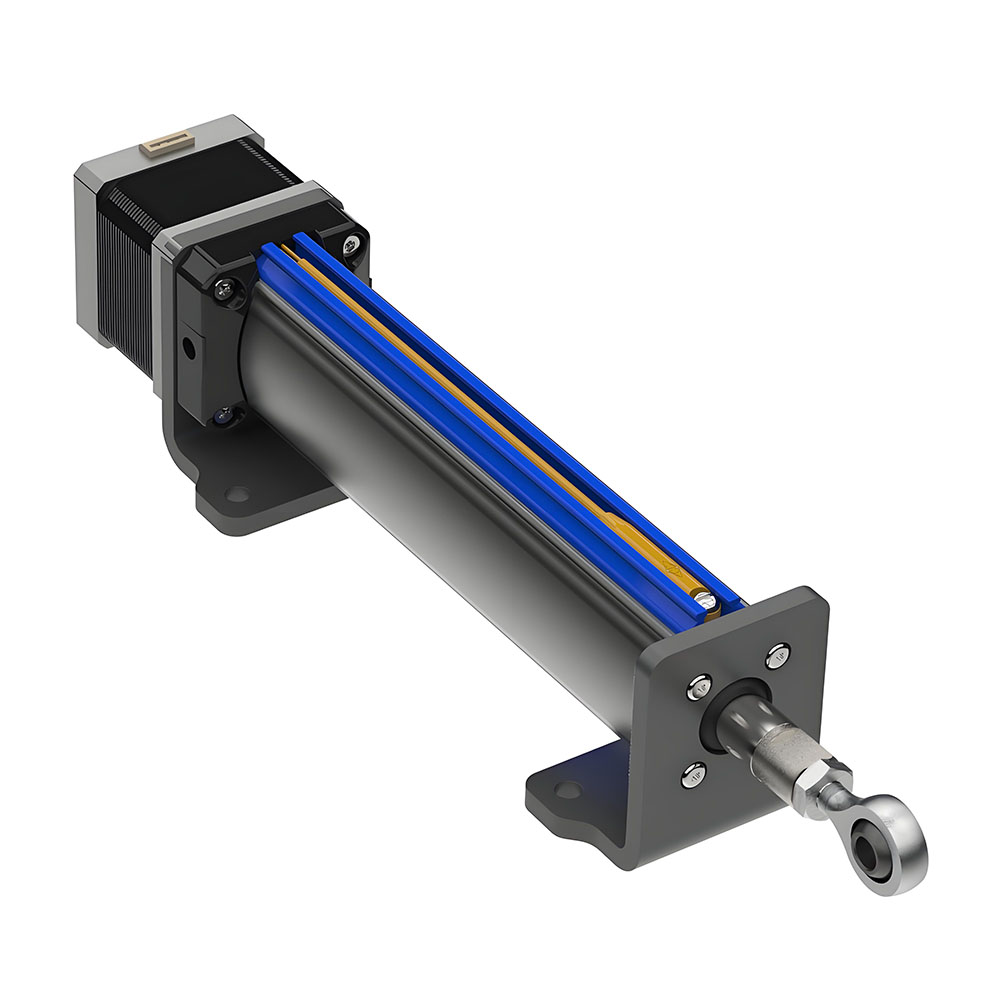

250 Series Custom Electric Cylinder | 30T Servo Actuator

Meet the 250 Series Custom Electric Cylinder. It delivers a relentless 30-ton thrust with pinpoint servo precision for high-force, repeatable motion.

描述

Meet the next benchmark in industrial automation: the 250 Series Custom Electric Cylinder. Engineered to deliver relentless 30-ton (300kN) thrust with pinpoint servo precision, this actuator redefines what’s possible for high-force, high-repeatability linear motion applications.

Features and Benefits

- Built for Power and Precision: With a robust 30-ton force output and advanced closed-loop servo control, this electric linear actuator 30T empowers you with industrial-grade performance—ideal for demanding press, forming, and material handling tasks. You get repeatable, reliable motion with high thrust and accuracy every single cycle.

- Heavy-Duty, Rugged Construction: The 250 Series takes durability seriously. Its heavy-duty housing, precision bearings, and optional stainless steel or high-grade aluminum construction ensure a long life in harsh environments where uptime is critical.

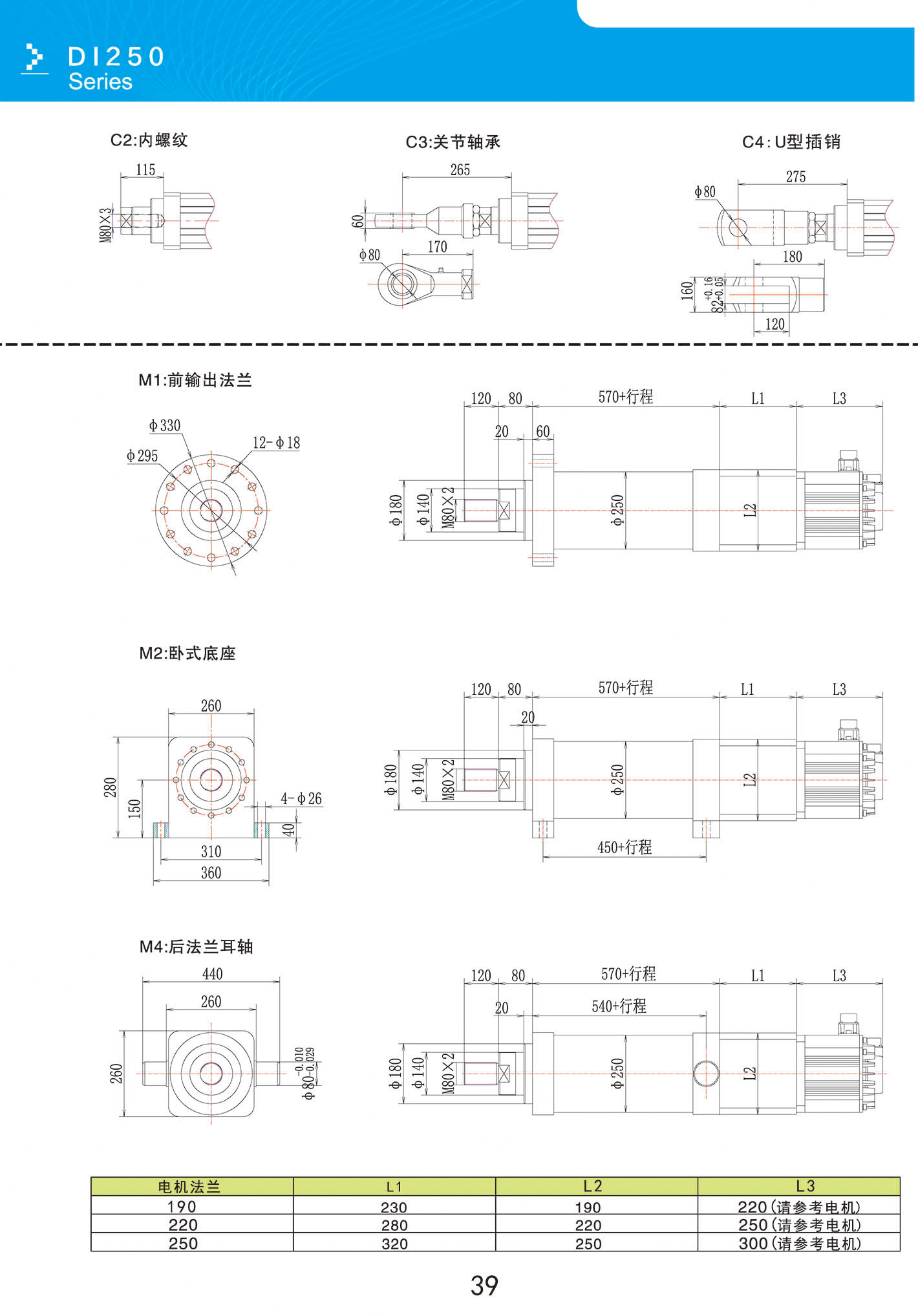

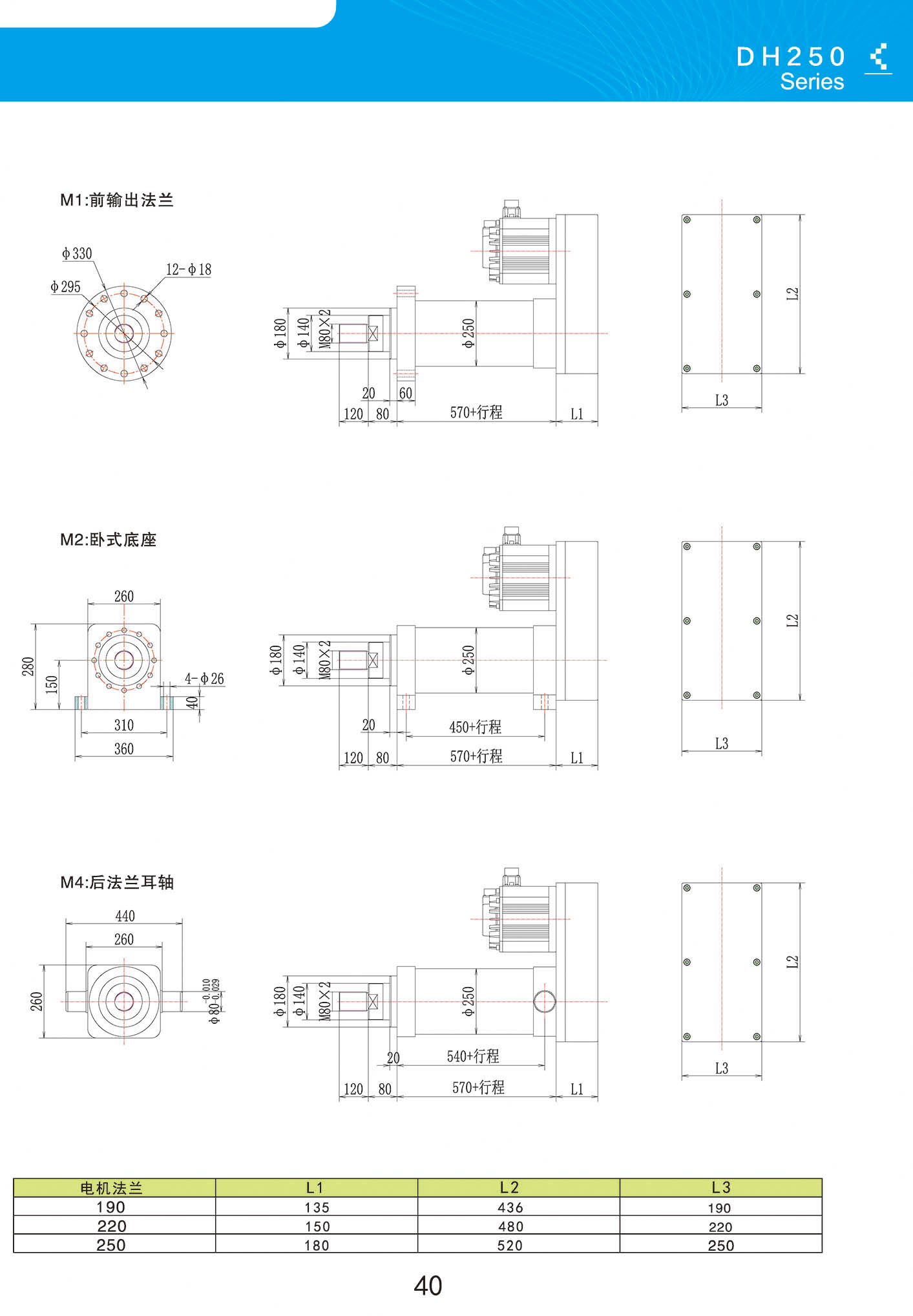

- Versatile Customization: Need a unique stroke length? Custom motor mounting (inline, parallel, or integrated)? Specific IP67 protection or water cooling? The 250 Series adapts to your process—making it the top custom electric cylinder manufacturer for OEM and tailored solutions.

- Energy Efficient and Maintenance-Free: Swap out hydraulic or pneumatic systems for a sustainable automation solution. This advanced electric actuator is up to 90% more energy efficient and virtually maintenance-free—no messy oil, no leaks, just clean, reliable motion.

- Smart Connectivity and Integration: Connect to EtherCAT, PROFINET, or EtherNet/IP fieldbuses with ease. Integration with major PLC and HMI platforms is seamless, powering up your automated manufacturing lines, robotic presses, and digital motion control systems.

- Quiet, Safe Operation: Low noise levels improve operator comfort, while built-in limit and position sensors (absolute/incremental encoders) enable advanced safety and diagnostics. Stay compliant, stay efficient.

- High Precision, High Speed: Achieve fine positioning accuracy (up to ±0.01 mm) and rapid acceleration, all with programmable, closed-loop control over force, speed, and position.

Wide Applications

This heavy-duty electric cylinder is the gold standard for automation in metal forming, electric forming press cylinders, injection molding, testing equipment, automated assembly lines, heavy material handling, and more. Use it for stamping, riveting, core pulling, fatigue testing, and even aerospace or automotive manufacturing—where precision meets power and customization is key.

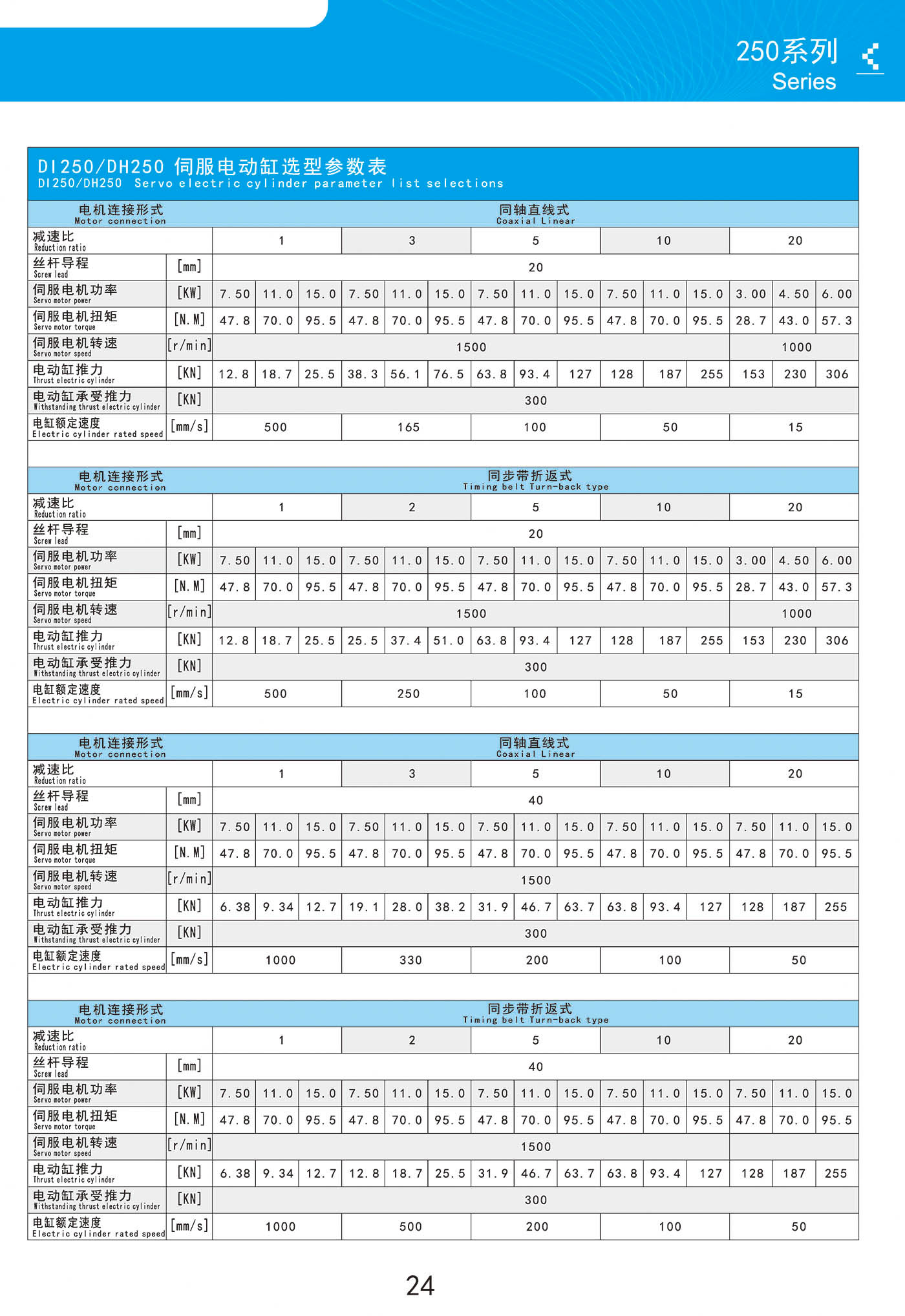

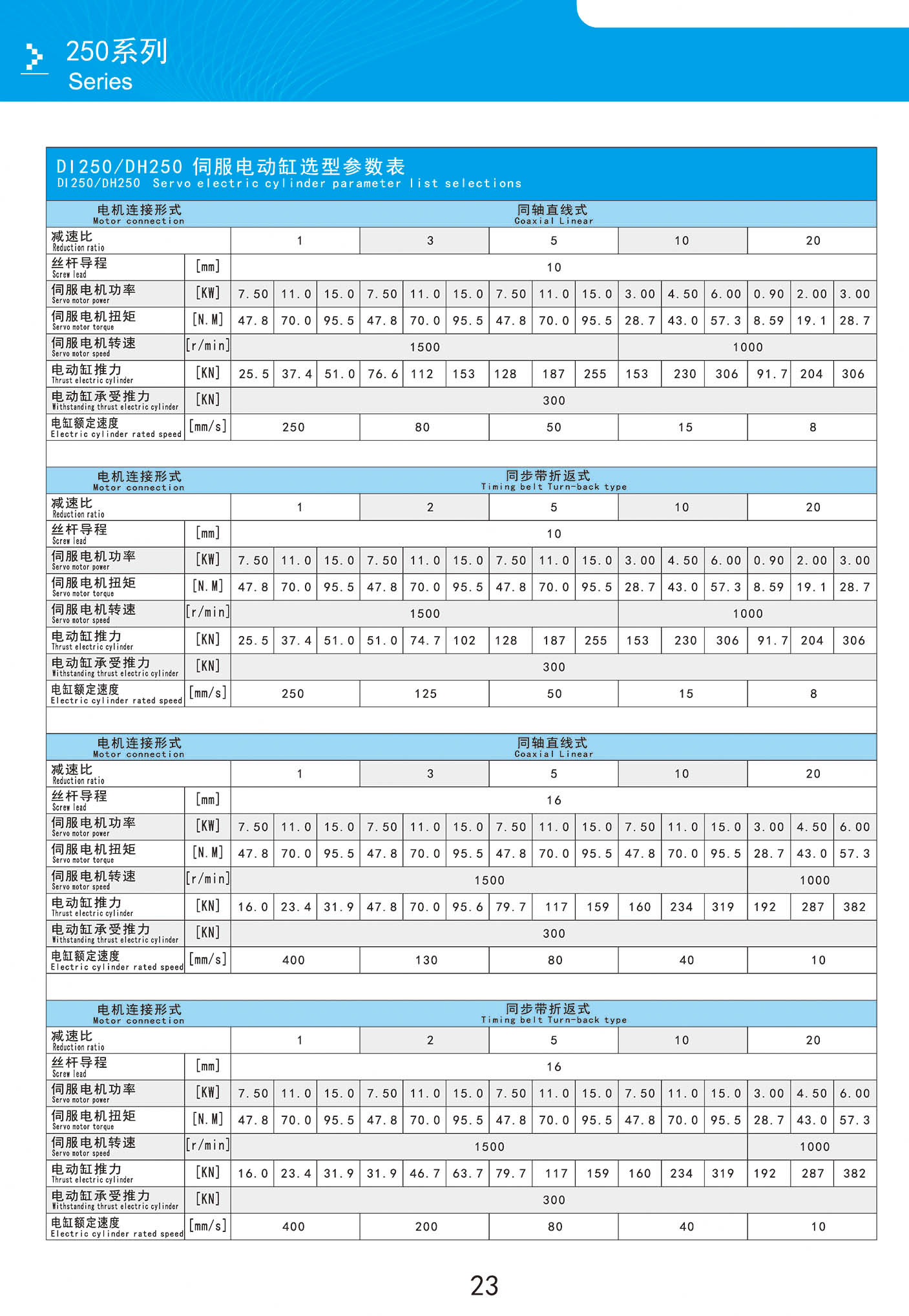

Specifications

- Force: 30T (300kN) continuous force output; peak force up to 45T (450kN) where required.

- Speed: Programmable ranges tailored to your process (subject to custom build).

- Stroke Length: Fully customizable—options up to 2000mm available.

- Input Voltage: Compatible with most industrial voltages, including 400VAC three-phase.

- Protection Rating: IP65 to IP67 (customizable); suitable for dusty, wet, or harsh industrial environments.

Technical Support

We provide comprehensive technical support with every actuator, including detailed CAD models, application-specific datasheets, and clear wiring diagrams—making your integration with motion control software and PLC systems as smooth as possible.

Conclusion

Choosing Jimmy Technology means trusting your automation to unmatched force, ultra-precise control, and industrial-grade reliability—exactly what you need for the most demanding high-force linear motion solutions.