Imagine this: a single, tiny piece out of place inside a battery can lead to wasted time, high costs, or even a safety hazard. In the fast-growing electric vehicle (EV) and energy storage industry, every micron matters. When you think about how complex lithium battery manufacturing is, it’s clear why companies are racing to make each step as accurate as a perfect clock.

The Indispensable Role of Precision in Lithium Battery Manufacturing

Battery safety and long life depend on details you can barely see. Making lithium-ion batteries is a dance where every move must be on beat. You have to keep layers stacked straight, liquids measured just right, and parts joined tight. One slip—one edge off by a hair—and the battery won't work like it should. In the worst cases, it can even catch fire.

Let’s break it down:

- Electrode Manufacturing: This is where thin sheets of material get coated and sliced. It needs perfect tension and thickness. If the material is uneven, batteries can fail quickly.

- Cell Assembly: Each cell contains layers stacked on top of each other with almost no room for mistakes. If layers touch or don’t line up, you risk short circuits or low storage power.

- Module/Pack Integration: Cells join together. This is where the battery truly comes together as a unit. Misalignment or loose connections will spell trouble down the road.

A single misstep in these stages not only brings down yield and drives up cost, it can create a safety risk. With the cost of battery recalls reaching millions, precision isn’t just important—it’s everything.

What Are Servo Cylinders and Why Are They Preferred in Battery Production?

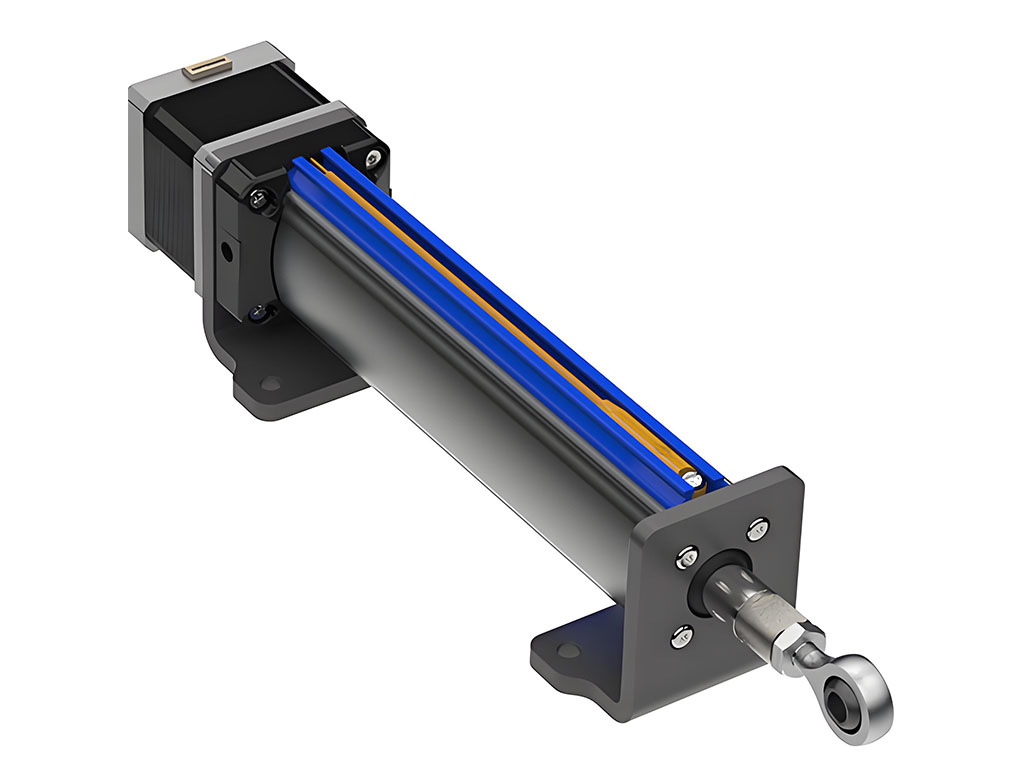

So how do you guarantee that every stage hits the bullseye, every single time? Enter the servo cylinder. But what is it?

A servo cylinder is an electric linear actuator. It works with a smart servo motor and uses an encoder to know exactly where it is at all times. It can move in and out, stop, and change direction—all at the touch of a button or a signal from a controller. The difference? You get closed-loop feedback, so the servo always knows what’s happening and can adjust for perfect position, speed, and force—even down to just a few microns.

Why Servo Cylinders Beat Pneumatic and Hydraulic Actuators

Here’s why automation experts and engineers choose servo cylinders:

- Precision & Repeatability: They can hit the same position within 0.005mm. That’s about the size of a red blood cell. No air leaks, no oil mess—just smooth, precise moves.

- Force & Speed Control: Unlike old-school systems, you can switch force or speed right from the controller. No need for manual tweaks.

- Energy Savings: Tests show electric servo systems use up to 80% less power compared to pneumatic ones because they only use energy when moving.

- Clean Operation: No oil to leak, no air to dirty up your cleanroom. Perfect for sensitive battery making.

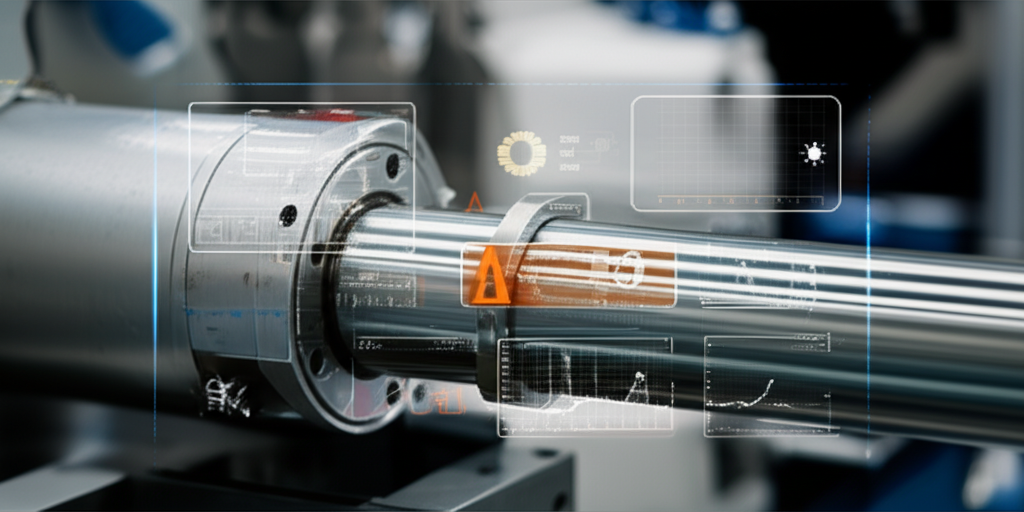

- Data & Diagnostics: Built-in sensors tell operators exactly what’s going on. Engineers can catch a problem early—before it becomes costly.

Pick any top Electric Linear Actuators supplier and you’ll see these benefits on full display. But let’s get even more hands-on.

Core Servo Cylinder Applications Across the Li-Ion Battery Production Line

Want to know where servo cylinders work their magic in the battery world? Here’s a stage-by-stage look:

Electrode Coating and Slitting: Ensuring Uniformity

- Uniform Coating: Servo cylinders keep tension perfect on sheets, holding the coating thickness steady across miles of material.

- Precise Cutting: When slitting coated sheets, servo cylinders guide blades so each cut lands on target. No drifts, no shorts, just clean edges.

- Minimal Waste: Better control means you use less material and slash scrap rates.

High-Accuracy Cell Stacking and Assembly: Building the Core

- Pinpoint Alignment: Each anode, cathode, and separator layer is placed in perfect order.

- Gentle Handling: You can set the servo’s grip so it won’t crush delicate battery layers. Forget expensive failures or rework.

- Automated Pick-and-Place: Robots with servo cylinders pick up and set down parts quickly, smoothly, and with just the right touch.

Electrolyte Filling and Degassing Control: Crucial for Performance

- Exact Liquid Control: Servo cylinders manage tiny valves to fill each cell with the perfect amount of electrolyte, not a drop too much or too little.

- Air Removal: By working with pressure and vacuum systems, they pull trapped air from cells, boosting battery strength and life.

Pouch Cell Sealing and Formation Processes: Securing the Cell

- Sealing: Holding steady force and heat, servo cylinders make sure every seal is airtight. No moisture sneaks in to wreck the battery.

- Formation Curve: They press cells during charging for final shaping—applying just enough pressure, never too much.

Battery Module and Pack Assembly Automation: Scalability and Integration

- Perfect Connections: Welding busbars or tying cells together needs micron-level placement. Servo cylinders don’t miss the mark.

- Cooling and Wiring: With programmable control, installing tricky cooling plates or routing wires is streamlined and repeatable.

- Final Checks: On the last test station, servo cylinders help push, pull, or lift batteries so every unit passes inspection.

If you want to see examples, factories using high-quality Servo Linear Actuator Factory solutions have cut error rates and sped up line changeovers. That’s direct impact you can measure.

Key Benefits of Integrating Servo Cylinders in Battery Manufacturing

Let’s recap the top benefits you’ll see with servo cylinders in your production lines:

- Superior Quality: Products come out right, with fewer mistakes and defects.

- Higher Yields: Less scrap and waste thanks to all that precision.

- Big Power Savings: Lower your monthly bills, since servo cylinders draw only the power they really need.

- Flexible Production: Switch battery sizes or types—just reprogram the servo. No hours lost on machine tweaks.

- Safe and Reliable: Less handling by people cuts accident risk, while built-in sensors catch problems fast.

- Cleanroom Approved: Want ISO Class 6 or cleaner? No problem; servo cylinders are made for these environments—no oil, no dust stirred up.

- Data Feedback: Every move can be tracked, logged, and analyzed for future upgrades. This is the backbone of Industry 4.0.

Challenges and Considerations for Implementation

Great tech always brings a few hurdles. Before you jump in, know this:

- Upfront Cost: Servo cylinders cost more than traditional options. But the jump in quality and yield usually makes up for it within months—not years!

- Integration Work: These systems play well with others, but you need experts who know motion control and factory automation.

- Maintenance: Calibration and setup take some know-how. Trusted partners like Jimi offer training and support, so you’re never stuck.

- Environmental Needs: If your line is extra hot, vibrating, or exposed to electrical noise, tell your supplier—they can help you pick the right specs.

If you want variety, explore options like Ball Screw Actuators and Actuators with Position Feedback to fit every plant need.

Future Trends: Servo Cylinders in Smart Battery Factories

Tomorrow’s battery plants are evolving fast. Here’s what’s ahead:

- Hyper-Automation: Lights-out factories running round-the-clock, with robots and servo cylinders running most tasks.

- AI and Machine Learning: Systems predict problems before they happen and fix them automatically.

- Digital Twins: Virtual plant models simulate everything to help you plan and adjust in real time.

- Green Manufacturing: Lower energy use helps companies hit eco goals while saving money.

Look for the latest Industrial Automation Actuators to see how new options are unlocking powerful, flexible battery lines.

FAQ

What is a servo cylinder and how does it work in industrial automation?

A servo cylinder is an electric actuator that moves with high accuracy. It follows real-time feedback to control speed, force, and position. You tell it what to do—and it listens.

Why are servo cylinders critical for lithium-ion battery production?

Batteries need near-perfect assembly. Servo cylinders offer repeatable, error-free motion—down to the micrometer—so each cell works as designed.

Which battery manufacturing stages benefit most?

Mainly electrode coating, stacking, electrolyte filling, pouch sealing, and module assembly. All the high-precision, high-stakes steps!

How do servo cylinders improve battery quality and yield?

They cut mistakes, keep parts where they belong, and limit waste. Plants using high-end servo cylinders have seen 5-15% better yields.

What are the main advantages over hydraulic or pneumatic actuators?

Servo cylinders are cleaner, more accurate, more efficient, and fully programmable. No leaks, no pressure drops.

Can they run in battery cleanrooms?

Absolutely. Top-tier servo cylinders are oil-free and sealed for ISO Class 6 or higher cleanrooms.

How long do servo cylinders last on busy lines?

With proper care, many models run for millions of cycles, often outlasting the equipment around them.

Is the higher upfront cost really worth it?

Yes. Most companies see quick payback via improved yield, lower scrap, and energy savings.

What’s their role in Industry 4.0?

Servo cylinders give you real-time data. They make smart factories smarter, linking motion, analytics, and AI.

Conclusion & Next Steps

Servo cylinders are the secret behind high-quality, safe, and efficient battery production lines. They handle every step with the care and repeatability you need for today’s booming EV and energy markets. Here at Jimi, we don’t just make servo cylinders—we help battery makers and system integrators unlock new levels of precision, speed, and reliability.

Ready to see how servo cylinders can future-proof your battery production? Explore custom solutions at our China Linear Actuator Manufacturer page and get in touch with our team of experts. Experience the Jimi difference—where your next breakthrough starts with a single, perfect move.