Unlocking Diagnostic Excellence: The Critical Role of Precision Linear Guides in CT & MRI Scanners

Imagine you wake up feeling unwell. Your doctor orders a CT or MRI scan to find out what's wrong. You trust the machine will show everything clearly. But what if a blurry image or tiny error in movement hides the real problem? That's the hidden danger nobody wants.

Every day, CT (Computed Tomography) and MRI (Magnetic Resonance Imaging) scanners help doctors find tumors, measure fractures, and plan surgeries. When these machines work right, they can save lives. But clear images and accurate results depend on something you rarely see: precision linear guides. These parts may sound small, yet they make a huge difference to your scan and, sometimes, your future.

Let’s walk through why accuracy matters so much in medical imaging. Then you’ll see what can go wrong without precision. Finally, you’ll discover how expert solutions from Jimi Technology bring peace of mind to patients, doctors, and device makers worldwide.

Demanding More from Medical Imaging

First, why do hospitals and clinics invest in the best machines? Simple. They want images that are crisp, clear, and true. When a radiologist reviews your scan, they don’t want to guess. They want to know for sure.

A top-quality scan gives more than just pictures. Doctors can spot even the smallest tumor or injury, guide a needle for a biopsy, and measure changes over time. One missed detail can send treatment down the wrong path.

But how do these scanners get such detailed images? They need every moving part to work just right. The patient table must glide smoothly. The gantry—the big circle that spins around you—must move without shaking. Every tiny motion must happen again and again, always the same.

The Problem: Inaccuracy Can Cost More Than You Think

Now let’s picture what happens when things aren’t perfect. Maybe the table jerks just a little. Or maybe the gantry wobbles because a guide is loose. To you, that might feel like a minor bump or shake. To the machine, it’s a disaster.

A small jerk can make the image blurry. The doctor can’t tell if a shadow is a tumor or just noise. Sometimes you need to lie still again for a second scan—more time, more anxiety, more radiation for CT. For kids or elderly patients, lying still even once is hard enough.

Worse, small errors can create “artifacts”—strange patterns that hide or mimic disease. False alarms lead to worry and costly follow-up tests. Missed findings delay the right treatment.

Sometimes, old or basic linear guides are the culprit. Over time, friction wears them out. Vibration creeps in. Dust or fluids can gunk things up if the system isn’t built for hospital-grade cleanliness. Hospitals see growing expenses for repairs and maintenance, more re-scans, and lower patient satisfaction.

If you build, buy, or maintain these machines, you know how a small part can create a big headache.

The Solution: Precision Linear Guides—The Unsung Heroes

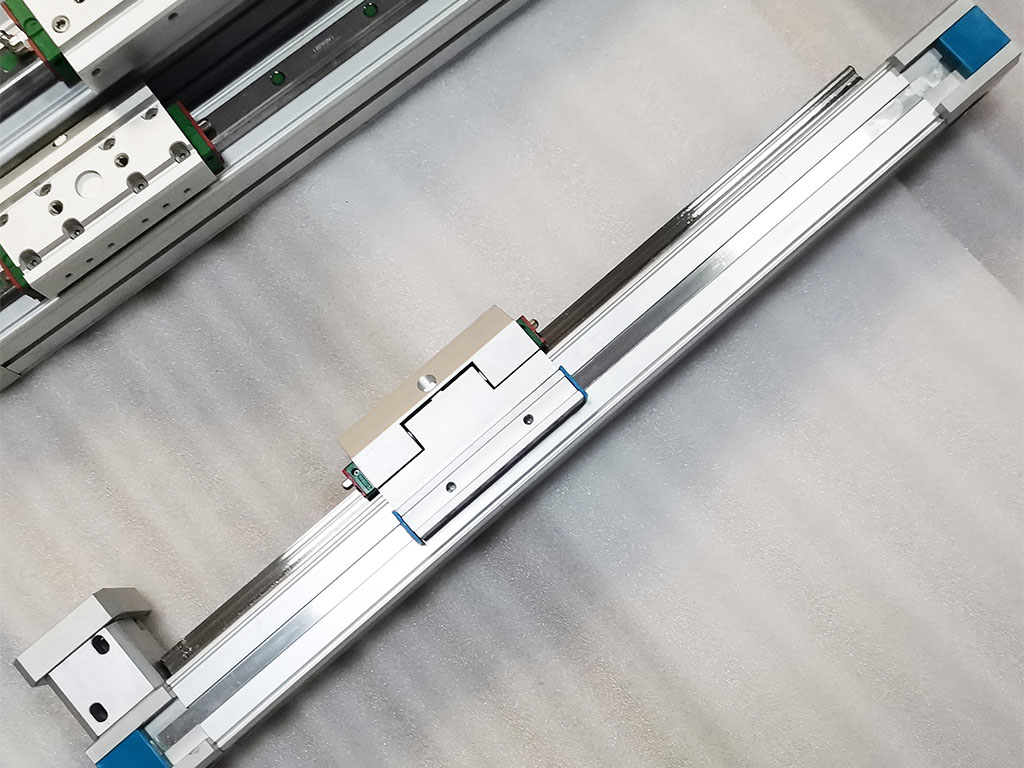

So what’s the answer? Precision linear guides. These are advanced rails, bearings, and stages that let parts move with micrometer-level accuracy, almost no friction, and no play. Everything glides as it should. No shakes, no squeaks, no guessing.

In modern CT scanners, these guides help the gantry spin fast and the table move in a straight line—quickly, quietly, and always right on target. They’re built to handle heavy loads and constant use without breaking down. Their stiffness keeps everything steady, so your scan shows only what’s real.

In MRI scanners, linear guides face a new challenge: the huge magnetic field. Standard steel parts can’t go near these magnets. That’s why MRI-grade linear guides use non-magnetic materials like ceramics or special polymers. They avoid magnetic interference and keep electrical noise away from the sensitive imaging coils.

By cutting down vibration and running almost silently, these guides help doctors get a better signal-to-noise ratio (SNR). That’s a fancy way to say: the real image stands out, not silly background fuzz. For patients, a quieter, faster scan means less fear and stress. You stay still, and the doctor gets a perfect picture.

The Direct Benefits: Numbers Tell the Story

Don’t just take our word for it. Studies show what hospitals see after switching to high-end linear guides:

| Impact Area | Improvement Description | Quantifiable Result |

|---|---|---|

| Image Quality | Fewer motion artifacts (blurring, streaks) | Up to 25–40% reduction |

| Diagnostic Accuracy | Finds more subtle abnormalities | 5–10% better detection |

| Patient Safety (CT) | Lower radiation (fewer re-scans) | Up to 15% less radiation |

| Patient Comfort | Scans finish faster, less time stressed | 5–15% faster scans |

| Machine Uptime | Longer time between repairs | 2–3 times longer life |

| Operational Efficiency | Fewer repeat scans needed | 10–20% fewer repeats |

| SNR Improvement (MRI) | Clearer images, less noise | 5–7% better SNR |

| Acoustic Noise (MRI) | Less noise during table moves | 3–5 dB quieter |

These numbers have real meaning. Cleaner images mean more confidence for everyone. Faster, quieter scans turn dread into relief. And greater uptime puts more patients through the scanner every day.

What Makes A Guide “Medical-Grade”?

Now you might wonder: aren’t all linear guides the same? Not even close. Here’s what sets precision guides apart for CT and MRI work:

- High Accuracy & Repeatability: Every move lands in exactly the same spot, every time. No back-and-forth, no drift.

- Stiffness & Load Capacity: Built solid to hold heavy gantries and patient tables without bending or shaking.

- Ultra-Smooth Motion: Low-friction surfaces ensure no grinding, no catching—just a glide.

- Cleanroom & Corrosion Resistance: Stands up to hospital cleaning chemicals, bodily fluids, and strict hygiene rules.

- Non-Magnetic Materials (for MRI): Ceramics, plastics, and special metals keep the magnetic field pure.

- Silent Operation: No rattling parts, no extra noise to scare or distract the patient.

- Reliability & Long Life: Works day in, day out, needing little to no maintenance.

At Jimi Technology, we engineer our linear guides and rails to meet and exceed global standards like ISO 13485 and FDA requirements. We know healthcare can’t settle for “good enough.” Your patients and staff deserve the best, every single time.

Jimi Technology: Trusted Experts in Smart Medical Motion

Experience matters. At Jimi Technology, we’ve supplied high-precision motion systems to hospitals, clinics, and leading medical device manufacturers around the world.

We don’t just sell parts. We solve problems—from custom electric cylinders for heavy loads to quiet, ultra-clean guides for the next generation of pediatric MRI systems. Our team works closely with OEMs and medical engineers to design, test, and refine each product until it meets the highest expectations. Need something special? We deliver customized guides for unique designs, always focusing on your needs.

Here’s a quick look at how our work makes a difference:

- Faster Diagnosis in Oncology: When a hospital upgraded old guides to our profiled rail technology, they saw a 17% drop in inconclusive scans and an 8% boost in patient throughput.

- Quieter Scans for Kids: A maker of pediatric MRI systems used our non-magnetic, ceramic linear guides and cut acoustic noise by 5 dB—leading to a 30% reduction in sedation for anxious children. That’s less risk and a far better experience.

With our expertise, you get more than just top-shelf hardware. You get a partner who guides you from idea to end result.

The Future: Even Smarter, Smaller, More Reliable

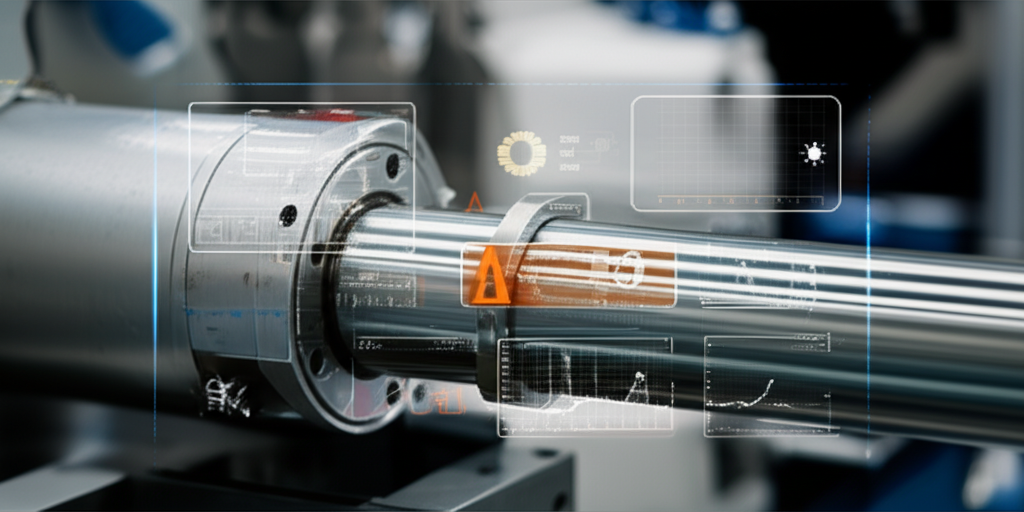

Every year brings new breakthroughs in medical imaging. Scanners are getting smaller, faster, smarter. Precision linear guides are keeping up—thanks to smarter materials, better sensors, and AI-powered monitoring.

Picture this: IoT sensors inside the motion system warn you before something fails. New composite materials cut down on weight and noise, making the system nearly silent and lightning-fast. Hospitals enjoy more uptime, less waste, and greener, more energy-efficient machines.

Jimi Technology is at the forefront of these changes. We invest in R&D, work with leading labs, and help set the bar for quality and innovation.

Choosing the Right Partner: What Really Matters

If you’re in charge of designing, sourcing, or maintaining medical imaging systems, don’t cut corners. Look for a provider who checks every box:

- Proven Technical Expertise: Deep knowledge of medical motion control and engineering.

- Certifications and Regulatory Rigor: Compliance with ISO 13485, FDA, CE, and more.

- Tailored Solutions: Ability to customize linear guides for your exact system.

- Reliable Support: Fast response, global logistics, and supply chain dependability.

- Industry Trust: Strong track record partnering with world-leading healthcare brands.

With Jimi Technology as your guide, your system gets the precision, quality, and support it deserves. Need complementary parts? Our China Linear Actuator Manufacturer page gives you endless options—from standard inline actuators to servo motor actuators and more.

The Bottom Line: Precision that Powers Care

Step into any modern imaging suite—CT, MRI, or X-ray. Underneath the high-tech controls and displays, you’ll find the quiet, powerful heart of precision linear guides at work. They aren’t just parts. They enable clear answers, calm patients, and confident doctors.

At Jimi Technology, we believe every move counts—because every image matters and every life matters. Ready to raise your system to the next level? Get in touch. Let’s build a future where diagnostic excellence is standard, not surprise.

Discover more, ask questions, or find the perfect fit for your needs at Linear Guides & Rails or check our Electric Linear Actuators collection for complete motion solutions. Choose precision that never lets you—or your patients—down.