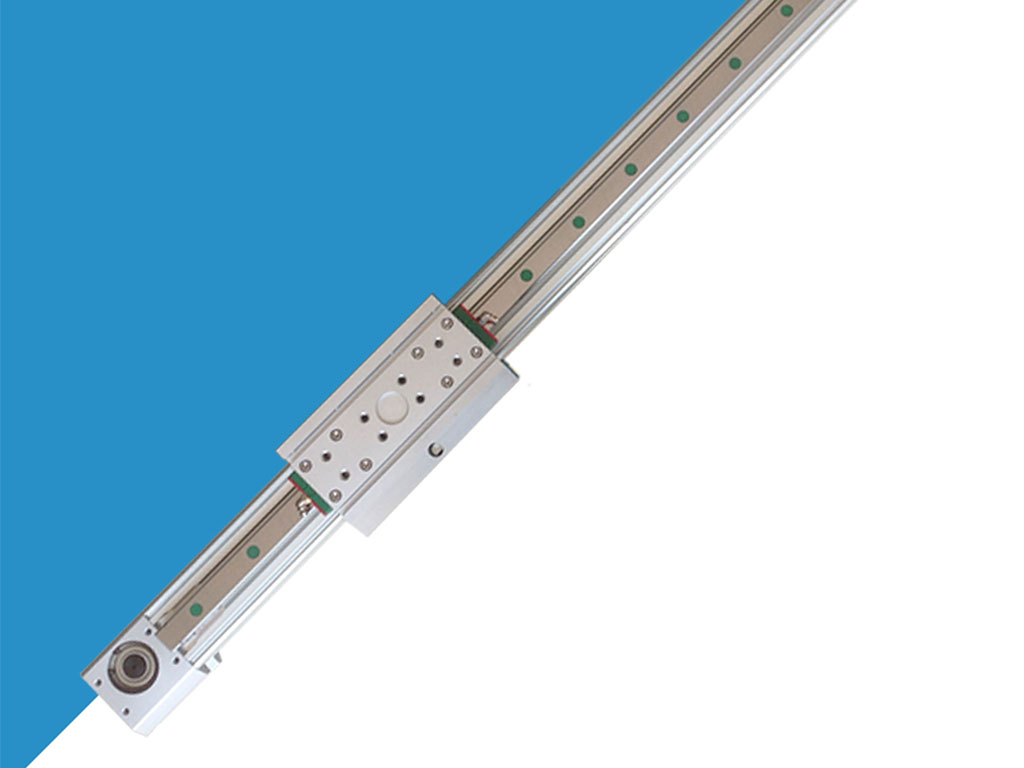

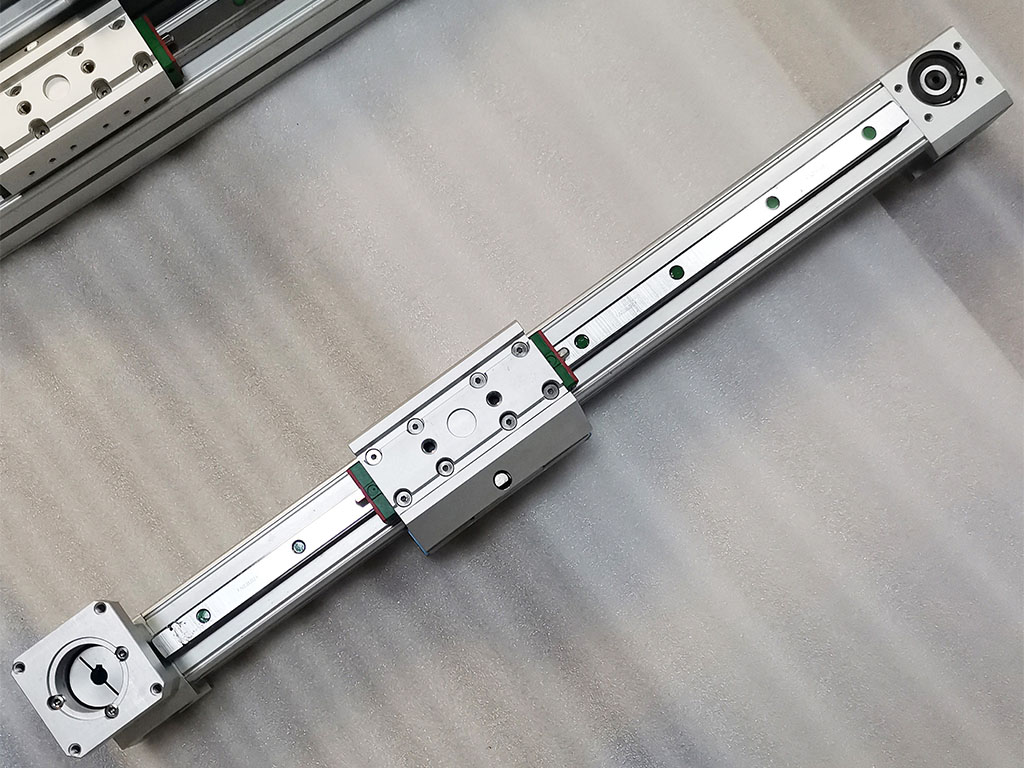

Linear motion systems are the secret engine behind modern food plants. We use them daily at Jimi. They slide, lift, or nudge everything from berries to beets—quietly, smoothly, again and again.

So, why do smart plants use hygienic linear guides instead of old-school bearings or rails?

- Unmatched Precision & Repeatability: Picture an optical sorting system. Every apple must glide under a camera, get scanned, and be sorted at lightning speed. Only precision engineering keeps the fruit lined up, every single time.

- Accelerated Throughput & Efficiency: Linear guides help machines move faster, slashing bottlenecks. With advanced guides and smooth rails, a sorter can run up to 40% faster than one using manual adjustment or basic wheels.

- Superior Hygiene & Sanitation Compliance: Every component faces repeated hot water blasts, foaming chemicals, and strict rules like FDA, USDA and EHEDG standards. Jimi’s linear guides feature sealed blocks, smooth stainless, and wipe-clean surfaces. They leave no place for germs to hide.

- Exceptional Durability: In produce plants, water, grit, and acids wreck standard hardware. Our stainless steel linear components resist corrosion and abrasion, standing up to even the harshest washdown conditions.

- Reduced Maintenance: Fewer sticky jams. Less time fiddling with clogged bearings. We’ve seen up to a 30% drop in unplanned maintenance after upgrading to these guides. Downtime shrinks. Uptime soars.

- Versatility: Need to upgrade a carrot dicer? Install new packaging equipment linear motion? Linear guides fit almost anywhere. They adapt to every step, from high-speed packaging to cold-storage transfer lines.

Where Linear Guides Make a Difference

It’s not just sales talk. Let’s see where these motion heroes go to work for you:

- High-Precision Sorting and Grading

- Optical Sorting: Imagine cameras scanning apples zipping down the line. With linear guides, each fruit lands in the sweet spot for perfect vision, reducing sorting mistakes and boosting throughput by up to 35%.

- Weight Sorting: Scales move with pinpoint accuracy, thanks to low-friction rails. More consistency. More trust in every portion.

- Automated Cutting, Slicing, and Dicing

- Uniform French fries, evenly sliced tomatoes, perfect salad cubes—these are no accident. Linear guides keep blades steady and at the right height. Blade changes? A snap. The result: up to 10% less trim waste, so you don’t throw profits in the bin.

- Efficient Packaging & Palletizing Lines

- Robotic Pick & Place: Soft fruit needs gentleness and speed. Linear-guided arms pick up, move, and place produce into packages or trays—fast, but never rough. The results: cleaner packs, less damage, more sellable product.

- Tray Loading: Bags or clamshell containers land where they should, every time. Uniform packs, happy retailers.

- Washing, Peeling, and Inspection

- No one wants sandy spinach or bruised berries. Guides steer sprayers side to side, position brushes, and keep automated cameras stable. No skip, no wobble, just clean, inspected veg all day.

- Material Handling and Transfer

- Conveyor transitions. Route changes. Quick stops. With guides, produce glides from station to station. No more bottlenecks. Less wasted motion.

Choosing Linear Guides for Food Processing: What to Look For

You know what a bad component feels like—it’s sticky, hard to clean, and rusts if you glance at it the wrong way. So, what should you demand in your next system? Let’s break it down.

A. The Right Materials

- Stainless Steel (304, 316L): The industry gold standard. Resists corrosion, stands up to bleach or brine, and laughs off high-heat sterilization. It’s why our Stainless Steel Actuators are trusted in harsh lines.

- Food-Grade Polymers: For light loads or lower-cost needs. Lightweight, resist chemicals. Some even run dry, no lube needed, fighting contamination.

- Ceramic Bearings: Extreme cases call for ceramics—think acids, ultra-cold, or when you need non-magnetic rails.

B. Enduring the Environment

- IP69K Washdown Rated: Go for sealed carriages. IP69K guides keep water and chemicals out. You can blast away filth—these guides won’t blink.

- Chemical and Temperature Resistance: Fruit and veg lines go from freezing chill to hot steam. The best guides shrug it off.

C. Designed for Sanitation

- No Hidden Spots: Crevices let bacteria hide. Look for guides with rounded edges, minimal seams, and closed ends. Our guides trim away those danger zones.

- Lubrication-Free/Sealed Bearings: Oils and food don’t mix. We recommend guides that need no extra grease or come pre-sealed.

D. Performance Matters

- Load Capacity: Heavy watermelons? Light berries? Match your guide to your weight and force needs, using our Linear Guides & Rails calculator.

- Speed & Accuracy: High-speed lines need high-precision rails—ours achieve positional accuracy down to +/- 0.005mm. Talk about peace of mind.

E. Certification Is Non-Negotiable

- FDA, USDA, 3-A, EHEDG: Only use guides that are proven to meet or beat these hygiene and safety standards.

Real Results: The Proof Is in the Produce

Case Study 1: Berries at Warp Speed

- A berry packer came to us, frustrated. Sorters jammed, cleanings dragged on, downtime soared. Our hygienic linear guides went in. The result? 40% more throughput. Teams stopped chasing jams. Quality soared. Compliance audits went from stressful to simple.

Case Study 2: Vegetable Waste Slashed

- Another client processed diced carrots and peppers. Too much trim landed in the waste bin. After a Jimi linear guide upgrade, waste dropped by 10%. More saleable product, less trash, less cost.

Expert Eye: What’s Next?

- Smart plants now link guides with sensors—Industry 4.0 in action. Monitor wear, plan service, predict problems before they start. Welcome to the era of predictive maintenance.

Tough Challenges? Smart Solutions

Food plants fight harsh cleaners, water, bugs, and tight margins. Here’s how you win anyway:

- Chemicals destroy parts: We use the best stainless, top-grade polymers, and smart coatings.

- Microbial harborage: We follow EHEDG and 3-A principles. No flat edges or open-seam rails. Fast water runs right off.

- Upfront cost worry: True, advanced guides cost more. But see the long game—a 2-4 year ROI thanks to lower waste, less downtime, and smaller repair bills. Check our cost-effective linear motion for food to see the math for yourself.

Jimi Technology: Your Expert in Linear Motion

Here at Jimi Technology, we don’t just sell linear guides. We engineer motion control systems for food machinery. Our team helps you select the right rail, build it custom if you need, and back it with industry-best advice.

Want to run faster lines? Crush food safety audits? Boost yield? We’re the team the world’s best plants trust. Explore our expert-built Electric Linear Actuators, Industrial Automation Actuators, and Rodless Actuators. Need to move up to high-speed? Check out our High-Speed Linear Actuators.

The Road Ahead: Cleaner, Safer, Smarter Lines

Fruit and vegetable plants can’t stay stuck in the past. The best in the business use advanced linear guides to drive up speed, boost accuracy, reduce downtime, and cut costs. The numbers speak for themselves:

| Benefit | Typical Improvement |

|---|---|

| Throughput | 25 – 40% |

| Product Waste Reduction | 5 – 15% |

| Less Unplanned Downtime | 20 – 30% |

| Direct Labor Cost Reduction | 15 – 20% |

| ROI Payback Period | 2 – 4 years |

Don’t let your plant stall with old rails or bearings. Give your fruit and veggie lines the boost they need. Partner with Jimi Technology—your trusted guide to streamlined, safe, and smart automation.

Ready to turn guesswork into precision? Let’s build a better food plant—starting today.