Introduction: The Secret Behind Smooth Moves

Think about the last time you struggled to open a stiff drawer or adjust a heavy screen. Maybe you watched a robot arm move with perfect accuracy in an assembly line or got a precise scan in a hospital. All these moments share a quiet hero—linear motion systems.

Linear motion systems may sound technical, but you see them everywhere. You find them in factories, hospitals, and even your own home. They give objects smooth, straight-line movement—no more struggling or brute strength needed. But how do these systems really work, and why do you need to know about them?

Let’s explore, step by step.

I. What Are Linear Motion Systems & Why Do They Matter?

Linear motion systems are setups that move things in a straight line. That’s it—no spinning, no twisting, just push-pull or up-down. But this simple idea powers the most advanced machines on earth.

Picture a hospital bed rising with a button press or a solar panel aiming at the sun. That’s a linear actuator at work—a core part of any linear motion system. These systems convert an energy signal (like electricity) into straight movement.

Why do they matter?

- Precision: Move parts exactly where you want them—over and over, without fail.

- Speed: Automation speeds up work in factories or labs.

- Safety: Keep people safe by letting machines handle heavy or dangerous tasks.

Today, linear motion systems drive the world’s progress—from robots on a factory floor to life-saving devices in healthcare.

II. The Core Principles of Linear Motion

Let’s break it down to basics—what makes a linear motion system “tick”?

A. What Is Linear Motion?

It’s just straight movement. Imagine sliding a book across a table. That book’s trip is “linear motion.” No circles, no arcs, just straight-line travel.

B. The Four Key Ideas

- Force: How much push or pull does it need?

- Speed: How fast does it go?

- Acceleration: How quickly does it speed up or slow down?

- Accuracy: Can it hit the same spot every time?

C. Linear vs. Rotary: The Big Difference

Linear motion is a straight shot. Rotary motion spins things like wheels or gears. Need to move straight (like a drawer)? You want linear. Need to spin (like a fan)? Go rotary.

III. What Makes Up a Linear Motion System?

It takes teamwork. Each part plays a vital role.

A. Linear Actuators

These are the engines of straight-line moves.

- Electric Actuators: Most common. Powered by electricity. Use ball screws, lead screws, or even magnets with a linear motor.

[Check out our full lineup of Electric Linear Actuators.]

- Pneumatic Actuators: Use air. Fast and good for light loads.

- Hydraulic Actuators: Use oil. Super strong for heavy work.

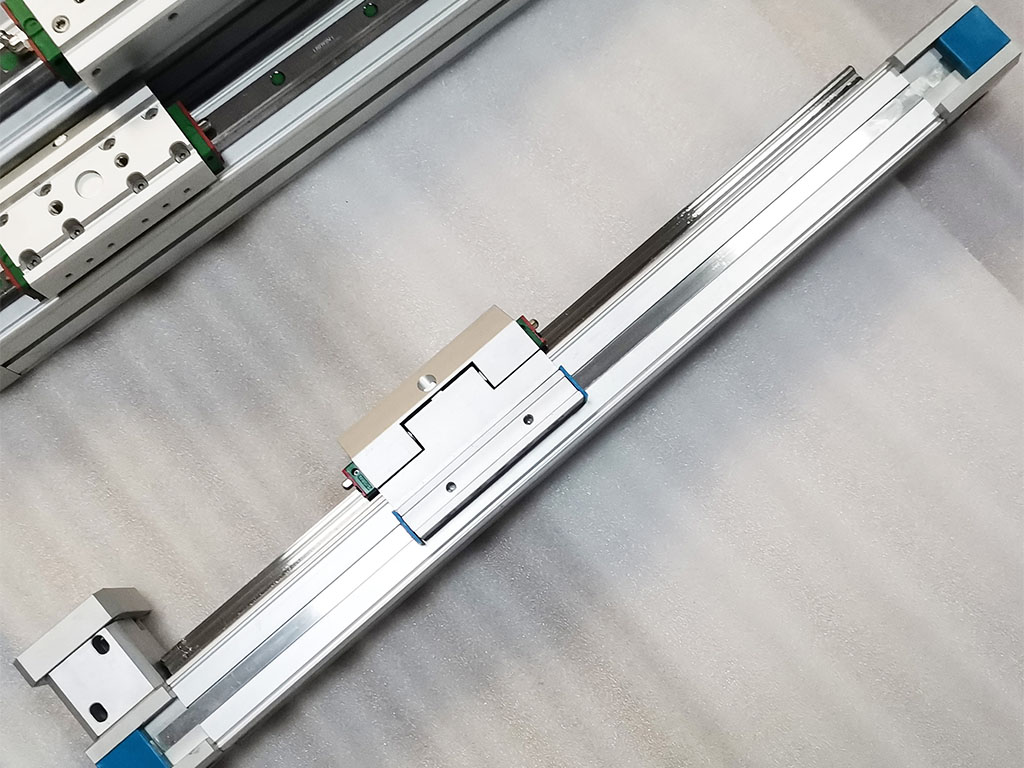

B. Guides and Bearings

Actuators push, but guides and bearings keep the movement smooth:

- Profiled Rail Guides: Think of these like railroad tracks for your components (brands like HIWIN, THK shine here).

- Ball Bushings: Hundreds of tiny balls roll to reduce friction, just like ball bearings in a skateboard (Thomson is a key name).

- Dovetail Slides: Solid, for jobs that need extra stability.

- Plain Bearings: Simple, low-cost ways to cushion movement.

Explore our Linear Guides & Rails to learn more.

C. Motors for Linear Motion

- Stepper Motors: Move in small steps. Great for repeatable positions.

- Servo Motors: Even more precise. Add feedback for total control.

- Direct-Drive Linear Motors: No screws, just magnets—a new high-speed option for robotics.

If you want cutting-edge motion, browse our Servo Motor Actuators.

D. Controllers and Feedback

- Controllers: The brains. Tell your actuator when and how to move.

- Sensors & Encoders: Eyes and ears—help the system know its exact position.

Want plug-and-play ease? Our Actuator Controllers make setup easy.

IV. How Do Linear Motion Systems Work?

Here’s a simple analogy. Imagine you’re sliding a mug across a smooth table. Your hand (actuator) pushes the mug. The table’s surface (guide) makes sure the mug slides straight. If your friend tells you when to stop, that’s feedback!

Open-loop Control: You guess where to stop, but you might overshoot.

Closed-loop Control: You use feedback and always hit the mark.

In real-world systems, closed-loop wins for tricky jobs—think medical robots.

Two Big Goals:

- Repeatability: Hit the same target every time.

- Accuracy: Hit the true target—even if it’s a tiny spot.

V. Types and Configurations: Picking the Right System

A. By Actuator

- Electric: Versatile, clean, quiet.

- Pneumatic: Fast, simple, inexpensive for light tasks.

- Hydraulic: Muscle for heavy loads.

B. By Layout

- Single-Axis: Moves on one line (X or Y).

- Multi-Axis: Moves in two or more (X, Y, Z). Gantry robots and Cartesian robots fall here. They build everything from cars to circuit boards.

C. Integrated vs. Component

Some systems come “ready to install.” Others let you mix and match.

Explore our Industrial Automation Actuators for off-the-shelf solutions.

VI. Where Do Linear Motion Systems Shine?

They shine in places you might not expect.

A. Industrial Automation

- Assembly Lines: Pick and place parts with robot arms.

- Material Handling: Move boxes, stack goods, sort items.

- Packaging: Bagging, sealing, and boxing—it all gets easier.

B. High-Precision Industries

- Semiconductors: Move wafers with micron accuracy.

- Medical Devices: Power hospital beds, lab robots, and diagnostic machines.

- 3D Printing: Control printheads and platforms.

C. Other Essential Uses

- CNC Machines: Carve, cut, or print—precision every time.

- Robotics: Robots depend on straight-line motion for arms and conveyors.

- Inspection/Testing: Move samples or sensors for non-stop checks.

Want to automate tricky tasks? Our DIY Projects & Robotics Linear Actuators are perfect for innovators.

VII. How Do You Pick the Best Linear Motion System?

Don’t just choose the first option that pops up. Here’s what to look for:

- Performance

- Load Capacity: Will it lift your load?

- Speed/Accuracy: Do you need racing speed or watchmaker accuracy?

- Duty Cycle: Will it run all day, or just sometimes?

- Environment

- Cleanroom? (For labs or food)

- Wet, dusty, hot, or cold?

- Vacuum or severe conditions?

When you need durable or waterproof, visit our Waterproof Linear Actuators.

- Upkeep

- Maintenance: Do you want “set and forget,” or will you clean it often?

- Reliability: Less downtime equals more productivity.

- Cost & Value

- Balance up-front price with savings over time. Efficient systems often pay for themselves fast.

VIII. What’s Next for Linear Motion? Tomorrow’s Trends

Miniaturization: Big power now fits in tiny packages, opening new doors in medicine, consumer goods, and research.

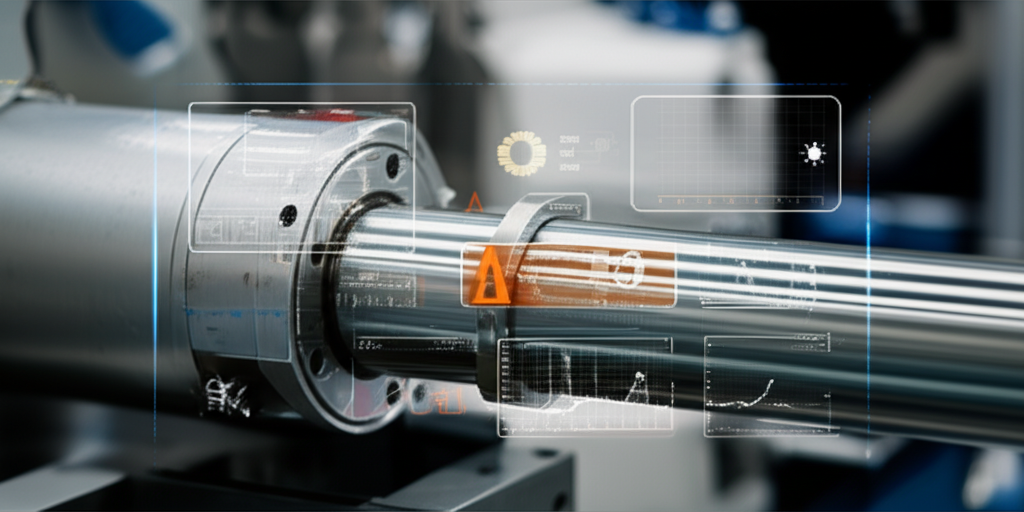

Smart Systems: The Internet of Things (IoT) makes actuators “talk” with sensors and controllers. Predictive maintenance means you fix problems before they stop your line. Our industry now pushes towards “smart factories.”

Energy Efficiency: Electric linear actuators use less power. In a real case, switching from air-powered to electric saved a Bosch Rexroth factory 30% on energy and made cycles 15% faster.

Precision and Reliability: Sealed linear bearings, like those from Igus and NSK, cut downtime 25% more than open systems in a 3-year test.

Market Growth: The linear motion market will hit $13.5 billion by 2028. Why? Factories, robots, and precision industries all need solutions only linear motion systems offer (Grand View Research).

Ready to be part of the future? Jimi Technology leads these innovations.

IX. Why Trust Jimi Technology for Linear Motion Solutions?

We’re not just sellers. We at Jimi live and breathe linear motion. With decades designing, building, and supporting systems, we know the headaches you face—missed targets, wasted time, rising costs.

That’s why quality, reliability, and service drive everything we do:

- Expert Team: We walk you through selection, design, and troubleshooting—no jargon, just solutions.

- Top Products: From rugged industrial to whisper-quiet medical, we build to last. Our linear actuators, guides, and motors lead the field.

- Complete Support: Controllers, feedback, remote kits—we’ve got every piece. If you need a custom touch, we make it happen.

Don’t let frustration stall your next big project. Turn wasted effort into smooth, smart moves.

Get Started Today—Move with Confidence

Ready to stop wrestling with old problems? Whether you want more speed on your assembly line, precision in your lab, or comfort at home, linear motion systems open new doors.

Check out our in-depth guides on Electric Linear Actuators, Linear Guides & Rails, and our DIY Projects & Robotics Linear Actuators.

And if you need help, reach out—Jimi is here to power your ideas, simplify your work, and move your world forward. The future moves in a straight line. Let’s build it together.