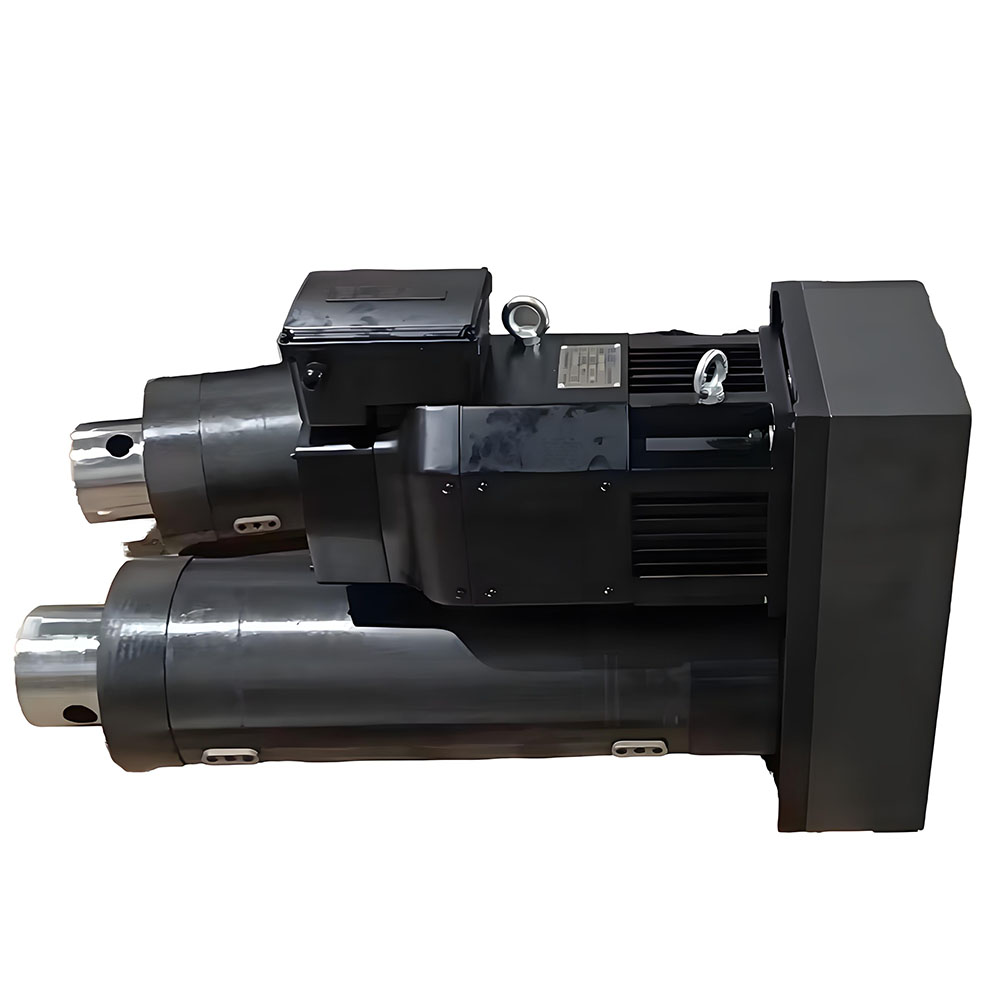

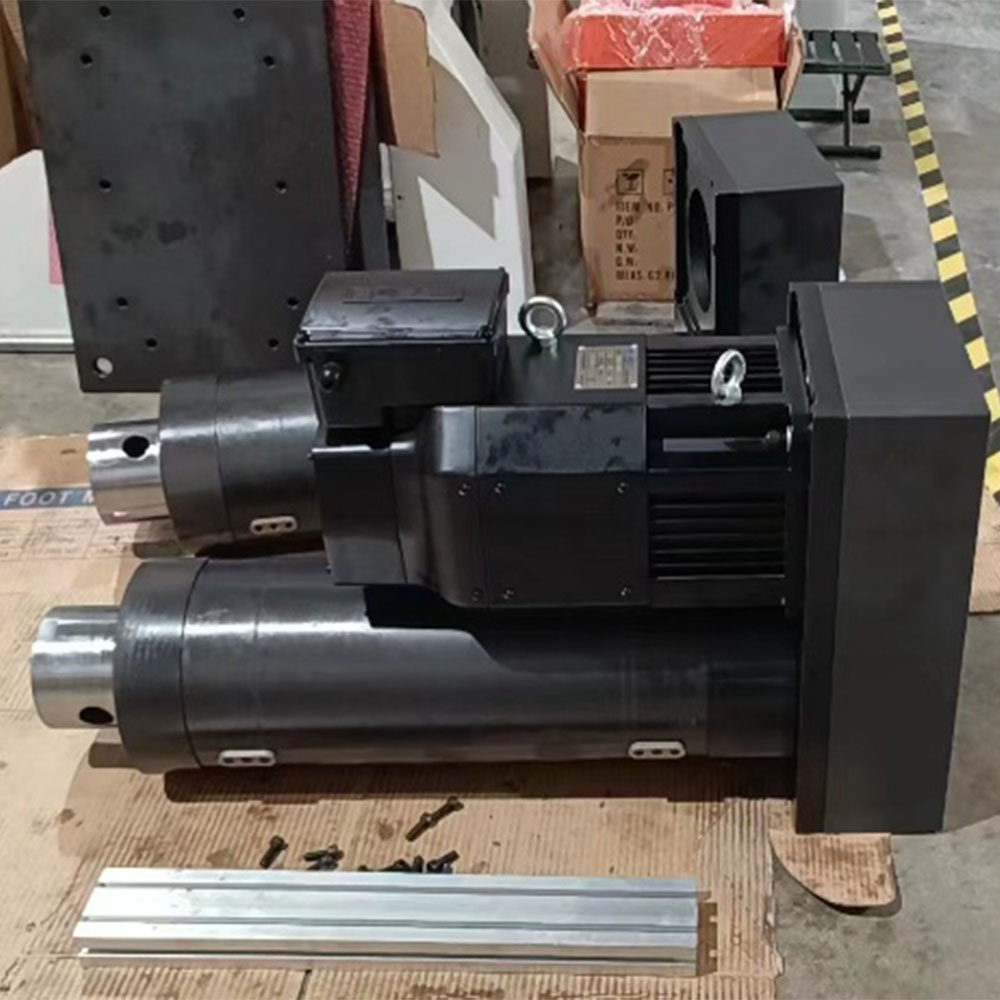

250 Series Max Load Servo Electric Cylinder | Custom Built

Step into a new era of industrial automation with the 250 Series Max Load Servo Electric Cylinder from Jimmy Technology. This heavy duty linear actuator is designed for those who demand extreme force, pinpoint precision, and fully customizable solutions for their toughest automation challenges.

Description

Step into a new era of industrial automation with the 250 Series Max Load Servo Electric Cylinder from Jimmy Technology. This heavy duty linear actuator is designed for those who demand extreme force, pinpoint precision, and fully customizable solutions for their toughest automation challenges.

Features and Benefits

-

Rugged Max Load Capacity: Engineered for the highest forces across our portfolio, the 250 Series is your answer to applications requiring a high force electric actuator. Its heavy duty linear actuator design ensures unwavering performance, even under the heaviest loads.

-

Precision Servo Motor Control: Our state-of-the-art servo motor linear motion system delivers exceptional position control, velocity regulation, and force feedback. Closed-loop control and high-resolution encoders mean your process gets reliability, accuracy, and repeatability—every single cycle.

-

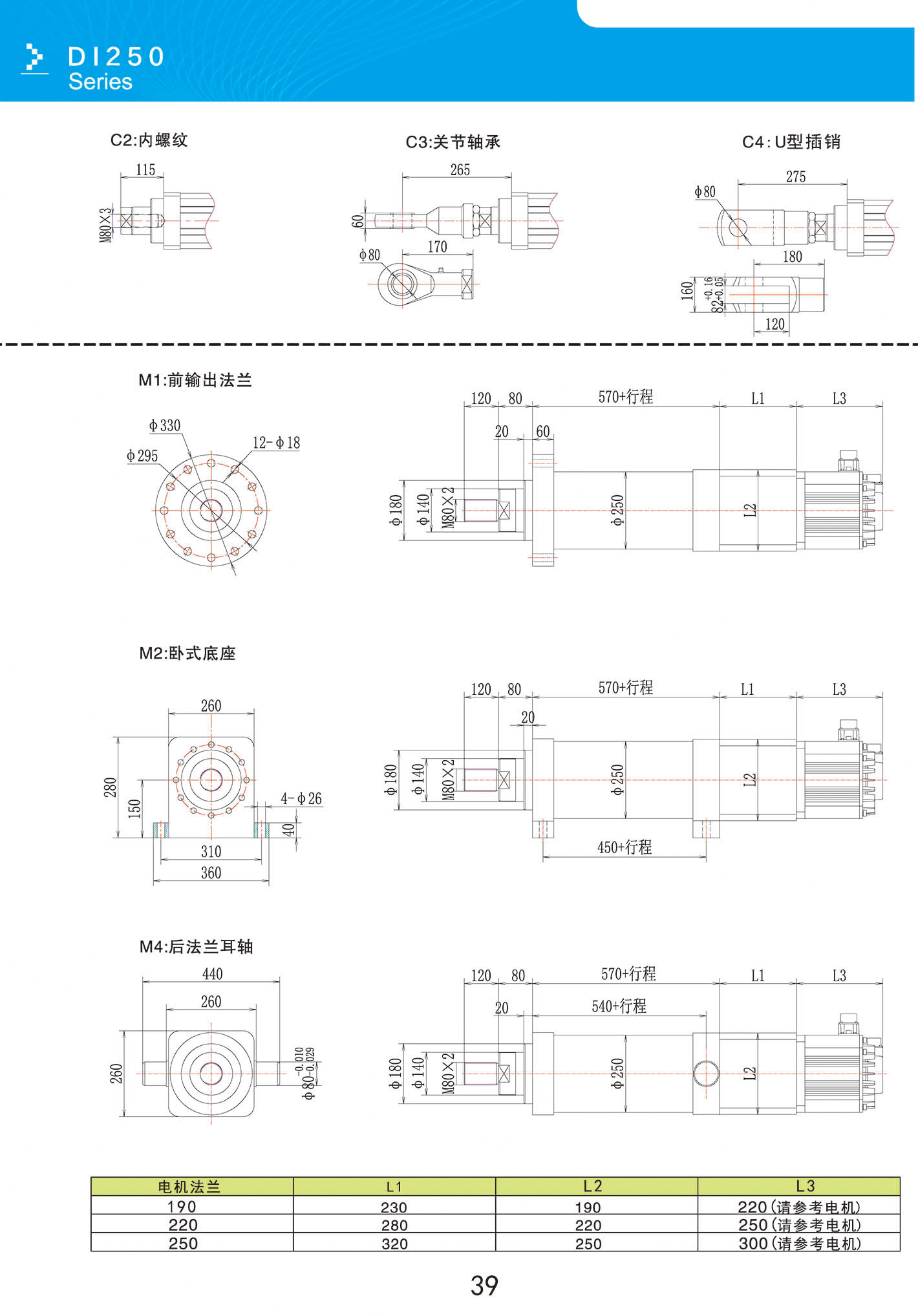

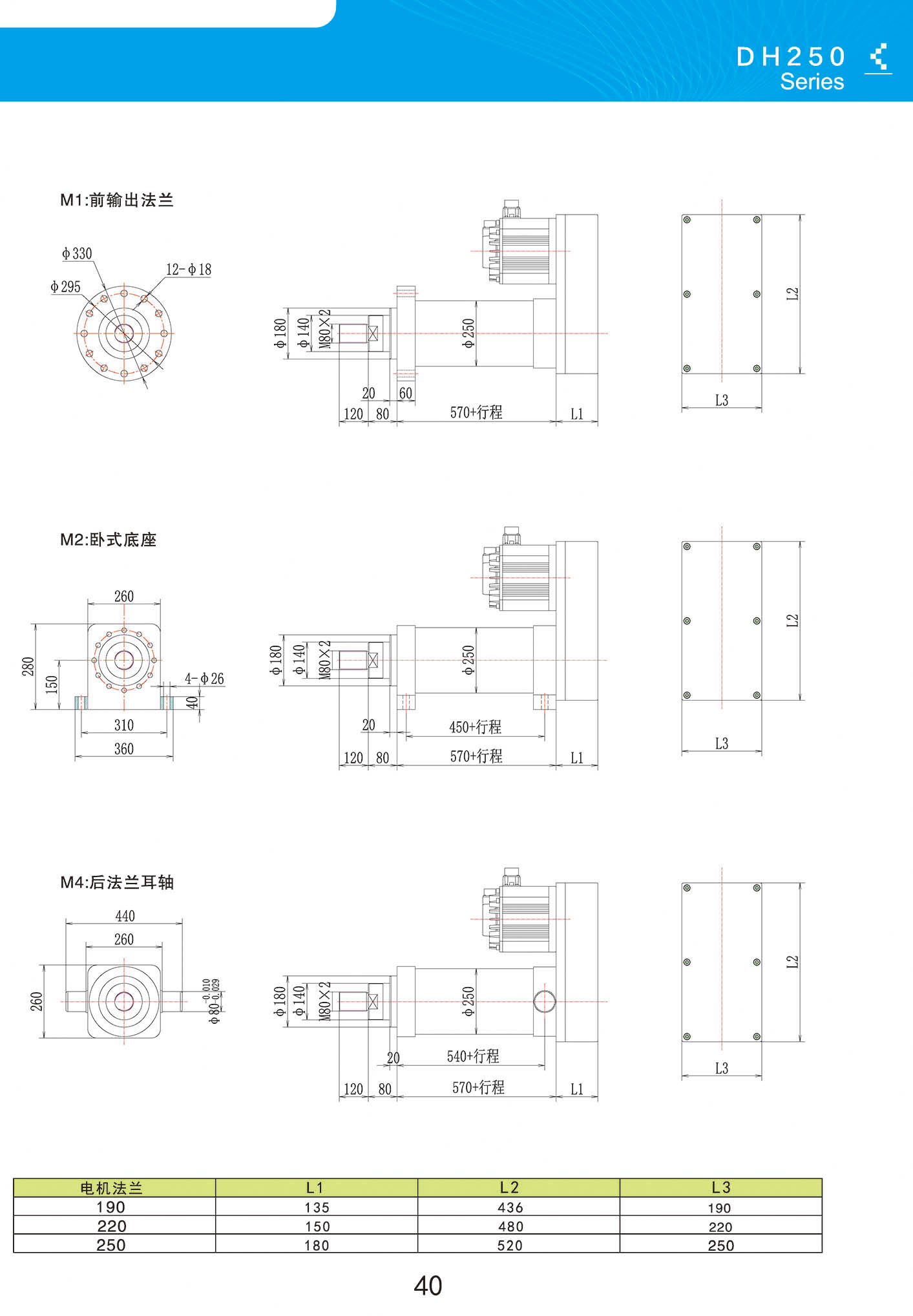

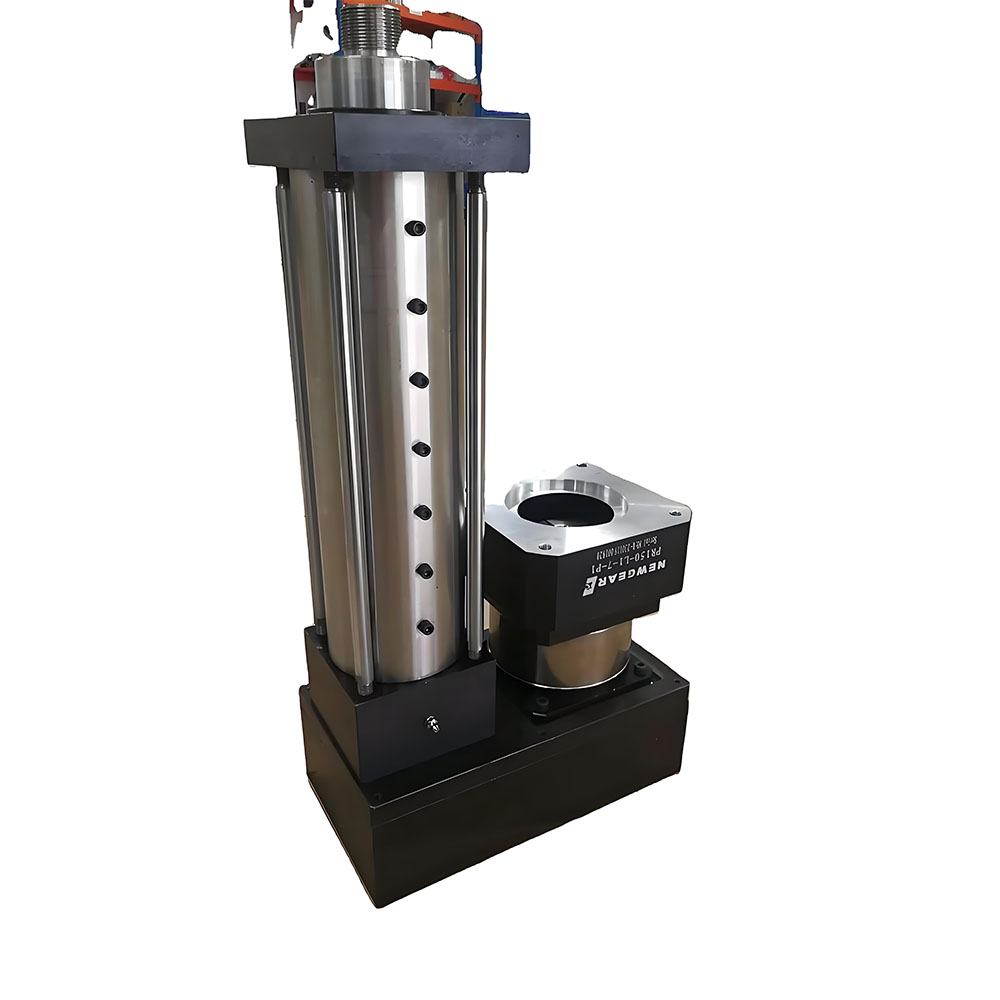

Custom-Built Versatility: This is not a one-size-fits-all actuator. Jimmy Technology tailors every 250 Series to match your specific requirements. Opt for custom strokes, mounting, rod end, and anti-rotation options; choose a roller screw or ball screw drive; integrate your preferred servo motor, encoder, or fieldbus—no matter how complex the challenge, we engineer a built-to-order linear actuator just for you.

-

Built for Harsh Environments: Constructed using stainless steel and high-grade aluminum alloys, the 250 Series shrugs off corrosion, impact, and daily abuse. Its IP65-rated enclosure seals out dust and water, so you can deploy it in washdown zones, outdoor installations, or any harsh environment without hesitation.

-

Energy and Maintenance Savings: You’ll immediately notice the operational benefits—a programmable electric actuator that’s up to 90% more energy efficient than hydraulic or pneumatic systems, and requires little to no maintenance. Eliminate the headaches of fluid leaks, filter changes, and seeping seals.

-

Advanced Safety and Smart Features: Need back-driving prevention or overload protection? How about integrated brake options, anti-rotation mechanisms, absolute or incremental encoders, and predictive maintenance support? The 250 Series covers every base for industrial automation and beyond.

Wide Applications

The 250 Series Max Load Servo Electric Cylinder is the customizable electric cylinder of choice for automotive manufacturing (press lines, welding, assembly), heavy material handling (palletizing, industrial lifting), primary metals (furnace automation, rolling mills), timber processing, aerospace, robotics, test stands, packaging machinery, and wherever engineered linear solutions demand turnkey performance and total reliability.

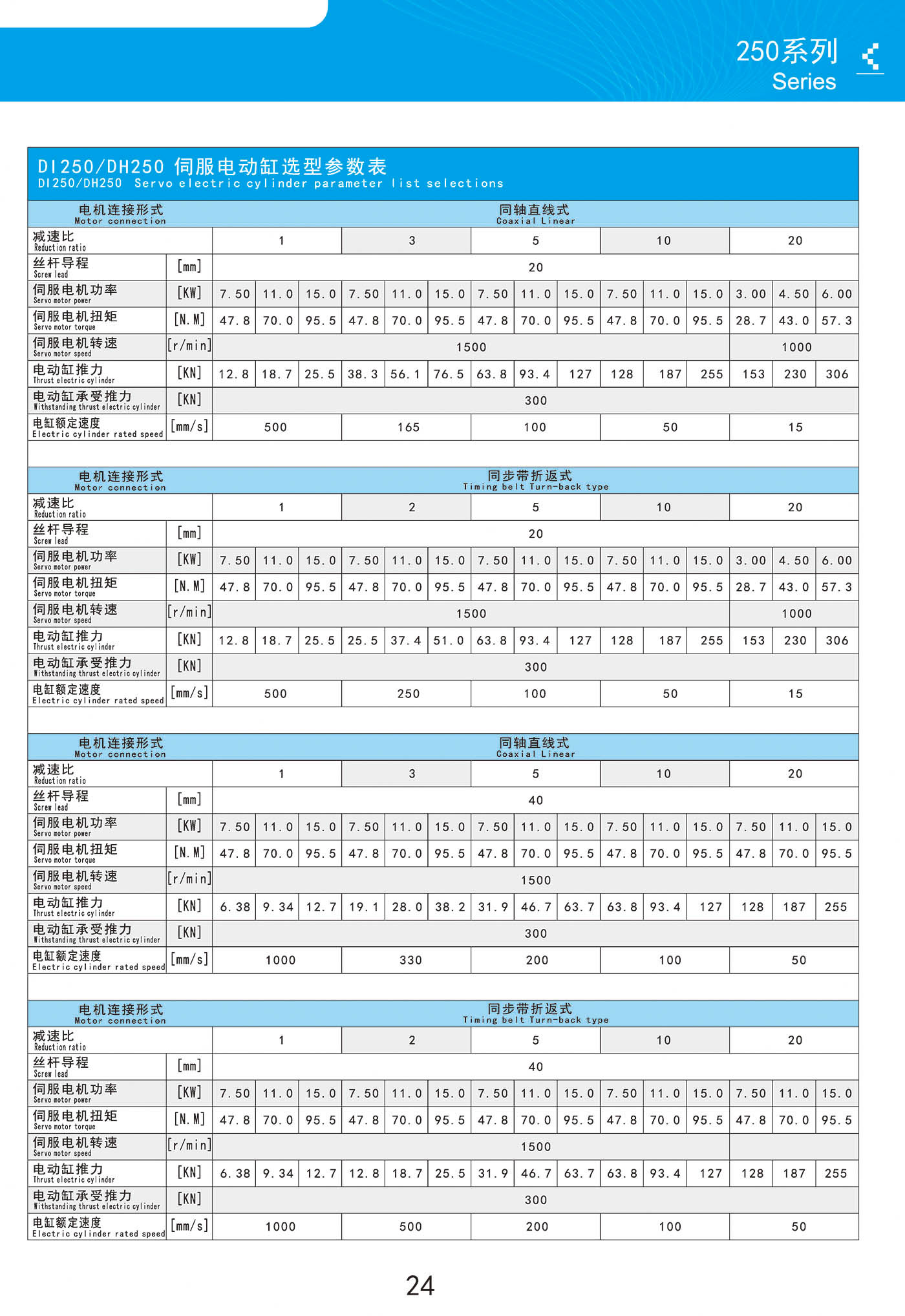

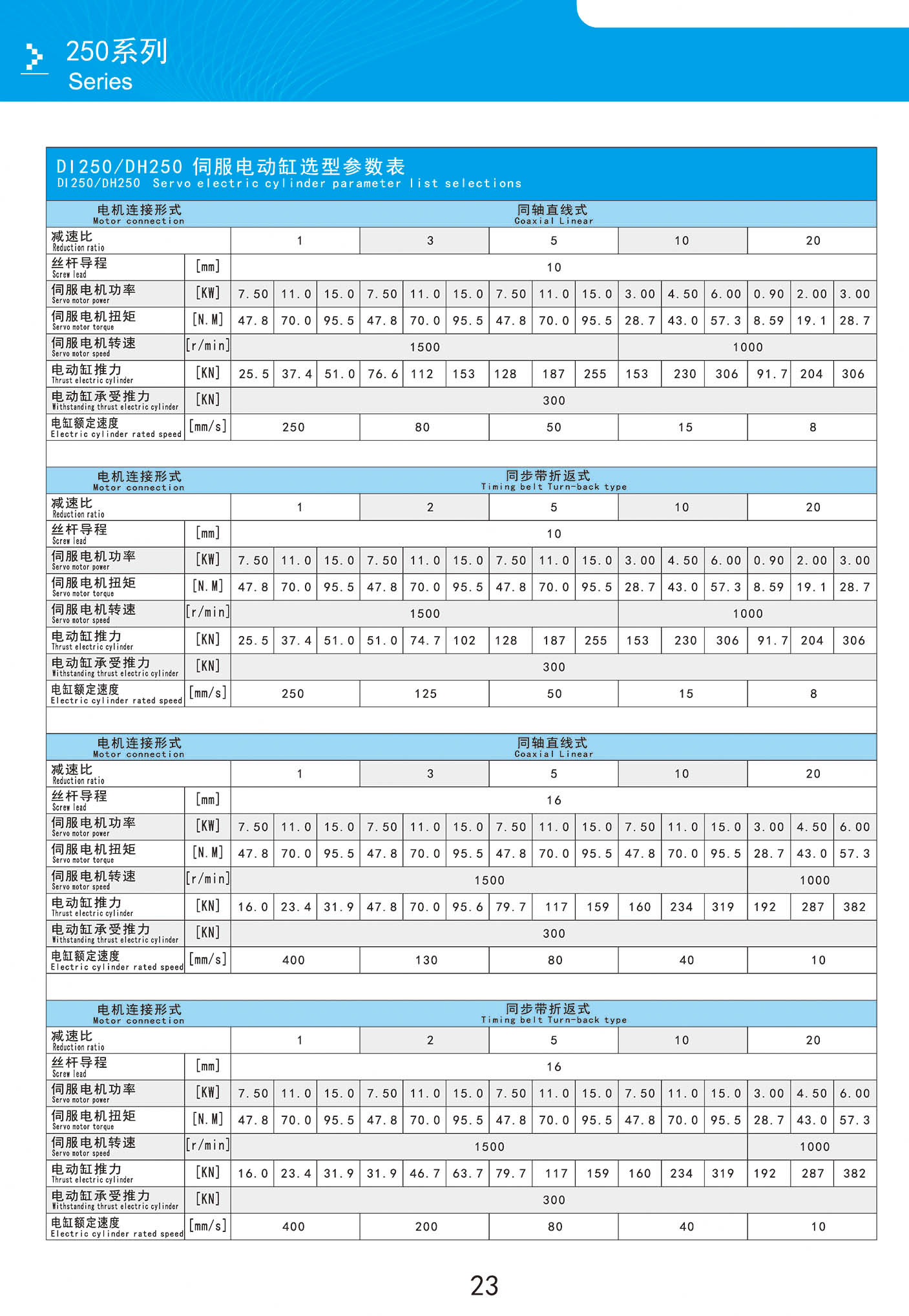

Specifications

- Force: Peak thrust and continuous force ratings available up to 250 kN (56,000+ lbs); custom options available for your application’s max load requirements.

- Speed: Up to 1000 mm/s, tailored to user need and load specifics.

- Stroke Length: Engineered per project—short, long, or anything in between.

- Input Voltage: Fully customizable—AC and DC servo motor integrations, compatible with global standards.

- Protection Rating: IP65 (standard), with options for higher ratings or ATEX certification for explosive atmospheres.

Technical Support

Jimmy Technology backs every 250 Series Max Load Servo Electric Cylinder with end-to-end technical support. We provide detailed CAD models, technical datasheets, integration guides, and wiring diagrams. Our expert engineering team partners with you from concept to commissioning—ensuring seamless system integration, no matter how complex your application.

Conclusion

When you choose Jimmy Technology, you invest in market-leading quality, true innovation, and proven reliability—powering your automation projects forward with confidence.