Introduction: The Evolution of Automated Fastening

Think of a busy factory floor. Robots zip around. Screws twist into place in a flash. In modern assembly lines, speed and accuracy mean everything. Yet, old ways—air-powered tools, hand-held drivers—just can’t keep up anymore. They waste energy. They often make mistakes. If you want perfect products, you can’t rely on guesswork or luck. This is where servo cylinders come to the rescue. These smart machines don’t just push—they listen, learn, and adjust with every move.

What Are Servo Cylinders and How Do They Revolutionize Screwdriving?

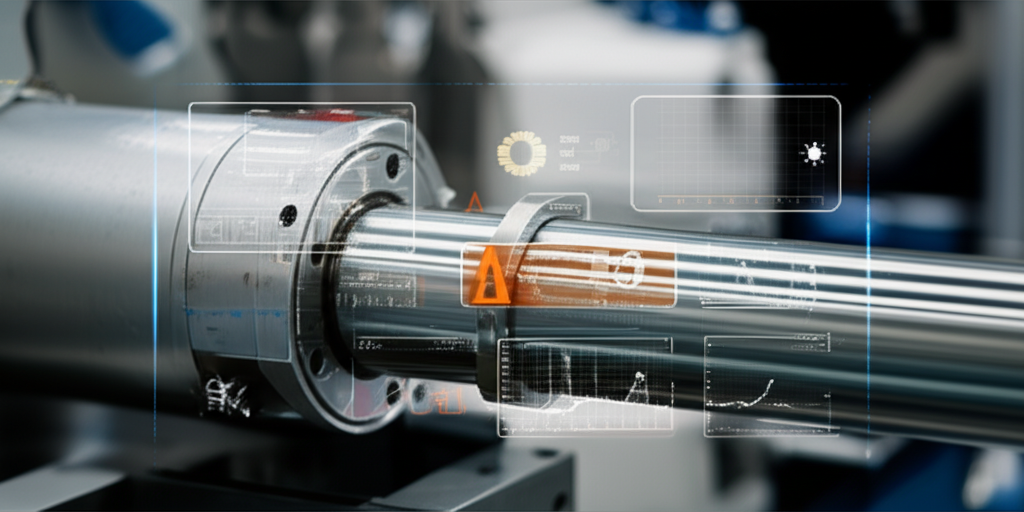

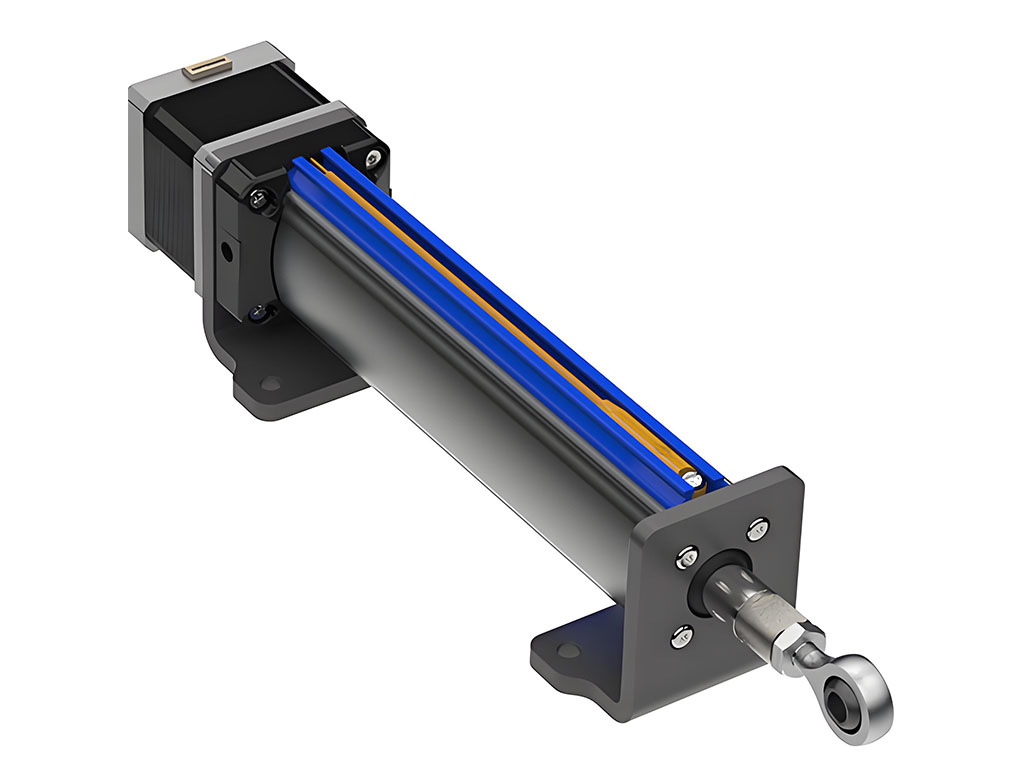

Let’s clear the fog. A servo cylinder is not a magic wand, but it comes close! It’s an electric linear actuator that moves things in and out, up and down. What makes it special? A servo motor drives the show, working with an encoder and controller. That’s a lot of big words, but here’s the big idea: the system checks itself every second. It knows if it’s moving too far, too fast, or not enough.

Unlike old pneumatic tools (which puff air and hope for the best), a servo cylinder follows programmed steps. You decide how much force, how fast, how deep. The cylinder “talks” to a controller, using a feedback loop—like when your body balances a cup of water so you won’t spill. It takes orders from a Programmable Logic Controller (PLC) or a friendly Human-Machine Interface (HMI), so workers and engineers can tweak or watch the action in real time.

And yes, you can use different types—rod-style, rodless, even mini actuators. All these work thanks to electric motors, not air or oil, and fit in tight spots or huge machines alike. For a real deep dive, check out Electric Linear Actuators and Rodless Actuators.

Unpacking the Core Advantages: Why Servo Cylinders Lead the Way in Automated Screwdriving

Precision, Repeatability, and Unmatched Quality Control

Servo cylinders hit the bullseye—every single time. We, at Jimi, have watched these systems get torque accuracy within ±1% and depth control to ±0.05 mm (Bosch Rexroth Whitepaper). You want every screw tight, but never cracked? No problem. Want every assembly the same as the last? That’s standard. This super-fine control means far fewer broken parts or missing screws. Your scrap pile shrinks, and your peace of mind grows.

Speed, Efficiency, and Throughput Optimization

Why crawl when you can race? Servo-driven screwdrivers cut assembly time by up to 20-30% (Atlas Copco Case Study). Plants that made 1,000 products a day can hit 1,150 with the same team. How? Servo cylinders move fast, stop fast, and never miss a step. They go from “start” to “done” without slowing down for coffee breaks or quality checks.

Data-Driven Assembly for Traceability and Process Optimization

Here’s where things get smart. Every twist, every turn, every push gets recorded—torque, angle, depth, even time per screw. Over 70% of manufacturers say real-time data is critical (Grand View Research). Why? If something goes wrong later, you know which screw, which tool, which moment. This helps with quality checks, meeting standards like ISO, and making the next run even better.

Flexibility, Adaptability, and Cost-Effectiveness

Change is hard for old machines. Not for servo cylinders. With a few taps, you can switch to longer screws, bigger boards, or softer plastics. You don’t need new machines—just new instructions. And here’s a hidden gem: servo systems can save up to 80% on energy compared to air-powered tools (Festo Whitepaper). No more leaky pipes and thumping compressors. Savings today, and every day.

Real-World Applications: Where Servo Cylinders Shine in Automated Screwdriving

- Automotive – Building cars is no joke. Airbags, brakes, ADAS modules require tight screws and zero mistakes. Servo systems make sure every bolt gets the right twist.

- Electronics Manufacturing – Smartphones, PCBs, laptops get micro-screws that can’t slip. Servo cylinders offer micro-moves and protect delicate parts.

- Medical Devices – Precision is survival. Surgical instruments and diagnostic gear need gentle, exact force—servo cylinders deliver this every shift (FANUC Medical Manufacturing).

- Aerospace & Defense – Screws hold whole planes and satellites together! You don’t want “good enough.”

- Consumer Goods – Assembly lines for toys, appliances, and tools get faster and more reliable.

If you want to dive into product options for each application, China Electric Cylinder Factory and Servo Linear Actuator Factory offer a wide range.

Key Components and Seamless Integration for Robust Systems

The Servo Motor and Drive System: The Brains and Brawn

Picture your biggest weight lifter—now give him a top scientist’s brains. That’s your servo motor. It uses a screw or belt to turn spin into push. The drive tells it how strong and how far.

Feedback and Control: The Eyes and Central Nervous System

Encoders are like eyes—they tell the system where the screw is. Load cells sense if things are too tight or too loose. The PLC or controller is the brain, ruling over every move.

User Interface and Software: The Human Connection

Operators use simple screens, the HMI, to tell machines what to do or check their work. Easy software lets you program, change, and save jobs—all without a PhD!

Mechanical Design Considerations

Guides and mounts keep everything straight. You’ll find choices for every assembly line—robot arms, fixed stations, or even DIY test benches. See Actuators with Position Feedback and Servo Motor Actuators for more on smart designs.

Key Data Insights from Servo Cylinders in Automated Screwdriving Systems

| Metric | Traditional Pneumatic | Servo Cylinder Solution |

|---|---|---|

| Torque accuracy | ±10% | ±1% |

| Depth control | ±0.5 mm | ±0.05 mm |

| Assembly cycle time | Baseline | -20% to -30% |

| Energy use (lifetime) | 100% | Down by up to 80% |

| Traceable data for every fastener | No | Yes (real-time) |

| Adaptability (changeovers, new parts) | Low | High |

| Payback period | — | 18–24 months |

(Bosch Rexroth Whitepaper, Atlas Copco Case Study, Festo Whitepaper, ABI Research Report)

FAQ

What is a servo cylinder and how does it work?

A servo cylinder is an electric actuator. It uses a servo motor and feedback sensor to move with super high accuracy. You send a command, and the servo moves just right—and checks itself every step.

What are the benefits of using servo motors in screwdriving applications?

You get control and data. Every screw gets tightened perfectly. You save energy. Changing jobs is easy—just reprogram.

How do automated screwdriving systems improve quality control?

They check every step. If a screw is too tight or loose, the system stops. All data is saved, so you can trace problems fast.

What is the difference between pneumatic and servo screwdrivers?

Pneumatic uses air; it’s quick but not precise. Servo uses electric power with feedback, so you get more accuracy, more data, and lower energy use.

Can servo screwdriving systems handle different screw types and materials?

Yes! Change the program, tell it what you need, and go. It adapts to plastic, metal, tiny screws, and giant bolts without missing a beat.

Conclusion & Next Steps

The future has arrived. Servo cylinders in automated screwdriving put you in control—no more costly mistakes or waste. If you want assembly that’s faster, smarter, easier to trace, and energy-saving, the time to act is now. At Jimi Technology, we don’t just sell linear actuators. We build better solutions. Decades of experience, top-quality products, and custom answers for every industry—this is our promise.

Want to start? See our Heavy-Duty Linear Actuators, Actuator Controllers, or contact us for a custom quote. Let’s build the factory of tomorrow today—together.